What are the disadvantages of traditional injection molding robots?

2024/04/24 By Topstar

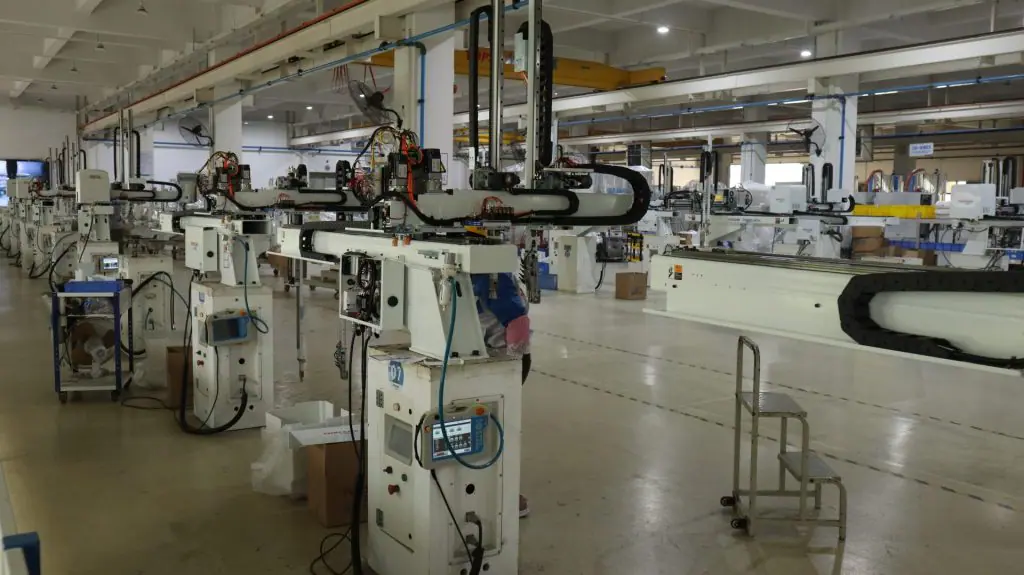

Injection molding robots can replace humans in grabbing, picking, and placing products during injection molding. They have become the key to improving production efficiency and product consistency. However, with the advancement of technology, traditional injection molding robots in the past will have certain limitations in some cases, and problems such as shutdown and collision will affect the entire injection molding· process. So, in this article, we will discuss their various shortcomings and tell you the characteristics of modern injection molding robots.

Traditional injection molding robots have limited flexibility

Although traditional injection molding robots can solve the automation problem, one of their major limitations is that they are limited to repetitive tasks. These robots operate according to fixed sequences and follow programming for specific, unchanging movements. This method is often very effective for production with unchanged injection molding requirements, however, in an environment where product design changes, this becomes a limitation and requires manual reprogramming by skilled technicians. Without extensive manual and equipment adjustments, you cannot adjust them to handle various mold sizes.

Traditional injection molding robots have limited speed!

The speed limitations of traditional injection molding robots stem from their mechanical design and drive systems. They typically feature servo motors that can perform repetitive, precise movements but lack the durability and reliability required for continuous operation. Their mechanical nature limits their ability to accelerate and decelerate, which can slow down their overall cycle times, especially when dealing with complex or multi-part processes. The weight of a traditional injection molding robot’s arm also affects its speed limit. They typically feature heavier mechanical components that require more moving time, slowing down operations.

Energy efficiency issues

In terms of energy consumption during operation, although they use servo motors for movement, they have high precision and power consumption, especially when running continuously in long-term production operations. The energy required to drive these servo motors increases significantly with the size and weight of the robot. Another factor that contributes to energy inefficiency is their inherent rigidity in operation. They are often task-specific and have little flexibility; therefore, they cannot adapt to changes in energy use in production.

Characteristics of the new generation of injection molding robots

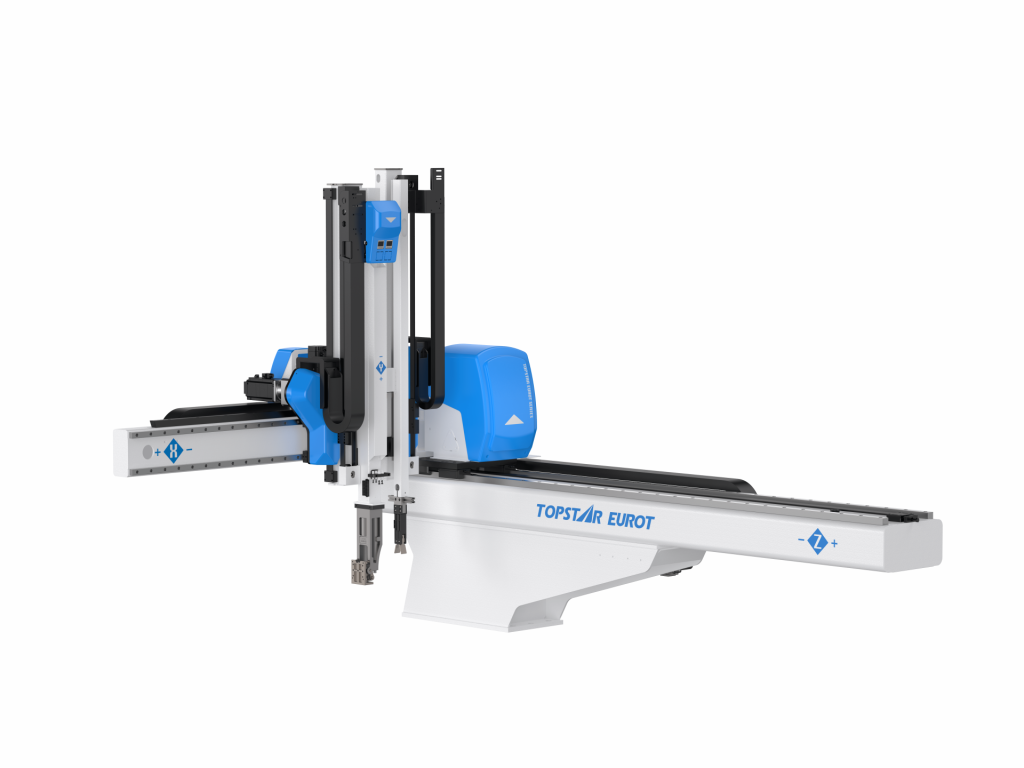

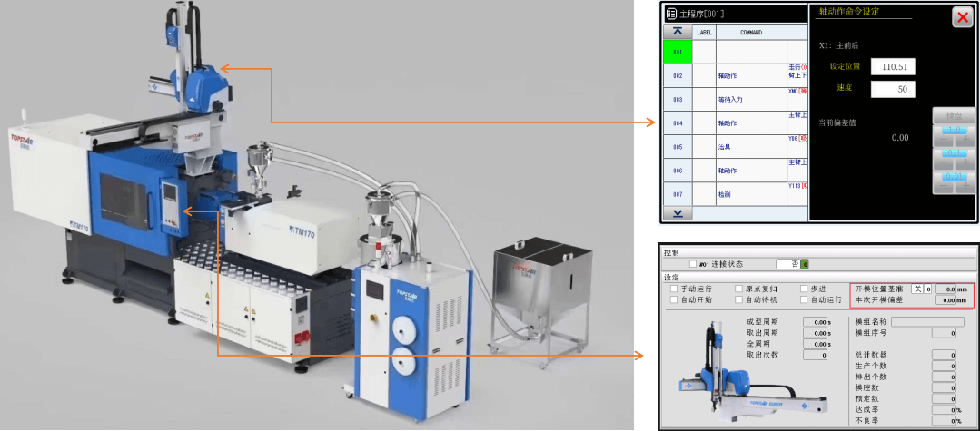

The new generation of injection molding robots achieves accurate, energy-saving, and intelligent five-in-one servo drive in terms of technology and efficiency. To solve the cost of each stop and collision, one servo driver can directly control 5 servo motors, making the removal control more precise. At the same time, the energy efficiency is increased by 20% through the multi-axis common bus design. The arm is made of lightweight aluminum alloy, reducing weight by 20%. It also uses high-rigidity precision slide rails and high-strength steel belt transmission to make high-speed operation less noisy and have a longer life.

Device interconnection

They realize cross-system interconnection through network protocols, which suffer from factors such as signal delay, poor compatibility, and low stability. However, the new generation of injection molding robots supports the Modbus RTU communication protocol. Through the open architecture of the underlying control system, the auxiliary machines and injection molding machines around the injection molding machine have a native language for system integration, making equipment interconnection an extension of the system. By supporting host call signals, you can achieve integrated operations and improve the efficiency of the production line. It solves problems such as failure to remove an equipment alarm caused by ejection position deviation and uncoordinated suction time.

Break through traditional limitations

While traditional injection molding robots meet many manufacturing needs, their shortcomings have become increasingly apparent with modern production demands and developments. We need more advanced solutions regarding flexibility, speed, and energy consumption. Therefore, a new generation emerged, and technological upgrades and updates brought more benefits.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/04/24

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/04/24

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/04/24

- Topstar Special | National Science and Technology Workers Day 2024/04/24

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC