What are the latest advancements in injection molding robot technology?

2024/10/21 By Topstar

Analysts expect the injection molding robot market to grow by $109.2 million between 2023 and 2028, with a CAGR of 4.36%. Driven by the increased productivity and efficiency brought about by intelligence and various advanced technologies, the functions of these robots are constantly expanding, providing different manufacturers with innovative solutions to meet the needs of modern industrial intelligent production. This blog post will tell you about the latest technological advances in injection molding robots from Topstar.

Automation and AI enhancement of injection molding robot

Under the influence of Industry 4.0, the latest technological advances in the entire injection molding robot market are nothing more than integrating automation and AI. These technologies enable robots to perform tasks with minimal human intervention, improving production efficiency and reducing labor costs. For example, modern injection molding robots can analyze data from the injection molding process to identify inefficiencies or potential problems. By leveraging machine learning, these robots can predict maintenance needs and dynamically adjust operations, ensuring consistent quality and reducing downtime. This level of automation enables manufacturers to scale up production while maintaining high standards quickly.

The system is more intelligent than the injection molding robot

Topstar uses a self-developed control system on the injection molding robot, which supports software upgrades and updates and supports the injection molding machine to call the robot signal to achieve integrated linkage and more precise control. In addition, a dual system is built in, which customers can freely select, and particular required actions can be programmed. The upgrade of core component technologies such as control systems and servo drives, hardware precision energy saving, software integrated communication, and a more comprehensive range of application scenarios have been achieved, moving from automation to intelligence and becoming a standard item for injection molding factories to upgrade future automation.

More flexible expansion

Topstar’s injection molding machine robot technology has come to the fifth generation. Our R&D team has launched the “five-in-one servo drive” technology, which directly enables one servo drive to control five servo motors and more precise removal control. This drive uses only 3 CPU chips, realizing a five-axis-in-one design. Each CPU chip controls two axes, and the maximum power of each axis is 750W. This provides mighty power for the injection molding robot. At the same time, the multi-axis standard busbar design improves energy efficiency by 20%.

The fully self-developed five-in-one servo drive offers more robust algorithms, precision, energy efficiency, and smarter performance. Compared with the previous generation, it has functional solid scalability and can add back-end automation processes according to customer needs. It adopts advanced motion control technology (contour mode control) to ensure smooth and precise movement according to the predetermined contour when executing complex trajectories or paths.

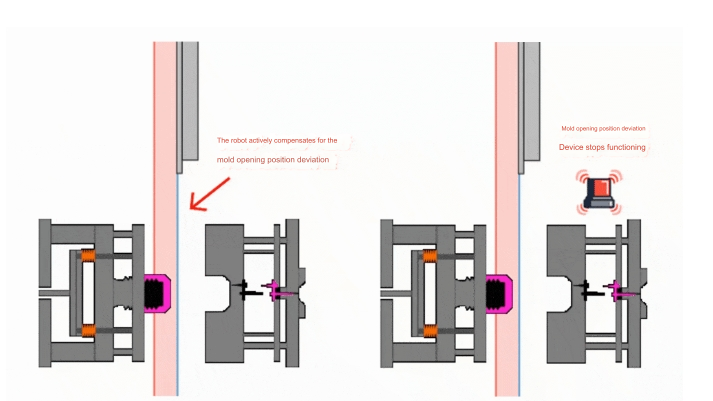

Safer operation

To enhance the safety of the injection molding robot during operation, we adopt joint soft floating protection technology to improve its ability to withstand torque that exceeds the set limit.

In addition, we equip the injection molding robot with a visual system that detects obstacles and adjusts its movements accordingly. This capability reduces the risk of accidents and injuries in the workplace. If the operator is too close, the safety sensor can stop the operation to ensure a safe working environment.

Improvements in sustainability and energy efficiency

Manufacturers are increasingly focusing on sustainability and advances in injection molding robot technology, which aim to improve energy efficiency and reduce waste. Modern robots are designed to consume less energy during operation, which helps reduce operating costs and environmental impact.

The energy-saving servo motors used in Topstar’s injection molding robots can precisely control movement while minimizing energy consumption. These motors can adjust their output according to the task, resulting in significant energy savings during low-demand periods. In addition, advances in material handling technology allow robots to optimize the use of raw materials and reduce waste during production.

Change your injection molding production.

Topstar’s injection molding robot technology allows customers to achieve process assurance from raw materials to finished products, providing customers with efficient and stable production and making injection molding easier! From enhanced automation and artificial intelligence integration to the birth and adoption of “five-in-one servo drive” technology, these innovations are helping all types of plastic machinery optimize operations and meet changing market needs.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2024/10/21

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2024/10/21

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2024/10/21

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/10/21

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar