What functional-size injection molding robot is suitable for me?

2024/03/25 By Topstar

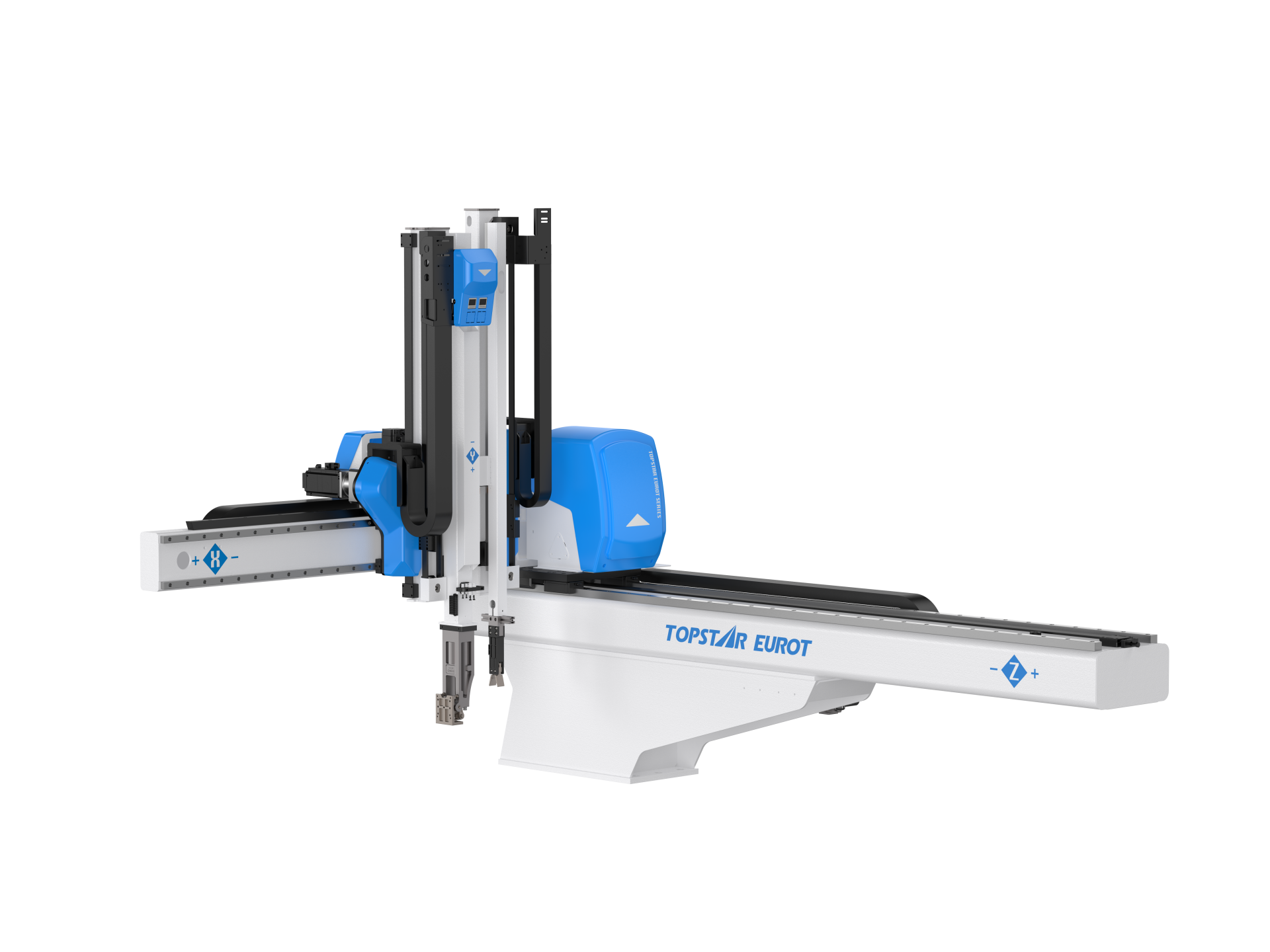

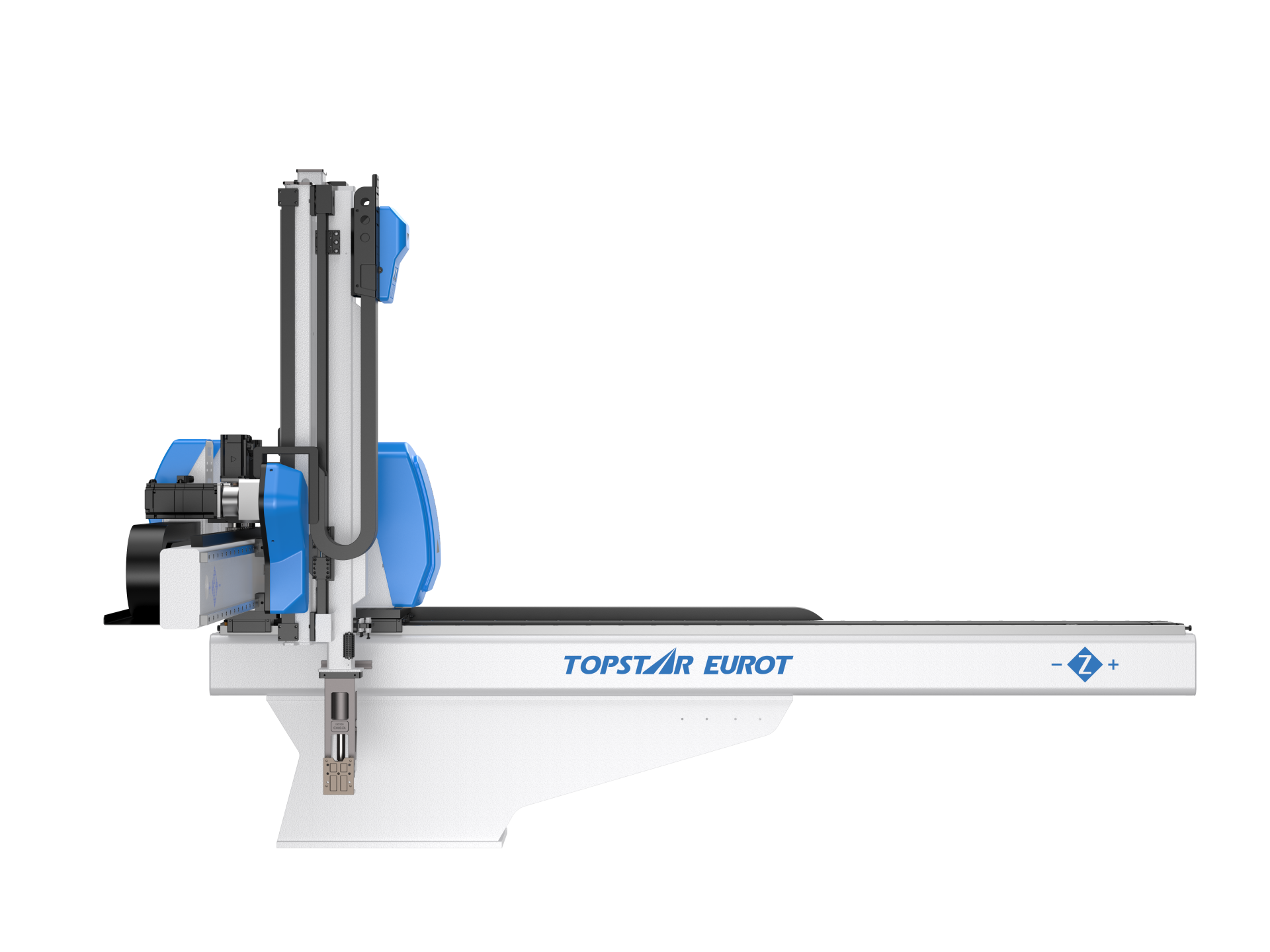

An injection molding robot is an automated robot used to replace manual labor in the injection molding process to grab, pick, and place raw materials and products. It can significantly simplify the production process and improve work efficiency. Different industries and injection molding machines should use robots with corresponding specifications and functions. So, how do you choose the robot that suits you and determine which functions are suitable for you? This depends on some relevant factors, which we will share below.

Evaluate the size and weight of your molded plastic

When you choose an injection molding robot, you must consider the size and weight of the plastic product you are molding. If you are producing more significant parts, you will need a robot with a more extended reach and higher payload capacity; if you are making smaller parts, you will need a robot with a shorter range and lower payload. Injection molding cycle time and throughput also influence the choice of injection molding robot. High cycle times require robots with higher speed and agility to meet production demands. Injection molding robots with advanced control systems and programming capabilities can optimize your cycle times and maximize throughput.

Consider workspace constraints and injection molding machine compatibility.

The injection molding robot is installed above the injection molding machine to work, so we must also consider the space and compatibility of the injection molding machine. Factors such as the distance between the injection molding machine platens, the injection unit’s height, and the mold cavity’s position will all affect the robot’s positioning to the molding machine. If there is insufficient match between the two, the capture will not be in place, and an emergency stop will occur. Additionally, manufacturers must consider overhead clearance and access to auxiliary equipment when positioning the robot within the workspace. They must thoroughly assess the available space, identifying potential obstacles or limitations affecting robot placement and operation.

Safety features of injection molding robots

Injection molding robots with safety features protect operators and equipment. Modern injection molding robots have collision detection systems that use sensors or cameras to detect obstacles or obstacles in their running paths. They can automatically stop or adjust the robot’s movement when accidents and collisions occur, preventing collisions with machines or other objects. Some injection molding robots also have safety controllers that monitor and control safety functions throughout the robot’s operation. These controllers oversee various safety-related tasks such as emergency stop functions, interlocking systems, and collision detection algorithms.

Injection molding robot with intelligent manufacturing

The arrival of Industry 4.0 has made injection molding robots more intelligent. Injection molding robots with smart sensors and connectivity functions can collect real-time data on machine performance, process parameters, and product quality. This enables previous data transmission and analysis of different equipment, promoting remote monitoring, predictive maintenance, and proactive optimization of manufacturing processes. Using an Internet connection, they can oversee production processes, monitor equipment status, and troubleshoot problems from anywhere. Operators can access real-time dashboards, receive alerts, and remotely adjust robot settings or parameters through their application interface.

Vibration suppression function of injection molding robot

As a professional injection molding robot technology consultant, I am pleased to introduce you to vibration suppression, a key feature of modern injection molding robots designed to improve precision, stability, and quality in the manufacturing process. The active damping system used by injection molding robots can detect vibration through sensors and use actuators to generate reaction forces to reduce the impact of external vibrations on the handling and placement of parts. Manufacturers can integrate passive damping components, such as vibration-absorbing materials or dampers, into the robot’s structure or end-of-arm tooling to reduce vibrations transmitted from the molding machine or other sources.

Choose the robot that’s right for you

When choosing an injection molding robot, the most important thing to consider is the plastic parts you produce and the type of injection molding machine. Next are robots with intelligent manufacturing production, safety, and vibration suppression functions. Meet current production needs while providing scalability and adaptability in your manufacturing environment.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/03/25

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/03/25

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/03/25

- Topstar Special | National Science and Technology Workers Day 2024/03/25

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC