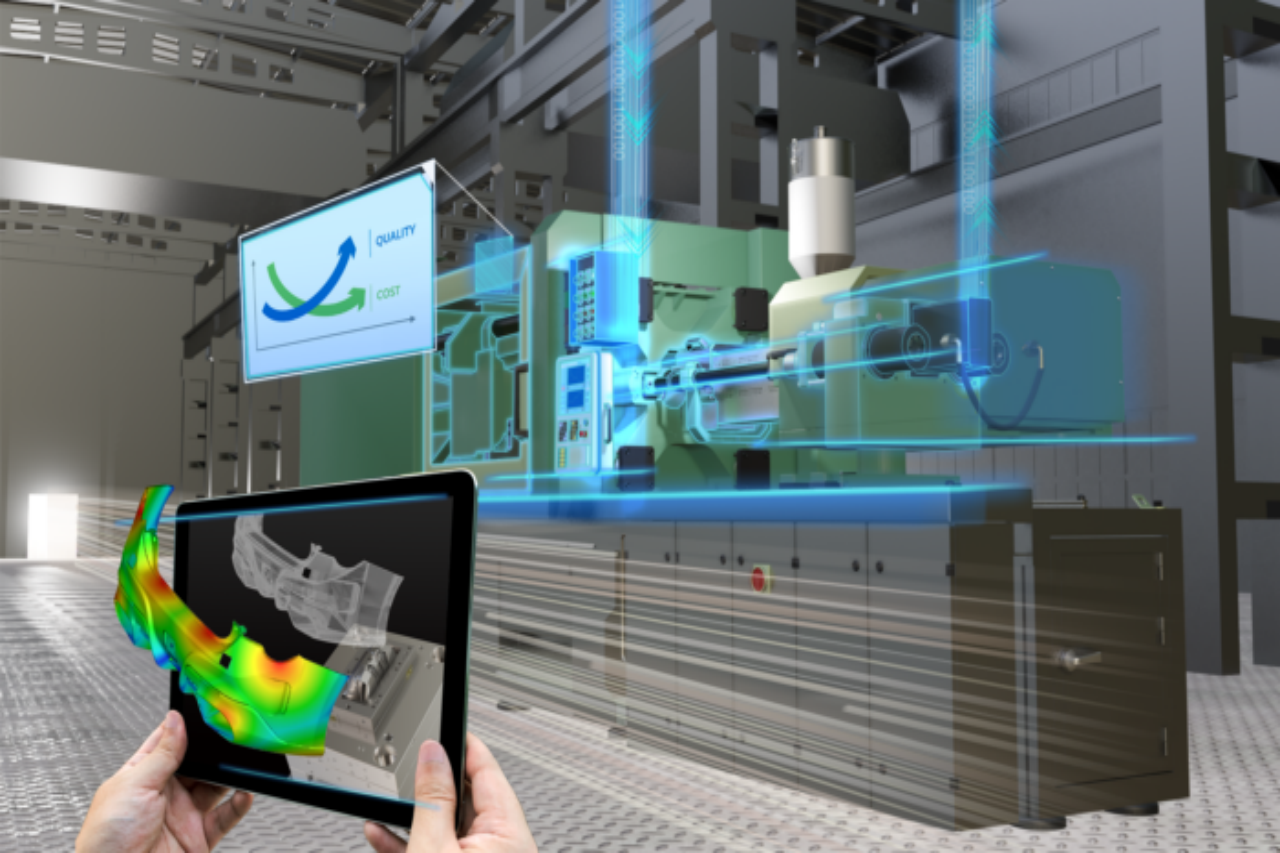

Manufacturers across many regions lose 15% to 20% of their production time due to communication delays and parameter loss in traditional hydraulic or basic electric injection molding machines. For a 24/7 factory, this translates to 1,080 hours of wasted production annually and millions of dollars in lost revenue. Even worse, 4% to 8% of parts… Continue reading Digital Platform All Electric Injection Molding Machine: Enhance Efficiency & Parameter Control

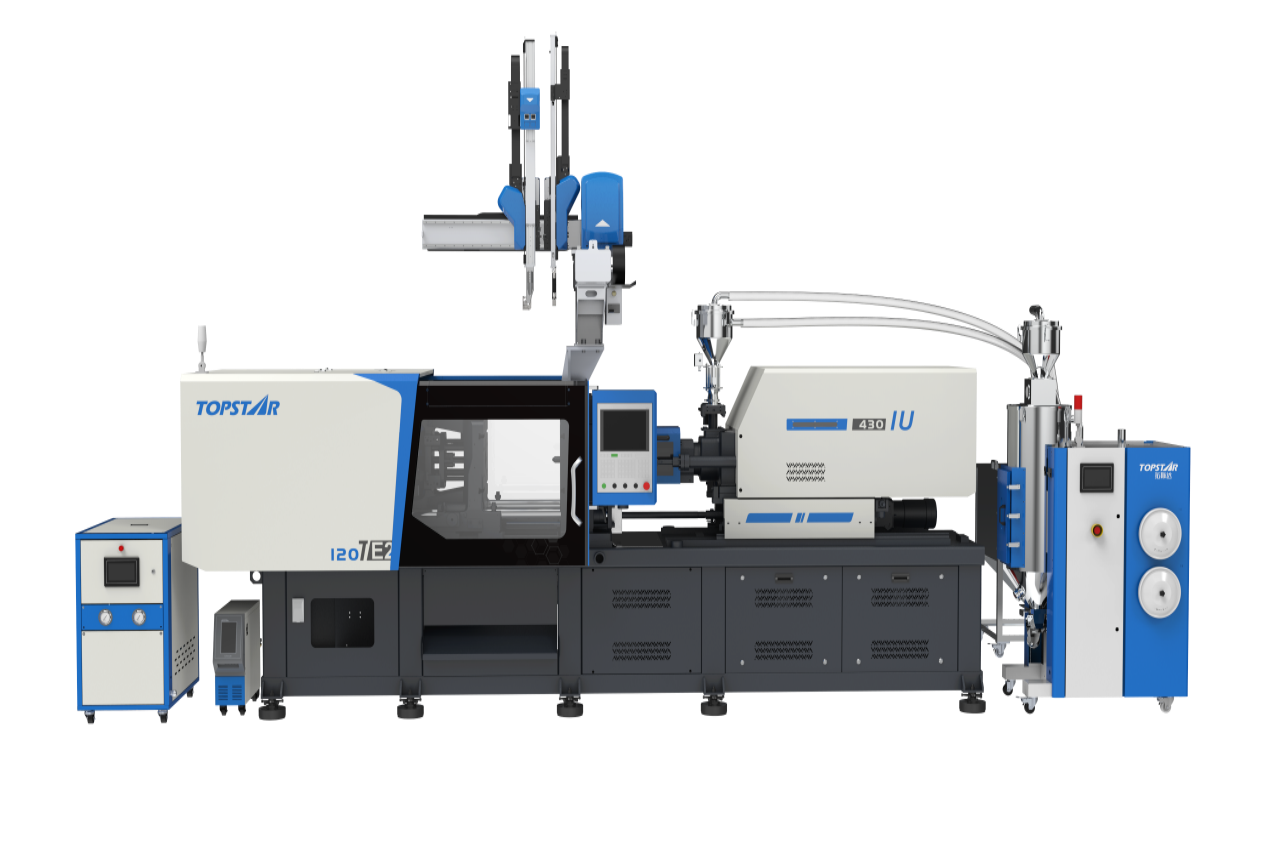

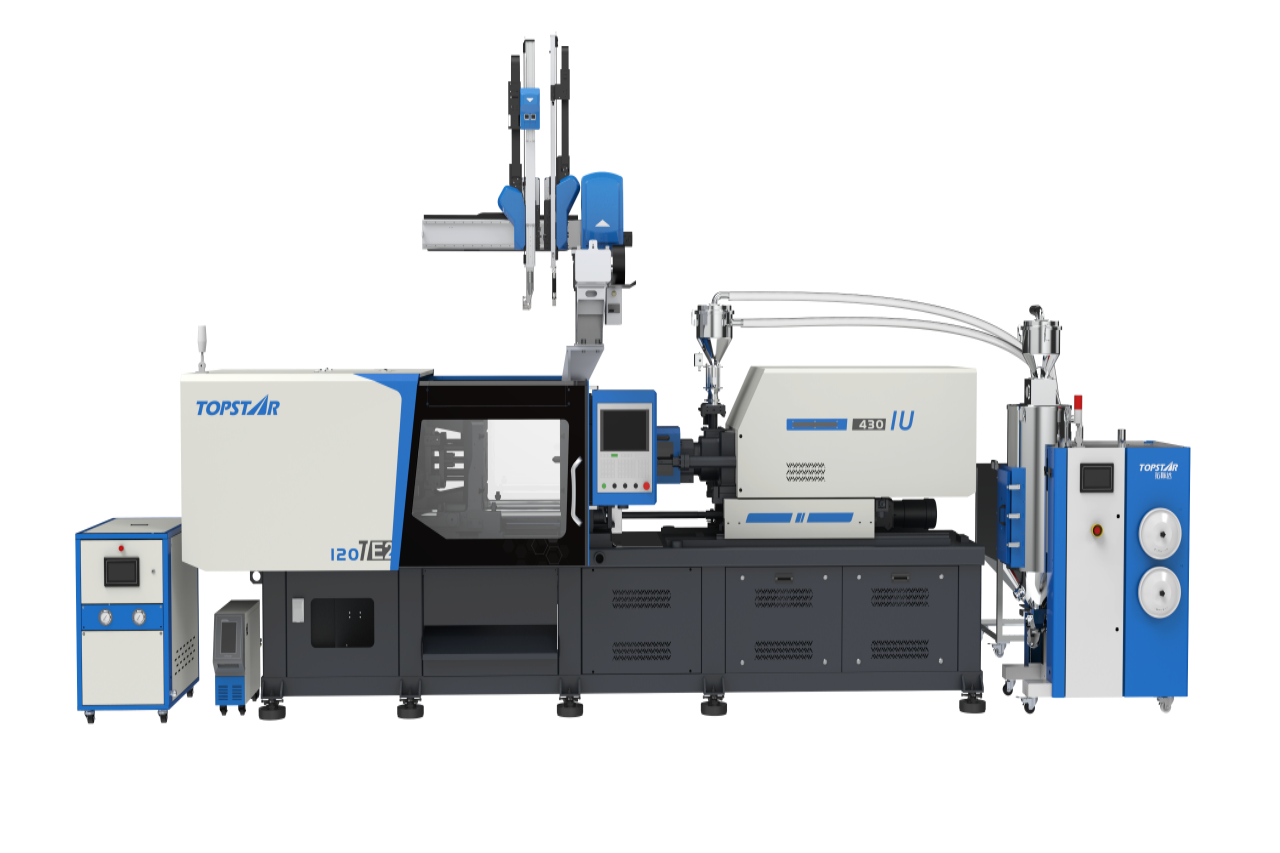

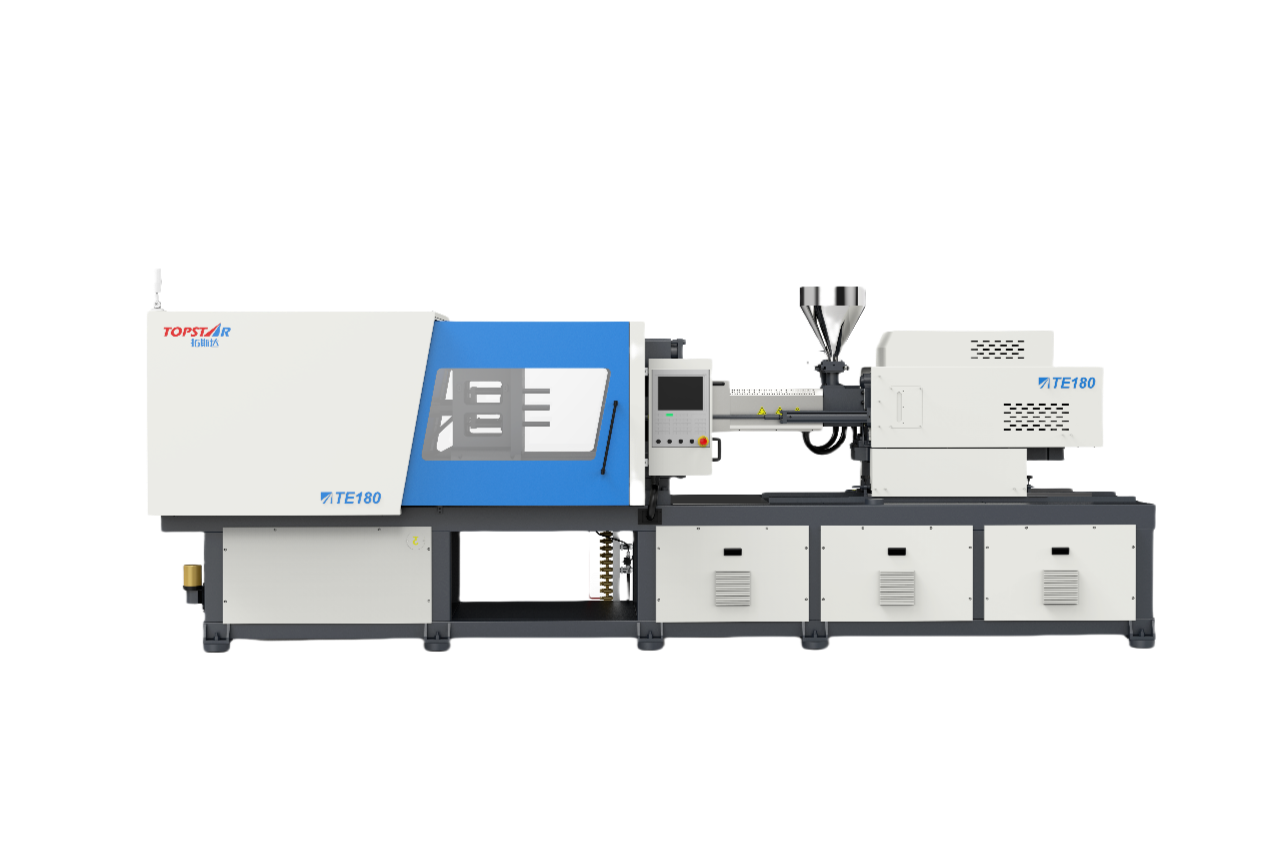

Digital Platform All Electric Injection Molding Machine: Enhance Efficiency & Parameter Control