The wholesale of injection molding machines helps companies save costs

2024/02/18 By Topstar

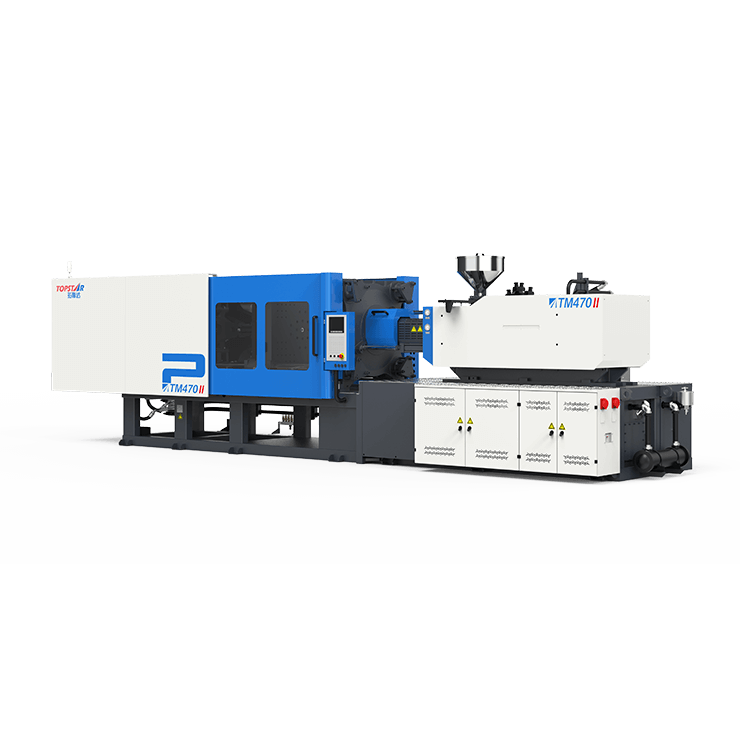

In the highly competitive injection molding manufacturing market, the cost of injection molding machine equipment is the first factor that any company must consider. One of the ways that companies often explore to reduce costs is to Wholesale of injection molding machines. In this comprehensive guide, we’ll explain how wholesaling injection molding machines can help companies save costs while exploring the many benefits wholesale sourcing brings to businesses across various industries.

Reduce costs with the Wholesale of injection molding machines

This approach can bring significant economic benefits, reduce overall costs, and improve manufacturing operation efficiency. As an injection molding machine manufacturer, we often offer discounts or special prices for bulk orders, allowing businesses to purchase injection molding machines at a lower price than they would get if they bought them individually. This reduction in upfront investment allows the company to allocate resources more efficiently and reinvest the savings into other areas of its operations. Additionally, they can bring economies of scale. By purchasing multiple machines simultaneously, businesses can streamline production processes, increase output, and achieve higher levels of efficiency. This scalability enables manufacturers to meet growing demand without disproportionately increasing costs.

Improve efficiency with Wholesale of injection molding machines

One of the main advantages of streamlining supply chain operations through Wholesale of injection molding machines is increased efficiency. Businesses can streamline their procurement processes, reduce administrative overhead, and minimize the time and resources required to process and manage orders. This efficiency gains traction throughout the supply chain, from procurement to production, helping to improve overall operational efficiency. At the same time, enterprises can better predict their equipment needs and maintain sufficient inventory levels to meet production needs, reducing the risk of out-of-stocks, minimizing delivery times, and improving production planning and scheduling, thus making operations smoother and improving customer satisfaction.

Value Proposition of Wholesale of injection molding machines

This approach does not mean sacrificing quality for cost savings. Many suppliers can offer the best quality injection molding machines at competitive prices, allowing businesses to get high-quality equipment without spending a lot. At the same time, wholesale purchasing of injection molding machines improves supply chain efficiency and reduces logistics complexity. Consolidating orders into a single transaction streamlines the purchasing process, reduces administrative overhead, and minimizes shipping and handling costs associated with multiple smaller shipments. This simplified procurement approach improves operational efficiency and lowers the total cost of ownership of injection molding machinery.

Reduce risk and uncertainty

The Wholesale of injection molding machines has clear advantages in risk management and reducing corporate uncertainty. By purchasing multiple machines in one transaction, businesses can spread their investment across a broader range of assets, reducing the risk of individual equipment failure or performance issues. This approach helps reduce the risk of downtime and production interruptions due to unforeseen equipment failures, ensuring continuity of operations and maintaining business continuity. This proactive approach to risk management enhances business resiliency and continuity and protects against potential business disruptions. Additionally, a wholesale approach protects companies from equipment costs or availability fluctuations by locking in prices and ensuring inventory in advance. Reduced risk of delays and cost overruns.

Maximize ROI

Achieving maximum ROI from Wholesale of injection molding machines involves strategic planning and leveraging various factors to optimize the financial results of your investment. An essential aspect of maximizing ROI is cost optimization. This approach allows companies to purchase injection molding machines at a discount, reducing unit costs compared to buying them individually. Through targeted planning and execution of wholesale purchases, companies can realize significant cost savings over the life cycle of equipment. Whether through reduced procurement costs, economies of scale, or streamlined operating expenses, this approach helps improve overall ROI in every aspect.

Unleash competitive advantage

This is an excellent approach for companies looking to save costs and become more competitive. Businesses can achieve significant cost savings without compromising quality or performance by leveraging the economics of bulk purchasing, streamlining supply chain operations, and obtaining high-quality equipment at competitive prices.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/02/18

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/02/18

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/02/18

- Topstar Special | National Science and Technology Workers Day 2024/02/18

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC