The role of the desktop injection molding machine in rapid prototyping

2023/11/27 By Topstar

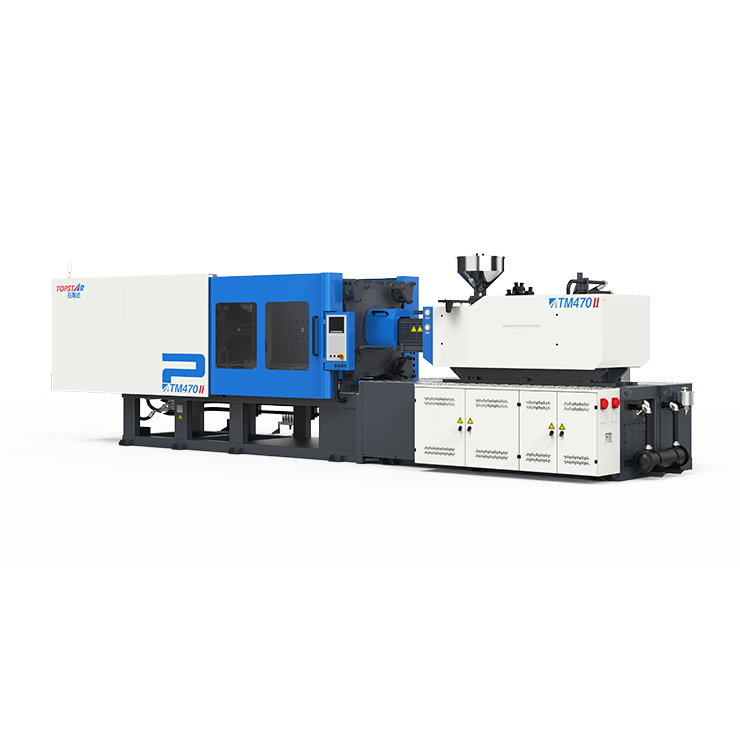

Rapid prototyping is essential for innovation in the dynamic landscape of product development. They integrate advanced technology into the design and manufacturing process, with desktop injection molding machines becoming one of the key players, reshaping traditional boundaries of prototyping timelines and functionality. In this guide, we look in-depth at the critical role of desktop injection molding machine in rapid prototyping, uncovering their complexities and revealing their potential for designers, engineers, and manufacturers alike.

Unleashing the Advantages of Desktop Injection Molding Machine

desktop injection molding machines take rapid prototyping to a new level of precision. The inherent ability to create complex and detailed prototypes sets these machines apart, meeting the growing need for accuracy in product development. The seamless integration of digital design and desktop injection molding speeds up the iteration process, allowing the design team to respond to feedback and make real-time adjustments quickly. Such iterative cycles increase the prototyping phase’s efficiency and foster a dynamic and collaborative environment. Designers and engineers can soon modify molds, adjust parameters, and iterate continuously without extensive delays.

The Economic Advantages of Desktop injection molding machine for Prototyping

Cost considerations often have a significant impact on the choice of prototyping method. The economic advantages extend beyond direct cost savings. Desktop injection molding machines offer innovators a way to test and refine their concepts without committing to mass production. This ability to iterate and cost-effectively fine-tune designs enhances overall project viability. The reduction in material waste and the ability to create multiple prototypes from a single mold result in economic advantages that resonate across industries. Efficient use of resources and streamlined processes not only comply with budget constraints but also emphasize the sustainability of desktop injection molding as the first choice for cost-conscious innovators.

Expand Prototyping with Desktop Injection Molding Machines

Material diversity is a hallmark of desktop injection molding machines and dramatically affects the breadth of rapid prototyping applications. Adaptability to a wide range of materials makes tabletop injection molding a universal solution for industries with different requirements. From engineering-grade resins to bio-based polymers, the material palette enables prototype designers to align their designs with specific industry standards and regulations. This adaptability ensures that the prototype accurately represents the final product and can be tested under conditions that reflect the intended real-world application. Designers can also explore options before committing to volume production, ensuring the final product meets expected specifications. Whether testing different thermoplastics, experimenting with specialty materials, or simulating real-world conditions, the flexibility provided by desktop injection molding machines helps achieve precise prototyping goals.

Seamless transition to desktop injection molding machines

Beyond the prototyping stage, the journey of a product from conceptualization to mass production is a critical transition. The scalability of desktop injection molding machines not only speeds up time to market but also minimizes the possibility of design changes during evolution. By maintaining the integrity of the initial prototype, innovators can confidently proceed to mass production without encountering unforeseen challenges. A seamless transition ensures prototype designs go directly to manufacturing, increasing overall project efficiency and reducing the potential for costly modifications.

Automation advances

Significant advances in automation will drive the continued development of desktop injection molding machines. Desktop injection molding automation significantly contributes to process optimization and efficiency. They can be seamlessly integrated into workflows, handling tasks such as mold loading, part disassembly, and quality inspection. Not only does this reduce the need for manual labor, but it also increases accuracy and repeatability, ensuring that prototypes are always of high quality. The role of automation in desktop injection molding is becoming increasingly integral as the industry moves toward unattended manufacturing, where operations can continue without human intervention.

In general

The transformative potential of desktop injection molding machines in rapid prototyping promises to further revolutionize the industry, inspiring innovators to embrace these advancements and leverage them into groundbreaking prototyping solutions. You can also view more information about injection molding machines on our official website. You are welcome to go and learn more.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/11/27

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/11/27

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/11/27

- Topstar Special | National Science and Technology Workers Day 2023/11/27

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC