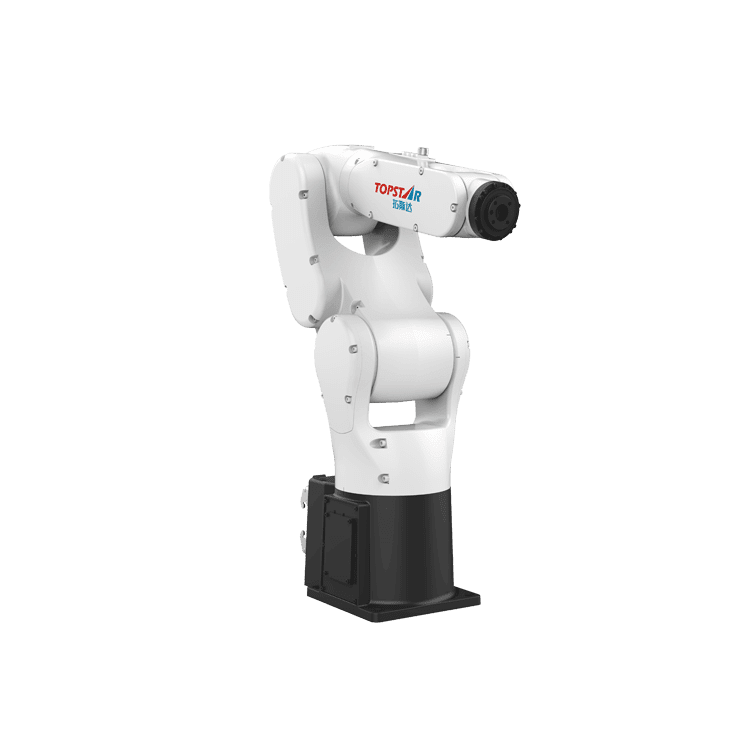

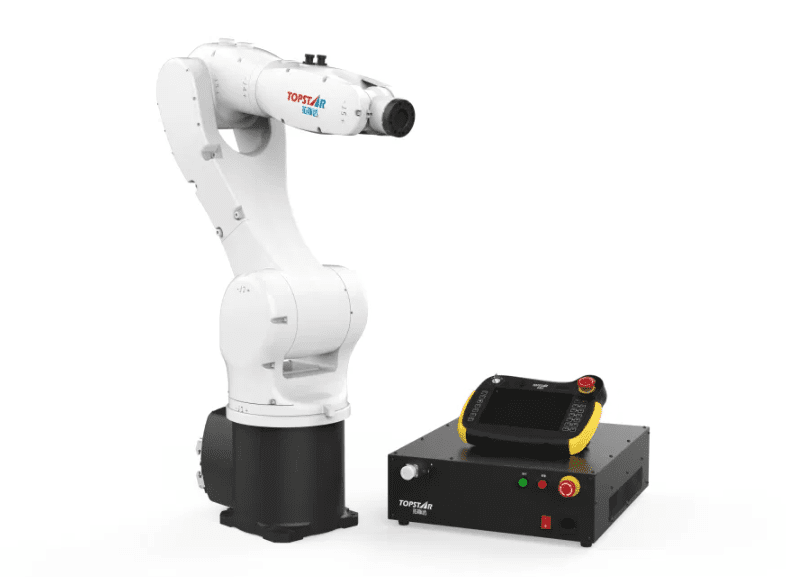

Six-Axis Industrial Robot Revolutionising Manufacturing Industry

2023/08/03 By Topstar

Industrial robots have existed for a certain period. With the development and reform of one revolution after another, we have created mobile robots. This is made possible by their product to allow them to perform tasks independently without human guidance. And the six-axis industrial robot we will share today is very suitable for enterprises that want to reduce costs by reducing workforce while increasing productivity levels. Today, more than 1 million of these industrial robots are in factories worldwide, slowly changing the entire manufacturing industry!

Six-axis industrial robot is a new generation of industrial robot!

Six-axis industrial robots are a new generation with six degrees of freedom. Traditional robots have only three degrees of freedom, so they can only move forward and backward, left and right, and up and down. Six-axis robots can perform tasks that conventional robots cannot because of their ability to rotate the wrist and move in different directions simultaneously. They are suitable for use in the automotive industry, manufacturing, and military applications where accuracy is critical to success!

They are suitable for part-finishing applications as well as assembly work!

Six-axis industrial robots are suitable for part-finishing applications as well as assembly work. They are ideal for applications requiring high precision and repeatability, such as the packaging of electronic components or manufacturing automotive components. The use of six-axis robots is also growing in medical devices, semiconductor manufacturing, and aerospace industries, where the need for high-quality products is critical. They can manipulate three dimensions with great flexibility and accuracy without requiring unique fixtures or tools. Through this feature, the completion rate on the production line is improved, and the occurrence of defective products is reduced.

Six-axis industrial robotics will become widely adopted in manufacturing over the next decade!

In the next decade, six-axis industrial robots will be widely adopted in manufacturing. Six axes allow these machines to move in any direction, making them more flexible. This enables them to handle various applications and tasks that would be too complex for conventional robots. They also offer increased safety compared to their predecessors: they are lighter, so there is no need for heavy safety guards around them; they have fewer moving parts, reducing the risk of injury or damage if something goes wrong; and They are designed with a low center of gravity.

Six-Axis Industrial Robots work alongside workers to improve productivity, quality, and safety!

Six-axis industrial robots are suitable for a variety of applications and industries. They are more flexible than other industrial robots, rather than having only three or four axes like the standard Cartesian coordinate system. This allows them to handle the movement of more material without additional tooling or support structures. They can achieve higher speeds than many other types of robotic systems while still maintaining accuracy and repeatability over time due to their ability to sense their surroundings through sensors such as laser scanners or touch probes, thus keeping track of their position relative to other objects. In addition, six-axis machines offer exceptional flexibility, allowing users complete freedom when designing specific, custom-made solutions.

They have revolutionized manufacturing in so many ways!

As you can see, the six-axis industrial machine has changed the manufacturing industry in many ways, and its flexibility has improved the slow efficiency of many enterprises. They can work in various positions and orientations, making them suitable for multiple applications. This makes them less expensive than standard six-axis robots and more accessible for customers to maintain. All these factors have prompted them to affect the manufacturing industry and accelerate the expansion and development of the manufacturing industry.

Eventually, we know.

In the future, we can see six-axis industrial robots covering more neighborhoods and industries, not just manufacturing. However, their impact on the manufacturing industry cannot be underestimated because they exist in almost all the factories around them. At the same time, more models will be available in our entire product system, and you will have more choices.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/08/03

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/08/03

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/08/03

- Topstar Special | National Science and Technology Workers Day 2023/08/03

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC