The new-generation mold temperature controller that meets customer needs

2024/09/27 By Topstar

As one of the main components of auxiliary equipment in injection molding, the mold temperature controller has global sales of US$520 million in 2023, accounting for about 32% of the entire auxiliary equipment market, according to the “In-depth Research and Future Trend Analysis Report on the Development of Global and Chinese Injection Molding Machine Auxiliary Equipment Industry from 2023 to 2029”. As essential auxiliary equipment, fast heating, stable temperature, and no leakage are its standard functions. In order to meet the needs of industry customers for intelligent and digital upgrades, solve the temperature control problems of injection molding production, and improve product yield, Topstar’s newly launched 4th-generation mold temperature controller is constantly evolving for precision injection molding functions.

We have collected the problems encountered by customers in production and shared them with our customers to discuss the performance and advantages of the 4th-generation mold temperature controller in practical applications.

Hardware precision of mold temperature controller

Problem 1 encountered by customers: poor water quality and pipe blockage affect the heating effect

Due to the high concentration of calcium and magnesium ions in the water, it is easy to block the water pipe. To solve this problem, the water quality must be purified.

To solve this problem, Topstar upgraded the water temperature machine with a copper heater, which makes the impurities in the water less likely to adhere to the copper surface and not easy to scale. This makes the copper material ductile and superior in thermal conductivity, increasing the life by 40% and the efficiency by 10%. You can commonly use the mold temperature machine even with poor water quality.

In addition, Topstar comes standard with a 50-mesh high-precision filter and an optional 30μm filtration grade precision filter. The filter aperture is about 0.03mm, which is equivalent to the diameter of a hair, and can effectively filter impurities to prevent mold clogging.

At the same time, we have also added a liquid-level detection function using a Teflon float (the float has a zero welding process, and there is no welding leakage problem). You can use this for pure water and various poor water qualities, such as oil and iron filings.

Problem 2 encountered by customers: Unstable water pressure, low water inlet pressure, affecting the yield rate

Water inlet pressure is crucial for precise temperature control. If the water pressure is insufficient, it is easy to dry-burn the pipeline. You can replace the water supply equipment or switch to other mold temperature machines.

For this problem, Topstar uses water pressure adaptive temperature regulation. The 120℃ standard water-type mold temperature controller includes a pressure detector, ensuring detection accuracy reaches 1%. You can adjust the upper limit of the operating temperature based on different water inlet pressures to maintain regular use of the mold temperature controller when the water inlet pressure is low.

The 160℃ and 180℃ mold temperature controllers use an indirect cooling sealed circulation mode and micro-boosting pump water replenishment to lower the water inlet pressure requirements. People commonly use them when the water inlet pressure exceeds 0.3 bar.

Problem 3 encountered by customers: Components such as water pumps, pipes, and solenoid valves are easily damaged

In the daily operation of the mold temperature controller, metal pipe parts will experience continuous heating and cooling cycles. This repeated temperature change can easily cause metal fatigue, resulting in structural damage to the pipe parts.

The Topstar high-temperature water-type mold temperature controller is equipped with a standard gas collecting tank, which can absorb the additional pressure caused by this expansion and contraction, effectively buffer the pressure fluctuations inside the system, and thus prevent component damage caused by pressure changes. At the same time, the gas dissolved in the water will be released. The space provided by the gas collecting tank can collect these gases to prevent them from flowing back into the system, reduce the formation of bubbles, and ensure stable operation of the equipment performance.

Intelligent system of mold temperature controller

Problem 4 encountered by customers: Inaccurate temperature control and low product yield

The large temperature fluctuation is due to the fact that the mold temperature machine’s temperature control accuracy cannot meet the actual production requirements, and a more accurate device is needed for temperature control.

First, we upgraded the software and hardware to make the temperature control more accurate. The accuracy of the Topstar 4th generation mold temperature machine is ±0.1℃. The latest PID temperature control algorithm improves temperature control efficiency by 10%, ensuring uniform temperature. At the same time, the hardware adopts solid-state relay temperature control with a response time of 0.1 seconds. With the dual protection of software and hardware, the system temperature fluctuation is controlled within ±0.1℃, ensuring high product yield.

In addition, the more advanced mold temperature controller includes 1MHz ultrasonic flow monitoring. This monitors the media flow in real time, can detect bubbles larger than 2mm, ensures that the water flow is liquid, and makes the temperature control stable and accurate.

It is also standard to use a gas-liquid separation device, which can quickly separate the gas in the medium to prevent uneven heating of the mold. These functions can prevent mold temperature fluctuations and reduce the defective rate by about 3%~5%.

Application Industry

Topstar’s 320℃ oil-type mold temperature controller for the die-casting industry has the characteristics of precise temperature control of the 4th-generation machine, rapid heating and cooling, and easy maintenance and operation. At the same time, to ensure safe use, we adopt an electrical box separation design to isolate the high-temperature conduction in the chassis and effectively protect the electrical components. In addition, the magnetic drive pump we use solves the problem of natural wear and leakage of the shaft seal. An over-temperature protection switch is standard on the motor coil to prevent overheating and burning, lower the failure rate, and reduce the risk of accidental touch.

The 120℃ mold temperature controller for the automotive industry uses a cooling solenoid valve with a diameter of 20mm. This valve has a faster cooling speed and a lower temperature control temperature and is more suitable for the temperature control of thick-walled products in the automotive industry.

Explore the value of the diverse applications of mold temperature controller

From the first to the fourth generation of mold temperature controllers, Topstar has achieved many breakthroughs in their research and development, including gas-liquid separation structures and fluid inlet and outlet connection devices.

Through the integration of hardware and software, and combined with the diverse application experience of 15,000 customers, the mold temperature controller can adapt to a broader range of working conditions, allowing auxiliary equipment and customer manufacturing to move towards intelligent upgrading.

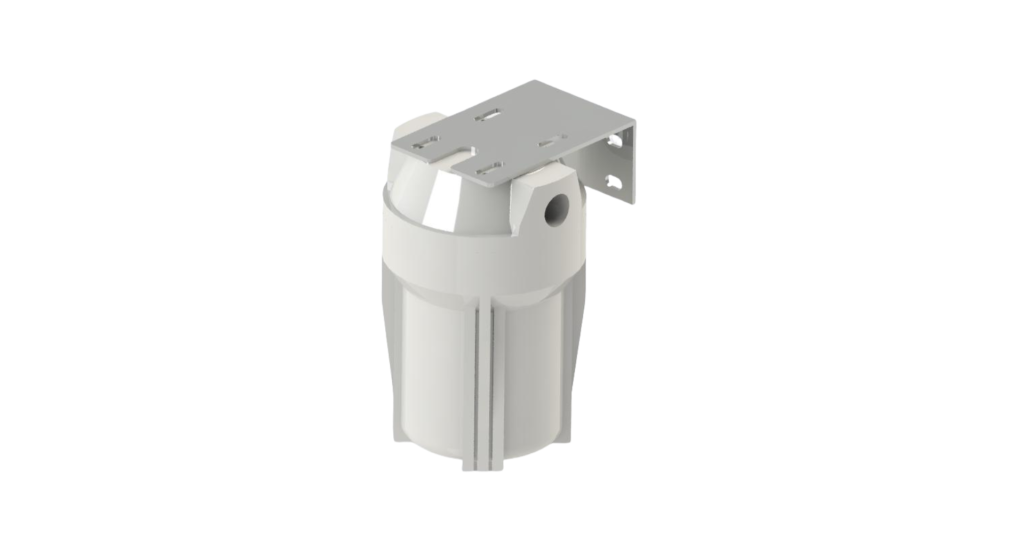

Topstar’s 4th-generation mold temperature controller currently includes a water-type mold temperature controller (120℃-180℃), an oil-type mold temperature controller (200℃-320℃), heating power 8-36KW, water pump power 1-5HP, and single-stage and double-stage temperature control series to choose from, to meet customers’ different working conditions.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/09/27

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/09/27

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/09/27

- Topstar Special | National Science and Technology Workers Day 2024/09/27

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC