We will introduce the structural composition of the servo cylinder robot in injection molding from the four aspects of the drive system, mechanical structure, control system, and arm-end tools. As a qualified engineer or operator, you must understand the structural characteristics of these injection robots so that in addition to being able to control them well, you also know how to repair and remedy them in an emergency.

Servo cylinder robot drive system

A servo cylinder robot’s drive system is essential for providing controlled and dynamic motion, especially in tasks that require precision and complexity. Servo cylinders operate by converting electrical signals into precise pneumatic movements. Their drive systems consist of critical components such as servo valves, pressure regulators, and precision control units. Servo valves regulate air pressure, determining the force and speed of the cylinder, while pressure regulation Keeps the machine in optimal condition. The control unit acts as central intelligence, enabling precise synchronization with the robot movements and other injection molding machine components.

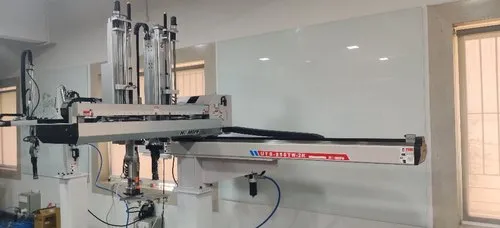

Servo cylinder robot mechanical structure

The mechanical structure starts with a rigid frame capable of withstanding the forces and vibrations associated with the injection molding environment. High-quality materials, usually alloys or reinforced plastics, ensure stability and durability under varying operating conditions. The mechanical structure also adopts a multi-axis configuration to meet the various injection molding needs. This design allows complex movements, including linear, rotational, and even articulated movements, ensuring that the robot can handle complex tasks flexibly. The combination of precision guidance systems and guide rails enables smooth and accurate path movement.

Servo cylinder robot control system

The control system of our servo robot is independently developed and can be customized according to customers. The core of which is a high-precision motion control algorithm. These algorithms ensure precise positioning during critical tasks such as mold opening, closing, and part extraction. Their real-time responsiveness helps improve the overall efficiency of the injection molding cycle. Usually, our control system uses an adaptive path-planning algorithm to optimize the robot’s movement. This intelligence enables the robot to dynamically adjust its trajectory to accommodate changes in production requirements, part geometry, or mold configuration.

End-of-arm tool

The manipulator arm of the servo cylinder robot is mainly used for tasks such as mold handling, part extraction and secondary operations with special tools. To increase operational flexibility, the end-of-arm device features a quick-change system. These systems allow quick tool changes. The design of our end-of-arm tools also features integrated sensors that provide real-time feedback to the robot’s control system. These sensors increase the precision of part handling by detecting changes in part positioning, ensuring accurate placement, and minimizing errors during the injection molding cycle. For part extraction and handling, EOAT typically uses vacuum and pneumatic systems. Vacuum suction cups securely clamp molded parts, while pneumatic actuators facilitate controlled movement.

Integrated with injection molding machine

The Servo cylinder robot is integrated with the injection molding machine. It ensures precise coordination throughout the injection molding process and improves overall efficiency. When combined, they can automate material handling tasks. This includes loading raw materials into hoppers, thus facilitating continuous production without manual intervention. Integrated systems ensure streamlined material flow for uninterrupted manufacturing. Mold changes are simplified when combined, allowing the robot to quickly adapt to different molds to enhance overall production line flexibility and machine adaptability.

At last

By understanding the structural complexity of servo cylinder robots, you can better operate them at work. If you want a detailed understanding before purchasing, this article can also help you. You can consult our customer service on the official website for more technical parameters.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/12/15

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/12/15

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/12/15

- Topstar Special | National Science and Technology Workers Day 2023/12/15

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC