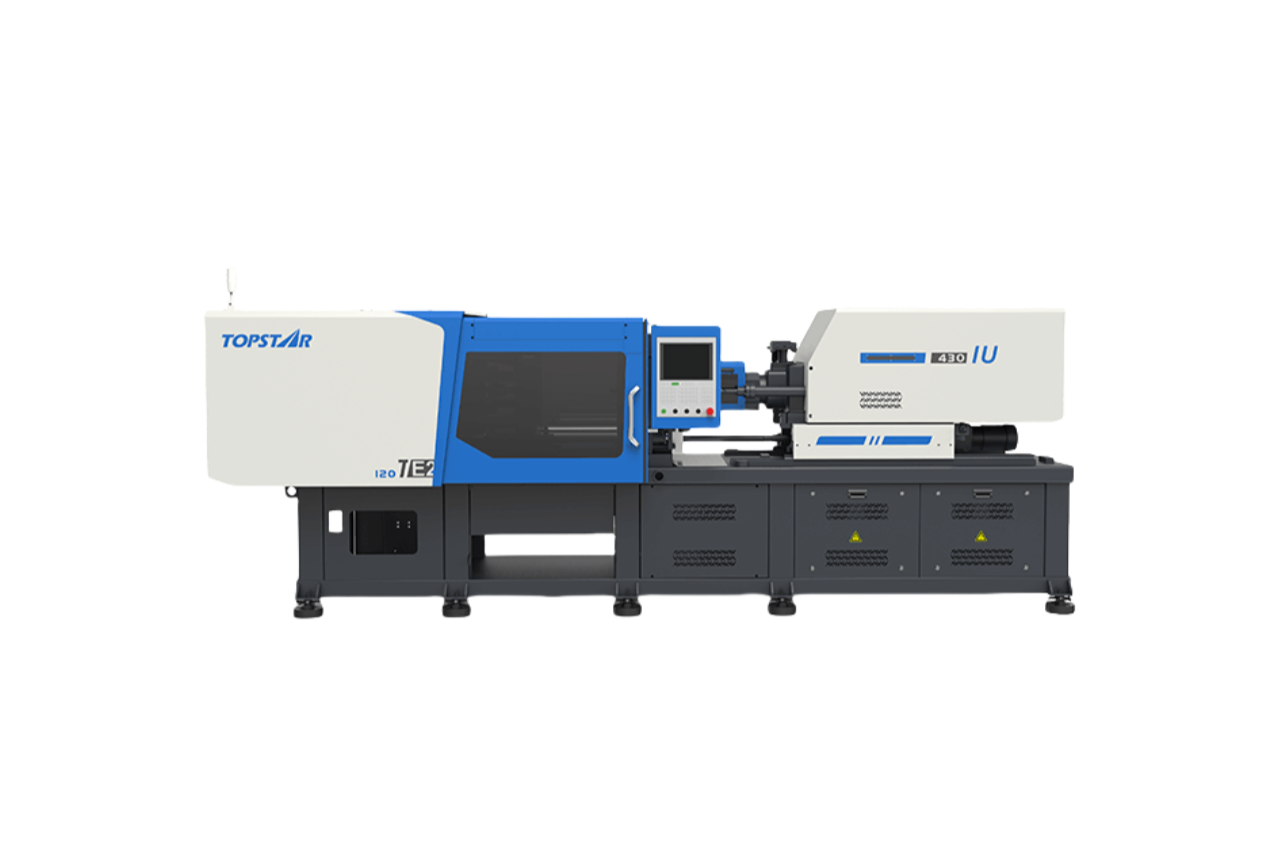

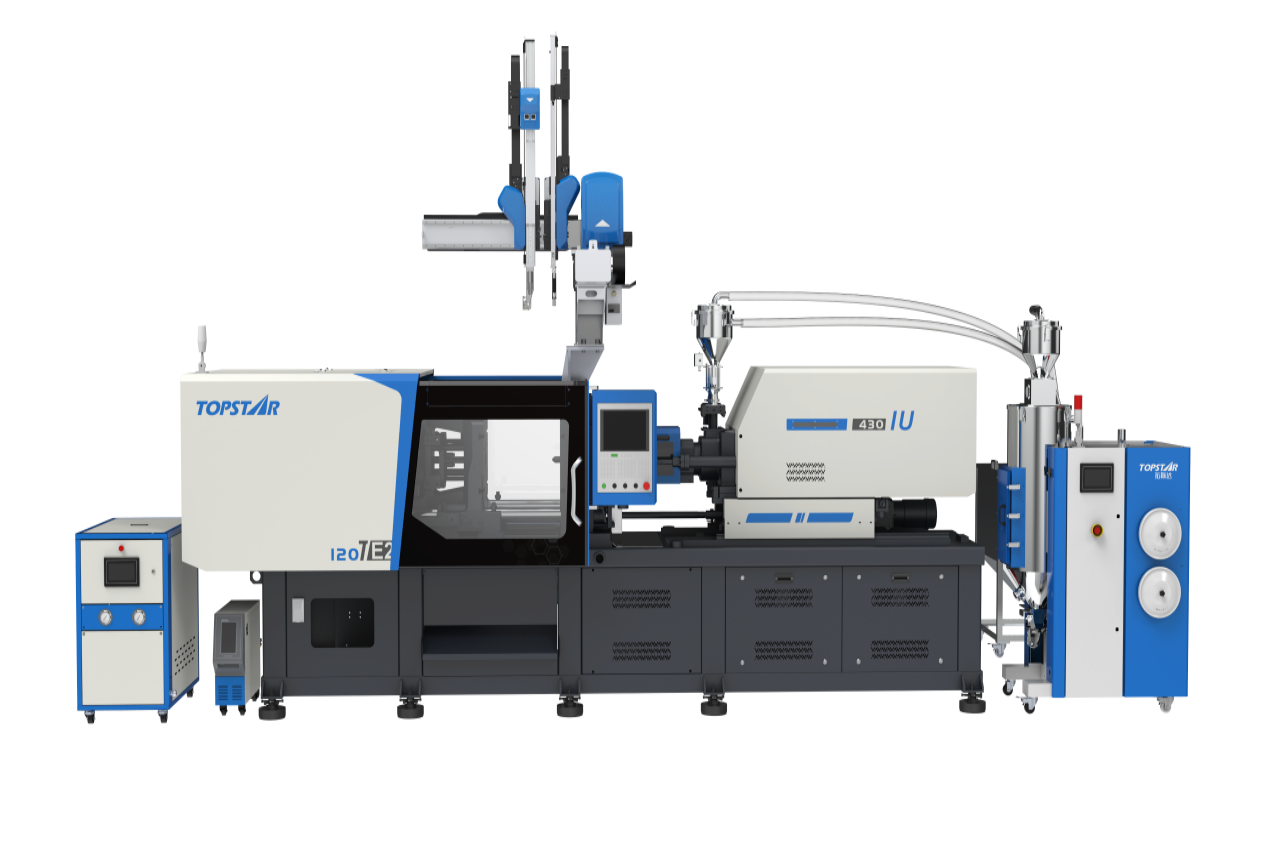

Intelligent manufacturing is the development trend of the manufacturing industry, and the cornerstone of Topstar’s smart manufacturing strategy is the concept of open injection molding machine control systems. Traditional injection molding machine usually operate as isolated units with limited interaction between components and minimal flexibility in adapting to different production requirements. At Topstar, we have… Continue reading How to use Topstar injection molding machine to realize smart manufacturing technology?

How to use Topstar injection molding machine to realize smart manufacturing technology?