What is the function of the injection molding machine robotic arm?

2024/03/06 By Topstar

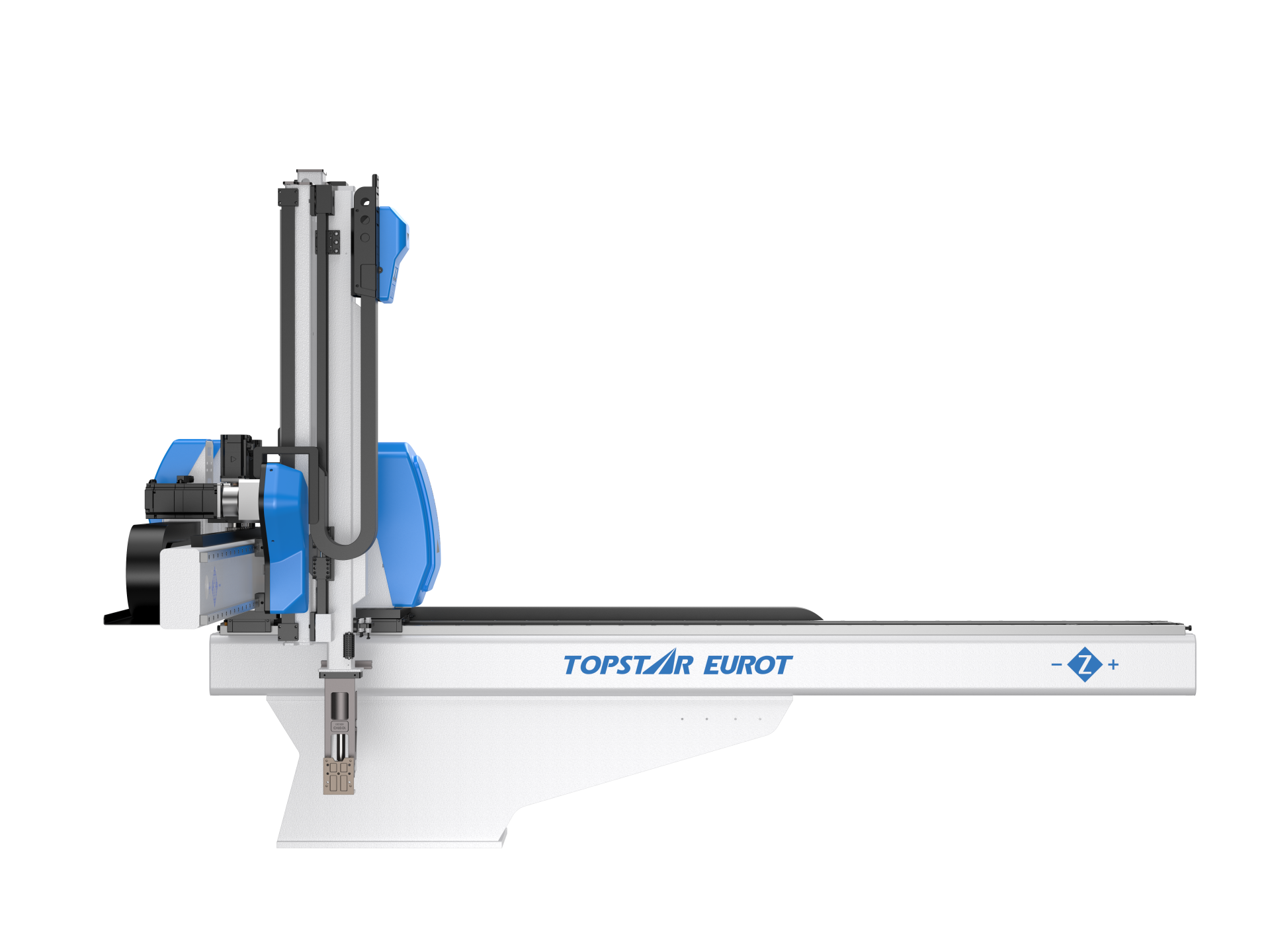

In the production process of plastic products, injection molding has become a viral and widespread production process. One of the core technologies for this process is the injection molding machine’s robotic arm, which uses automation to replace manual labor in the entire production process to grab and transfer plastic parts. This guide provides in-depth answers to the functions, advantages, and importance of injection molding machine robotic arm in modern injection molding manufacturing.

Injection molding machine robotic arm automation improves efficiency and productivity

The robotic arm of an injection molding machine is an integral part of injection molding and can perform various tasks, such as removing and placing parts accurately and quickly. This involves removing molded parts from the injection molding machine and placing them on conveyors or pallets. Compared with manual operation, the main advantage of the injection molding machine’s robotic arm is that it shortens the cycle time of grabbing parts and increases output. Improve productivity and increase production by automating repetitive tasks, allowing manufacturers to meet demand more efficiently.

Ensure precision and consistency of part placement

Injection molding machine robotic arms also ensure the accuracy of part handling and placement during injection molding. These robotic arms are equipped with sensors and actuators to achieve precise and repeatable movements controlled by the control system. Using high-rigidity precision slide rails and high-strength steel belt transmission, predetermined trajectories and motion trajectories can be followed with millimeter-level accuracy, allowing them to grab, manipulate, and position parts with extremely high precision. Ensures part handling and placement without delay errors.

Injection molding machine robotic arm enhances safety in manufacturing environment

The advent of robotic arms for injection molding machines enhances the safety of the manufacturing environment by reducing the risk of accidents associated with manually picking up parts. The robotic arm has advanced safety features and technology to create a safer operator working environment. The safety of injection molding machine robotic arms can reduce operator contact with overheated or dangerous parts during the injection molding. They are located above the injection molding machine to grab and transfer work and can quickly move away from areas of high temperature, molten plastic, or moving machinery. Additionally, we equip the injection molding machine robot arm with safety functions such as collision detection, an emergency stop mechanism, and a protective barrier.

Facilitates integration and connectivity of injection molding machines

Modern injection molding machine robotic arms have a communication protocol system that enables data exchange and communication between the robotic arm and the injection molding machine control system. They have sensors, actuators, and communication interfaces to facilitate real-time data exchange and feedback between the two systems. It enables the injection molding machine to communicate instructions, commands, and production parameters to the robotic arm. In contrast, the robotic arm provides feedback to the injection molding machine regarding its status, performance, and operation. In addition, the injection molding machine robot arm helps coordinate and synchronize the movements between the robot arm and the injection molding machine during the production process. For example, part removal placement synchronized with the injection molding machine’s cycle time and operating sequence. This ensures both systems’ smooth and efficient operation, increasing overall production throughput.

Flexibility and adaptability

The role of injection molding machine robotic arms also enables manufacturers to quickly adapt to changing production requirements. Their flexibility and adaptability allow them to handle various sizes, shapes, and configurations of plastic parts.

Manufacturers can equip robotic arms with interchangeable end-of-arm tools such as grippers, suction cups, or custom-designed fixtures to accommodate different part geometries and handling requirements. This versatility allows manufacturers to produce a diverse product portfolio efficiently while reducing setup time and maximizing overall equipment efficiency.

Ultimately

From this, we know the injection molding machine robot arm is indispensable in modern injection molding. They enable automation to ensure the accuracy of part gripping and increase production operations’ safety, connectivity, and flexibility. This allows manufacturers to improve productivity and work efficiency significantly.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/03/06

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/03/06

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/03/06

- Topstar Special | National Science and Technology Workers Day 2024/03/06

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC