Servo Injection Robots Can Increase Productivity

2022/11/20 By Topstar

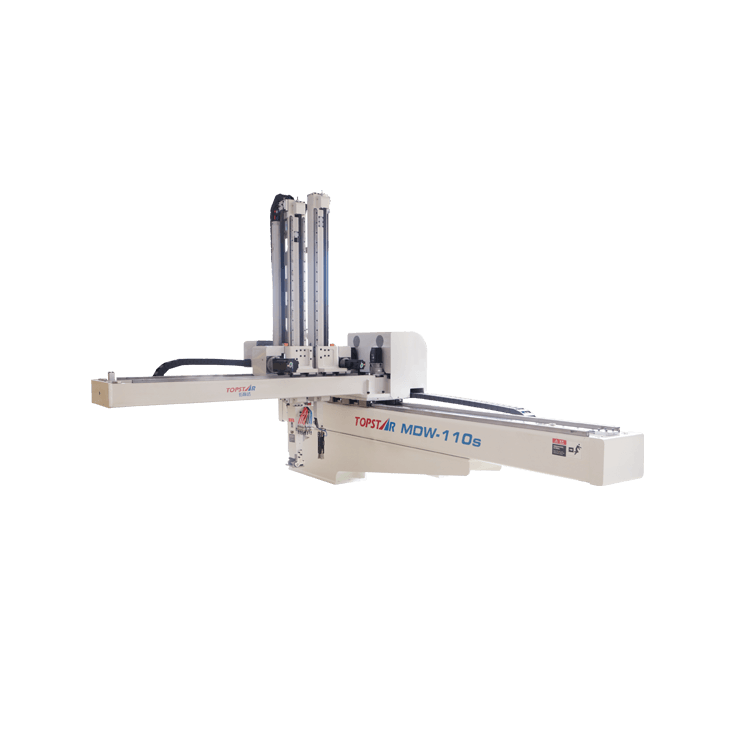

Servo Injection Robots Can Increase Productivity

For years, injection molding machines have been run by hydraulic systems. However, there is a new technology that allows for the use of servo drives on these machines. Compared with the hydraulic system, this technology has several advantages and more suitable mechanical types.

What is a Servo injection robot?

The servo drive is a motor controller with high-resolution position, velocity, and torque control. Unlike conventional endeavors, a servo drive can operate over various speeds and torques while offering precise positioning and force control. Servo motors are very efficient compared to other engines because they work at a constant rate regardless of load or application requirements.

Servo Injection Robots: What Makes Them Different from Swing Arm Robots?

The most significant difference between the swing arm robot and the servo injection robot is that the former uses a fork end actuator (FE), which is controlled by the operator using cylinders connected to both sides of FE’s FE’s k. For example, CNC-controlled linear actuators, commonly used with most modern servo injection machines, are connected directly to the mechanical linkage below them (rather than through the cylinder).

Move back and forth according to the command of their computer controller because they automatically perform tasks. Without any human interference, monitor the progress until completion. So workers can strengthen monitoring when needed, instead of letting people watch the machine all the time – because only one person needs to monitor, not two different people working together. Therefore, Better workflow management by reducing downtime between cycles. Thereby potentially saving costs. At the same time, the number of people performing tasks is reduced, which means that the risk is reduced so that the possibility of accidents occurring soon is less).

Several advantages of servo driver

Servo drives are a type of motor control system. Servo motors are exact and responsive, allowing the operator to make quick adjustments without worrying about the machine’s time. They also require less maintenance because hydraulic systems have fewer moving parts.

Servo drives are more efficient because they use less electricity than hydraulic systems, which means you can save money on your energy bills and reduce your carbon footprint simultaneously! Plus, servo drives don’t need any lubridon’tn or regular maintenance like hydraulic systems do, which saves you even more money in the long run!

Finally, Servo systems tend to last longer than other motors because they do not have too many moving parts. These components are not easily damaged because of the involvement of traditional methods.

It provides excellent energy conservation.

Servo drive technology is more energy efficient than traditional drives.

The servo drive system uses less energy than a standard motor/brake combination and, therefore, has an overall lower cost of operation.

Servo drives are more efficient than traditional motors in many ways.

They have higher power density, which means they can generate more torque per cubic inch of volume or pound weight. Leading to smaller motors that require less space and weigh less but still generate the same amount of torque as larger conventional motors. This makes them ideal for use in small areas where every inch and ounce counts, too!

Only one servo motor is required, decreasing the energy needed to run the machine.

You’re probably wondering what the big deal is about you. To understand why they’re so great, let’s compare them to hydraulic systems:

Servo motors let’s motor instead of two. This saves space and reduces energy consumption.

Servo motors are more efficient than hydraulic systems because they accelerate more. You can move your robot faster with less force (and, therefore, fewer pumps) than you would need with a traditional system.

Servo motors also offer more accuracy than hydraulics because they have zero backlashes. That means no lag in motion as the engine moves from position A to B (or back again).

Faster response time, higher acceleration and deceleration, and higher accuracy

Compared with a hydraulic system, a servo drive allows faster response time. Higher acceleration and deceleration, and higher accuracy. It also eliminates the need for external pumps and reduces maintenance and repair costs. The servo motor is independent in its housing, so all components are protected. It is not affected by dust or moisture, which will lead to corrosion over time.

This means that in a harsh industrial environment, for example, on oil drilling platforms or construction sites. When buildings are built with wood (such as plywood), there may be water in cold months, which means it will last longer than the motor. After processing, cut 2 “x 4” sections of wood. Laser measurements at 2 ‘x 4’ intervals using a wall-mounted laser line laser. It will fill every room, so when the workers come back later. They don’t know how much time has passed since they left earlier today – which is reasonable. Because according to science, everything is faster than light except photons. But even so, their speed will also slow down because of the friction between photon surfaces.

Less maintenance, higher energy consumption, and longer equipment life

Servo injection robots are more accurate than hydraulic systems, making them less prone to failure and downtime. They also increase speed and responsiveness compared to hydraulic systems. Servo drive allows for higher acceleration and deceleration, which helps to reduce maintenance costs.

As stated above, servomotors are more responsive than standard motors because they have no physical connection between their systems’ motor shaft and load-bearing parts (e.g., pump pistons). This means that any time there is a change in the position of either part of this system, there will be no lag between when one part moves relative to another. Therefore, these drives respond immediately!

Many manufacturers are seeking to upgrade their machines with this technology

Servo drives are a relatively new technology in the injection molding industry. Many manufacturers are looking to upgrade their devices with this technology, as it can help them increase productivity and improve quality control. The benefits of upgrading your machine include the following:

-Better energy savings

-Faster response time

-Higher acceleration and deceleration

-Greater accuracy

The development of Servo injection robots continues

The injection molding industry will likely use more servo drives in their machines. This technology has many benefits that can increase productivity and reduce costs for manufacturers. In addition, this technology can provide an increase in performance without adding an excessive amount of maintenance to an existing machine.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/11/20

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/11/20

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/11/20

- Topstar Special | National Science and Technology Workers Day 2022/11/20

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC