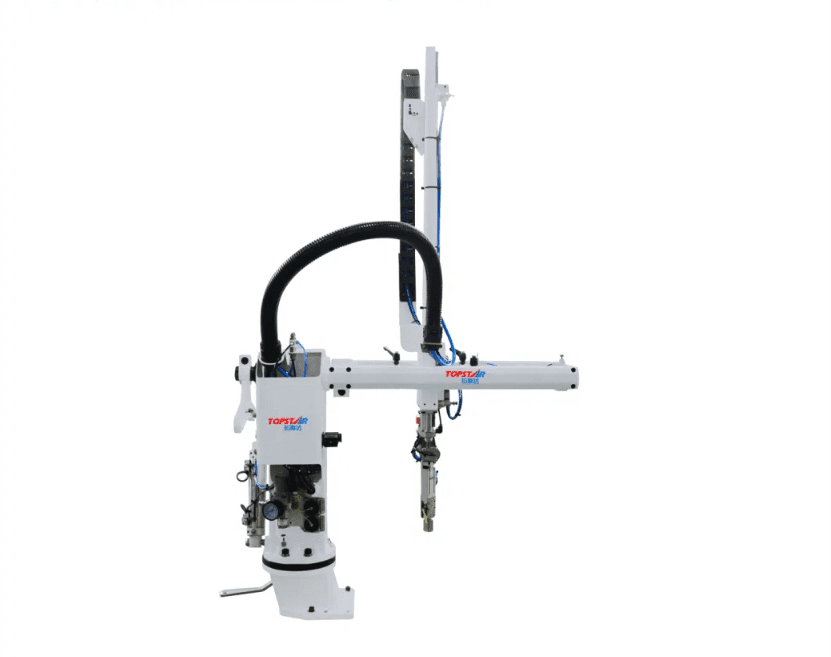

Swing Arm Robot: An Efficient Option for Your Industrial Automation

2023/08/23 By Topstar

In today’s high-tech life, our automation is particularly efficient in various fields, especially manufacturing. The swing arm robot is one of those robots, a highly versatile industrial automation solution that can help you increase productivity and reduce costs in your manufacturing process. Many friends already know their existence, but we still take it out today to share and chat with you.

Use them to increase productivity while reducing costs and risks!

Swing arm robots are designed for industrial automation. They differ from other types of robots because they can locate areas that different kinds of robots cannot. They also require less space and power than traditional industrial automation equipment, making them ideal for small applications. These machines often pick up objects or move them on an assembly line. As such, they are usually found on assembly lines where heavy lifting is involved (such as automobile manufacturing). Because advances in sensor technology and computer vision algorithms allow these machines to operate safely alongside humans without causing harm or damage.

Can handle different parts, from small items to large components!

Swing arm robots can handle a variety of parts, from small items to large assemblies. They can flexibly solve problems that are difficult for other robotic systems. For example, if you need a rocker robot to pick and place various components of different sizes on an assembly line, a rocker robot might be right for you. Thanks to their unique design, these machines have greater flexibility than traditional industrial robots in handling tasks and positioning within the work area. They’re also less expensive than other options because they don’t require as much customization or setup time before being ready to use on the production line.

Swing arm robots offer flexible positioning capabilities and fast response times!

Swing arm robots offer flexible positioning capabilities and fast response times. These robots can move in all directions, making them ideal for applications that require frequent repositioning or movement between different points. They can also move quickly, allowing them to perform tasks at high speeds without sacrificing precision or accuracy.

Because swing arm robots have such a wide range of motion, they are more flexible than other industrial automation equipment. They can go to almost any part of the assembly line without changing their position first! Plus, since they don’t require as much space as other industrial automation equipment, it’s easier for companies that use swing arms on their production lines to find space for them within existing facilities.

Swing Arm Robots Can Move More Precisely Than Other Types of Robots!

Swing arm robots are unique in their ability to rotate in place, giving them a much more extensive range of motion than other industrial robots. They can move more precisely than different types of industrial automation because they have a fuller range of motion, allowing them to move closer to workpieces or handle more essential parts. They also allow you to perform tasks in tight spaces that traditional robots cannot.

In addition to these advantages over conventional systems, swing arm robots excel in assembly operations because they can reach all sides of an object without obstacles interfering with their motion path. This means less time spent repositioning tools or changing settings so everything lines up perfectly before moving on to the next step!

They are an innovative way for industrial automation to increase efficiency!

The swing arm robot is an innovative approach to increasing the efficiency of industrial automation. Their ability to move in multiple directions makes them ideal for many applications, including pick-and-place tasks and assembly line assembly.

Although other types of robots can also perform these functions, swing arm robots have several advantages over different kinds of machines:

They are more flexible than other robotic systems because they can quickly move between locations on a production line or a warehouse floor without manual reorientation by the operator. Swing arm robot are faster than most other industrial automation equipment because they do not require any assembly before use.

Human-machine integration is the trend of future industrial development

After reading the whole article, you can have a clearer understanding of the characteristics and convenience of swing arm robots in the industry. They are indispensable in many industrial manufacturing processes, thus reducing the disadvantages caused by labor. The combination of man and machine is a trend of future industrial development. People can significantly improve overall efficiency through the assistance of devices.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/08/23

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/08/23

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/08/23

- Topstar Special | National Science and Technology Workers Day 2023/08/23

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC