Why You Should Use Toggle Clamp Injection Molding Machine

2023/05/08 By Topstar

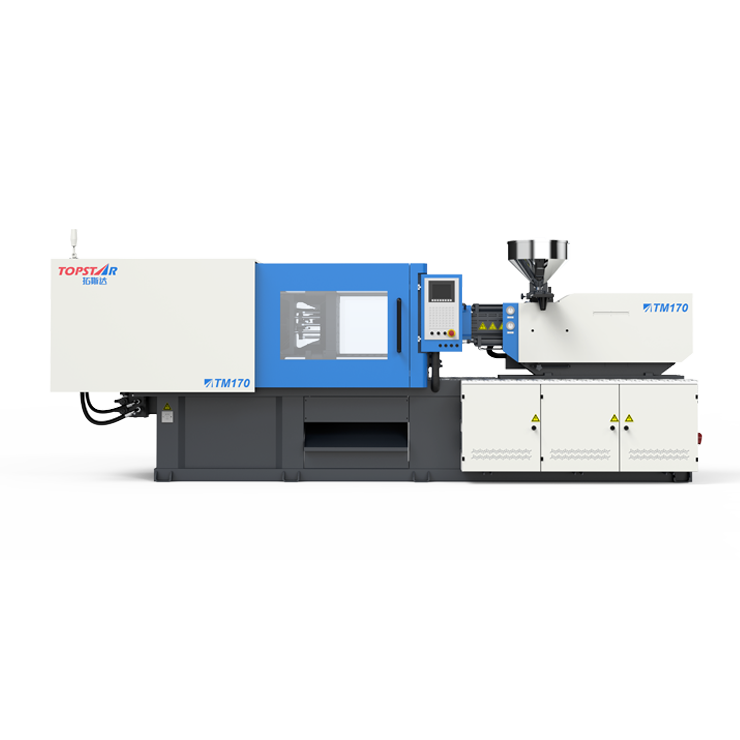

A toggle clamp injection molding machine is an excellent tool for starting a manufacturing business. They can create various products and allow you to set up your production line in your shop or garage. These affordable machines come with unique features to meet your business needs.

To learn more about toggle clamp injection molding machines and how they can help you get started in the manufacturing industry, read on!

It is one of the most efficient tools in the injection molding process!

Toggle clamp injection molding machines are one of the most efficient tools to use in the injection molding process. They have many benefits and advantages over other devices used in this process. It’s a tool that’s been around for decades, but it’s still used today because it delivers excellent results.

Toggle clamp injection molding machines use clamps to hold parts together while they melt at high temperatures in an oven. This allows you to speed up production time and reduce costs, so multiple people don’t need to work alone. With just one operator handling all aspects simultaneously, it all happens instantly!

It is an automated version of a traditional clamping system!

It is an automated version of a traditional clamping system. The toggle clamp holds the mold open during the injection process, allowing molten plastic to flow under high pressure into the cavity in the mold cavity.

The toggle clamp injection molding machine provides high precision and repeatability in producing complex, large parts that require tight tolerances between mating surfaces. It also helps manufacturers reduce overall cycle times by up to 30 percent compared to traditional presses. It can be costly because they require more time spent on setup procedures before creating parts out of plastic resin material (such as polypropylene).

Toggle Clamp Injection Molding Machine is a machine that has a low cost per part ratio!

It is a machine with a low unit cost of parts that will last for years without issue. It works in an automated way, not manually. This means you don’t have to do any work on it manually; instead, let the machine do everything for you!

It produces large parts with high performance and efficiency thanks to its unique design, allowing operators to quickly assemble/disassemble tooling and fixtures as needed during machining operations, so there are no delays between each cycle.

The toggle clamp injection molding machine offers high precision and repeatability!

It provides high precision and repeatability when producing large parts. Toggle clamp injection molding machines are suitable for making large parts. Its design allows the operator to easily adjust the position of injection molded components to obtain a precise fit between them.

This machine works by clamping plastic components with clamps that move vertically along rails on both sides of an assembly line. After each step, another set or pair of clips is moved down until all four sides are closed. This process ensures that all edges line up perfectly every time you make a product!

Toggle Clamp Injection Molding Machine has a longer service life than other machines!

It is durable, lasts longer than other machines on the market, and is suitable for large and small parts. The toggle clamp injection molding machine has a low cost per part ratio compared to other machines available. It does not require any additional tooling changes during production runs and reduces labor costs by eliminating manual handling tasks associated with traditional methods of part assembly.

The toggle clamp system uses two types of clamps: “toggles” (or “dog” jaws) and “stops.” A toggle has two opposing flat surfaces, compressed together when it engages with its corresponding stop; this compression holds parts securely while they travel through an assembly line or die setter (which may have multiple stations).

Final

This is a great option for those who want to get started with injection molding but don’t have enough money for a giant machine. The few points described above tell you that toggle injection molding machines are perfect for beginners looking for something affordable or businesses that don’t want to spend too much on equipment. You can read more product articles on our website.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/05/08

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/05/08

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/05/08

- Topstar Special | National Science and Technology Workers Day 2023/05/08

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC