What is the difference between an injection molding hopper dryer and a dehumidifier?

2024/02/28 By Topstar

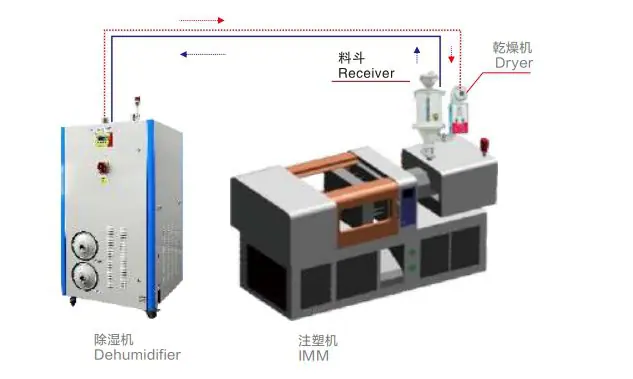

The complete injection molding process includes the injection molding machine and the injection robot, which also consists of the injection molding hopper dryer and dehumidifier. Because moisture in plastic raw materials can significantly affect the quality and integrity of the finished product, two standard tools used for this purpose are injection plastic bucket dryers and dehumidifiers. In this guide, we will explain the differences between these two machines and the characteristics each has.

Learn about the functions of an injection molding hopper dryer:

The injection molding hopper dryer is suitable for drying plastic granules. It uses high-temperature hot air to process raw materials and fully dry them. A dryer comprises a hopper or chamber where one places a plastic resin for drying. Hot air circulates through the hopper, heating the resin and evaporating any remaining moisture within the material. In addition, the plastic hopper dryer has precise temperature and airflow control mechanisms to meet different drying conditions. Users can also adjust temperature settings to meet the specific requirements of various plastic resins and prevent overheating or thermal degradation. Likewise, the control panel changes the airflow rate to provide even drying.

Design, composition, and operation of injection plastic hopper dryer

The main components of an injection molding hopper dryer include the hopper, heating element, blower or fan, temperature and humidity sensors, and control panel. They design all stainless steel raw material contact surfaces to ensure they do not contaminate the raw materials. There is also a viewing window outside the barrel base to observe the internal working conditions directly. It also adopts the curved design of the upward-blowing dryer’s heating tube to avoid damage caused by raw materials falling into the tube. It has safety protection devices for things such as over-temperature and overload.

In terms of operation, the injection molding hopper dryer is generally located above the injection molding machine and dries the plastic resin through a set process. Plastic resin is loaded into the hopper through an automatic loading system, and drying parameters, including temperature, airflow, and drying time, are set on the control panel according to the specific requirements of the resin to be dried. During the drying process, the conditions in the hopper can be monitored through the viewing window or humidity sensor, providing real-time feedback to the control panel.

Understand the functions of dehumidifiers

Manufacturers use dehumidifiers with hot air dryers to perform high-efficiency dehumidification and drying operations on highly hygroscopic engineering plastics (such as Nylon, PC, PBT, PET, etc.). Effectively remove moisture from plastic resins by combining desiccant technology and airflow systems. Desiccant materials, such as silica gel or molecular sieves, absorb moisture from the air inside the dehumidifier, reducing the relative humidity to the desired level. In this process, low-humidity air circulates through a hopper or drying chamber, where it contacts the plastic resin, absorbing moisture from the material and reducing its moisture content to the desired level.

Dehumidifier design, composition, and operation

The main components of a dehumidifier include a drying chamber, a honeycomb dehumidification wheel, a regenerative heater, a blower, and a control panel. The PID temperature control system can accurately control the regeneration temperature and ensure the stability of the dew point. In contrast, the double cooler structure can ensure lower return air temperature and dew point. A return air filter inside ensures that raw material dust does not contaminate the honeycomb runner. The silicone adsorption honeycomb dehumidification allows the regeneration temperature to be only 180°C, which is more energy-saving. The overall design structure is simple and compact, saving space and making it easy to move.

The dehumidifier loads plastic resin into the dehumidifier and then sets the drying parameters on the control panel according to specific requirements. The dehumidifier rotor continuously rotates to absorb moisture from the air inside the dehumidifier. The regenerative heater periodically heats the dehumidification wheel to remove moisture and restore its adsorption capacity. A blower or fan circulates air through the dehumidifier, ensuring the resin is exposed to dry air and effectively removing moisture from the material.

Distinguish the energy efficiency between the two

Differentiating between a dehumidifier and an injection molding hopper dryer requires energy efficiency and cost-effectiveness considerations. While both machines are designed to remove moisture from plastic resins, they employ different technologies, increasing energy consumption and operating costs. Dehumidifiers require more energy to power the desiccant rotor and the blower or fan that circulates air through the machine. While desiccant dehumidifiers have excellent moisture removal capabilities, they tend to use more energy than other drying methods. On the other hand, injection molding hopper dryers do not require energy to power heating elements and blowers or fans, so their energy consumption is generally lower.

To achieve simpler, higher efficiency and lower energy consumption, we combine the two to realize the functions of dehumidification, drying, and feeding. Using a microcomputer makes operations more straightforward, the performance more stable, and it can meet different customer needs.

Ultimately

This guide introduces the differences and design components between the two. With the emergence and popularization of the automation industry, more and more people use three-in-one dehumidification dryers to work in the production line, which can save work efficiency. , making the operation easier.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/02/28

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/02/28

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/02/28

- Topstar Special | National Science and Technology Workers Day 2024/02/28

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC