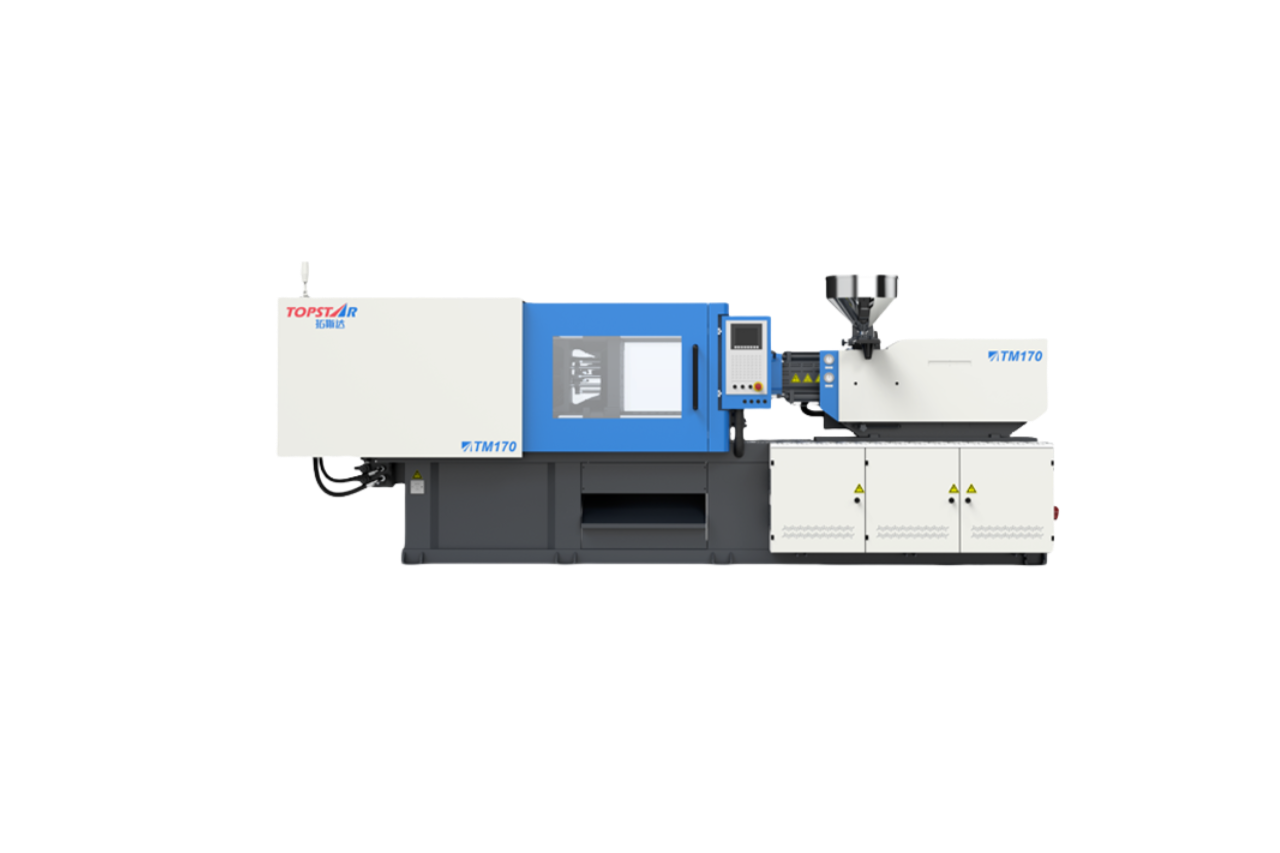

TMII Servo-Driven Injection Molding Machine(90T-470T)

2021/12/22 By Topstar

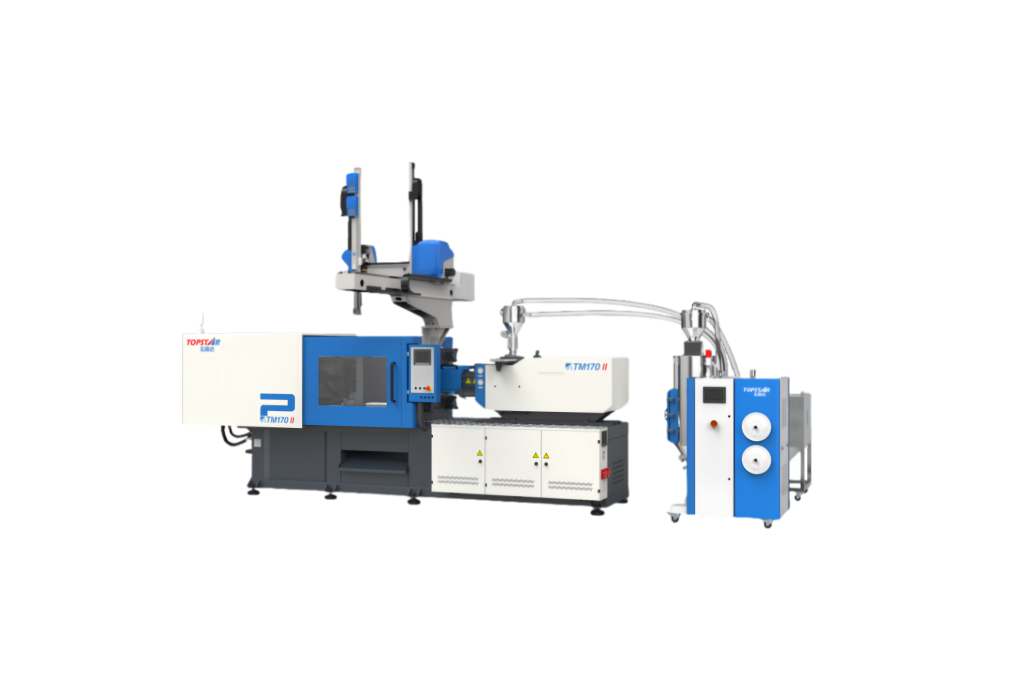

The TMII servo-driven injection molding machine (90T-470T) developed by Topstar represents a leap forward in intelligent injection molding technology. The injection molding machine combines servo drive technology with the “injection molding process integrated machine” concept. Based on open single-machine control can open up the overall control of the automated production line. According to the characteristics of injection molding, it can be divided into feeding automation, molding automation, removal automation, and whole-plant modularization to improve injection molding efficiency for customers.

Brand-new injection molding machine product concept

Investing in equipment and planning is a complex link. It is necessary to master the technology of various host machines and peripheral equipment from procurement to technology. Due to the wide range, one link often affects the overall efficiency. Therefore, we put forward the product concept of an “injection molding process integrated machine.” It will be implemented in three stages: system connection, hardware integration, and process innovation. By helping customers diagnose and configure a process-integrated system for customers, the system can be connected. If they are all single machines with open systems, achieving system connection is easier and faster. Therefore, in the second and third stages of research and development, we also jointly explore and design with specific industry customers for customers’ manufacturing processes.

What problems does the “injection molding process integrated machine” solve?

Through integrated control and process linkage, the process machine reduces the operator’s workload of fine-tuning and monitoring the main and auxiliary equipment, reduces labor costs, and improves production efficiency. After use, one operator can monitor and fine-tune multiple devices, reducing the labor input of multiple devices. Secondly, the process machine realizes the synchronous linkage of the manipulator and the mold opening process, shortens the molding cycle, and improves production efficiency through the early arrival and precision compensation functions. It enables the manipulator to grasp the product more quickly and accurately, reduces the number of abnormal alarms and equipment maintenance, and further improves production efficiency. At the same time, they adopt an open system, which provides space for expanding and upgrading equipment, makes management easier, and realizes informatization.

Upgrade of the hardware part of the injection molding machine

Based on the concept of an “injection molding process integrated machine,” Topstar upgraded the mold adjustment structure of the TMII servo-driven injection molding machine to achieve automatic and precise mold adjustment with one button. The mold can be accurately and in real-time position during setup. The integrated system uses feedback loops and high-precision sensors to automatically adjust the position of the mold according to user-defined specifications. This ensures that the mold is always in the optimal position during the injection molding, greatly reducing setup time and eliminating human errors in mold alignment. As a result, manufacturers can significantly increase production while maintaining the highest accuracy and part consistency throughout the production cycle. In addition, automatic precision mold adjustment allows for quick replacement of different molds, minimizing machine downtime during production switchovers.

Comprehensive upgrade of the oil system

One of the main improvements in the upgraded oil system of the TMII servo-driven injection molding machine is its enhanced safety features. Topstar uses advanced filtration technology to effectively remove impurities from the oil, preventing them from damaging sensitive machine parts. At the same time, the upgraded filtration system uses multi-stage filters and high-efficiency filter materials to provide excellent protection against contaminants and reduce the risk of system failure due to oil deterioration or clogging.

In addition to better filtration, the team has optimized the oil system for greater stability. Adding a high-performance oil pump improves pressure consistency throughout the system, ensuring that each component always receives the proper pressure and lubrication. This enhanced pressure control reduces the risk of uneven mold filling, thereby avoiding defects or inconsistencies in the final product.

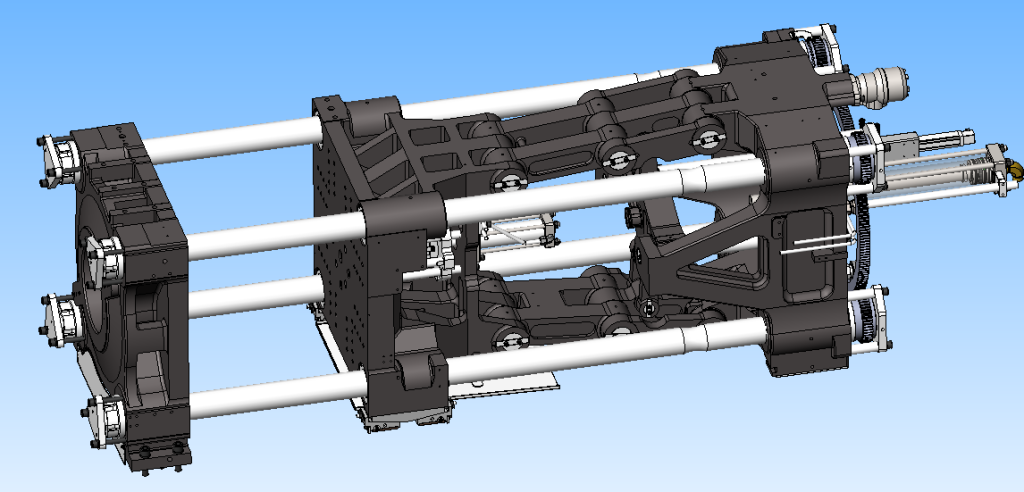

New oblique hinge layout

The new oblique hinge layout optimizes the force distribution during mold opening and closing, which can reduce the stress on the mold, resulting in smoother and more uniform movement. In addition, the system now achieves mold opening position accuracy of less than ±1mm, ensuring that you perfectly align the mold every time, even after long cycles or high production. This level of precision is critical for manufacturers who need consistent, high-quality parts with tight tolerances. In addition to high precision, the mold opening process is characterized by fast and stable template movement. The oblique hinge layout enables fast mold opening and closing speeds, which is critical for high-speed production lines that require fast cycle times without sacrificing quality.

Make injection molding more intelligent and digital.

The “injection molding process integrated machine” control and automation functions release the difficulty of operation. More efficient personnel input and less manual debugging time mean enterprises can reasonably plan and allocate human resources and improve labor utilization. The application of TMII servo-driven injection molding machines meets customers’ needs for development, transformation, and upgrading in digitalization, intelligence, and automation.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2021/12/22

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2021/12/22

- Star Case | Topstar helps Santong upgrade its intelligent plant 2021/12/22

- Topstar Special | National Science and Technology Workers Day 2021/12/22

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC