What is the weight and dimensions of an injection molding robot?

2024/05/08 By Topstar

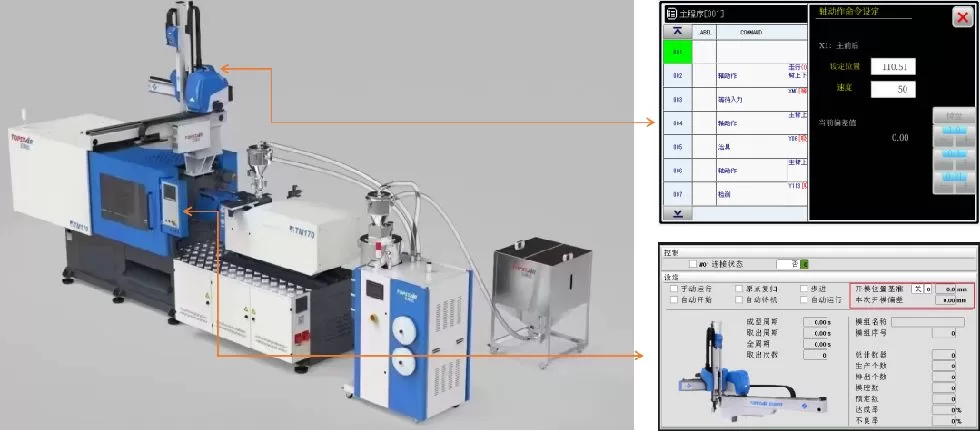

Injection molding robot are usually placed on top of injection molding machines, so their size and weight are critical to manufacturers. In addition to specific functions, many purchasers will also focus on the weight and size specifications of the injection molding robot. So, in this guide, we will introduce the size and weight range of Topstar injection molding robots.

Typical dimensions of injection molding robots

Generally speaking, the size of an injection molding robot can vary greatly depending on its design, functionality, and capacity. The EU series, which is the most cost-effective among Topstar, has a length of only about 2060 mm x 2240 mm and a height range of 1650 mm to 1770 mm. It is suitable for grabbing items with a load range of 6kg. Its main arm’s up-and-down stroke is 800-900 mm, and its up-and-down standby is 225 mm. Its operating dimensions, range of motion, and the safety area required for safe operation determine its physical footprint.

Weight specifications

The weight of an injection molding robot varies as much as its size and is closely related to its structural complexity and the robustness of its design. In the EU series, its weight is in the range of 260-300KG. The main arm is made of lightweight and high-strength A6061 material, which reduces its weight by 20% compared with traditional manipulators, thus improving the overall operating performance. This lightweight main arm material allows a minimum removal time of 1.5 seconds when grabbing products. At the same time, the lighter weight will not cause much trouble during transportation and installation.

Dimensions and Weight Impact of Installation on the Injection Molding Machine

The size of an injection molding robot determines, to a large extent, its range of motion. Choosing the correct size is crucial to ensure the injection molding robot can perform the required tasks without overstretching or unnecessary movement. This can reduce the injection molding machine’s Injection molding cycle times and increase productivity. At the same time, its weight will also affect the stability and vibration level of the injection molding machine during operation. If the weight is too heavy, it may cause significant vibration, affecting the accuracy and quality of the molded parts.

Optimize production layout

Knowing its size and weight, we can optimize the production layout to achieve significant operational efficiencies. A targeted layout reduces cycle times, minimizes the movement required between tasks, and promotes better workflow management. Once installed, a robot of the right weight and size can easily receive and deliver injection molded parts without unnecessary delays or rerouting. It is important to note that you must design the layout within the workshop to maintain high safety standards in all operations. This includes allowing adequate clearance for emergency stops and operator intervention without creating a safety risk due to the robot’s operating area.

Established long-term considerations

One last thing to note is that when sizing an injection molding robot, it is important to consider current and potential needs in future production. Because your production line requires different mold design specifications when changing products. The weight of the injection molding robot directly affects the structural requirements of the factory workshop and its attached machinery. Heavier robots require strong support systems to handle the increased stress and prevent mechanical failure. In the long term, you will need to evaluate the load-bearing capacity of the existing structure and possibly reinforce it to accommodate future upgrades to multiple pieces of equipment.

Get ready for integration

Choosing an injection molding robot of the right weight and size is critical to preparing your equipment for successful automation integration. After understanding the relevant weight and dimensions, you can ensure that the robot you choose can be well installed on the injection molding machine to perform picking and placing tasks.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/05/08

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/05/08

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/05/08

- Topstar Special | National Science and Technology Workers Day 2024/05/08

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC