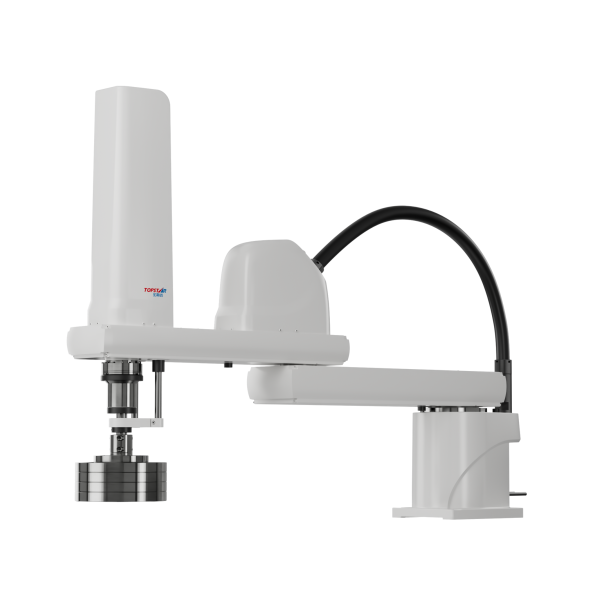

Countries worldwide are at the forefront of energy transformation, and various new energy fields have emerged, including photovoltaics and lithium batteries. Whether it is the silicon wafer, battery, and component production lines in the photovoltaic industry or the process sections of core making, assembly, chemical composition, and module PACK in the lithium battery industry, there are many robots and intelligent automation needs. With the popularization of new energy vehicles and the accelerated penetration of renewable energy, including photovoltaics, these industries have become the main driving force of the industrial robot market. Therefore, Topstar has launched a new TRH10&TRH15 series of high-load SCARA robots specifically for the new energy industry.

More comprehensive and high-load SCARA robots

The TRH10&TRH15 series represents the SCARA robot series, with excellent comprehensive strengths of high load, precision, and speed. The TRH10 series has a 600-1000 mm arm span range, which can flexibly handle various tasks. Its rated load capacity is 10 kg, and the maximum load is 20 kg, so it can easily handle light and medium-heavy tasks. The TRH15 series is even more unique, with an arm span of 800-1000 mm, a rated load of 15 kg, and is more robust with a maximum load of 25 kg. Despite the high load capacity, both series achieve impressive standard cycle times, 0.39 seconds for the TRH10 and 0.48 seconds for the TRH15. These specifications make the TRH10 and TRH15 series ideal for high-speed, heavy-load applications in the lithium battery industry, and these robots are fine-tuned to run at faster speeds without compromising accuracy or stability.

What breakthroughs have been made in the research and development of the RH10&TRH15 series?

First, we must consider the three requirements: accuracy, load, and speed. In designing this series of SCARA robots, we have solved the problems of lightweight and whole machine force deformation, large inertia ratio and control response, significant inertia change and vibration suppression, etc. This makes them faster under the same load and has a more substantial load capacity under the same load. The TRH10&TRH15 series robots have a rapid cycle, high load, and stable operation, inseparable from the high coordination and integration of robot software and hardware and continuous simulation adjustment and verification to ensure the best results.

How do these SCARA robots help optimize production in the new energy industry?

Engineers optimized the TRH10 and TRH15 series for high-speed performance. After extensive testing, the TRH15 series is at least 20% faster than traditional robots in the industry. This speed increase enables various new energy manufacturers to achieve higher output, shorten production time, and improve the overall efficiency of the production line. Whether it is module packaging tasks in lithium battery production or silicon wafer processing tasks in photovoltaic manufacturing, these robots can meet the high-speed needs of the industry. In addition, the ability of these SCARA robots to maintain high speed when handling heavy loads is a significant advantage. Traditional industrial robots often have difficulty maintaining speed and accuracy under heavy loads, but the TRH10 and TRH15 series excel in this regard, providing faster cycles and more substantial load capacity.

What are the specific applications?

In terms of application, it can meet the needs of core making, assembly, chemical componentization, and module PACK in the lithium battery industry. The application of various process segments, such as silicon wafers, batteries, and component production lines in the photovoltaic sector, basically covers the mainstream demand for SCARA robot in the new energy industry. In addition, the TRH10&TRH15 series can also meet the application needs of 3C (screen lamination, silk screen printing, testing, labeling, screw locking), packaging (positioning, molding, assembly, lamination), medical (handling, sorting, assembly, testing, packaging) and other industries.

What benefits can it bring to customers?

Take a leading new energy industry as an example. They proposed increasing the production line capacity to meet the consumer market’s needs. The automated production line transformation process requires the load to be grasped to be nearly 20kg. The four-axis robot with a maximum rated load of 20kg on the market can handle only 10kg, and most of the time, operators must use it at a reduced speed. Therefore, the slow speed of the robot has become their bottleneck. In response to this demand raised by customers, Topstar has developed the TRH15 series of robots. In addition, field testing achieved good performance, and the speed increased by at least 20% compared to traditional industry robots. It also proves that this series of robots can meet the customer’s on-site load requirements of nearly 20kg and are suitable for heavy-load, high-speed application scenarios.

Meeting various challenges in the new energy industry

These SCARA robots improve efficiency and shorten production time, enabling manufacturers to meet the demand for new energy products. Whether for lithium battery production, photovoltaic manufacturing, or other new energy applications, the TRH10 and TRH15 series can help companies stay competitive in the new energy market.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2025/01/17

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2025/01/17

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2025/01/17

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/01/17

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar