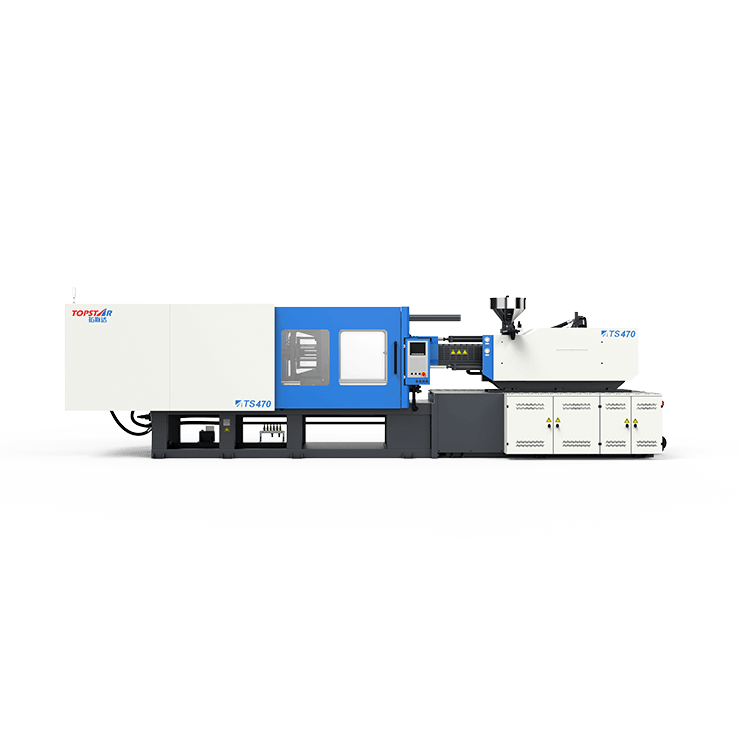

TS Series Toggle Hydraulic Injection Molding Machine(90T-650T)

The TS Series Toggle Hydraulic Injection Molding Machine adopts advanced oil circuit design and is equipped with a professional controller, which enables stable machine movement, high product yield, and fast response speed. At the same time, the oblique row double injection cylinder and linear guide rail are used to make the glue injection more accurate and stable. The screw is made of high-performance nitrided steel, which is durable and efficient, and has wider applications.

Characteristics

- 1. Strengthening the template enhances its resilience, resulting in a 0.2mm/m template deformation. The rigidity ensures product accuracy, particularly in high-speed and high-pressure working conditions.

- 2. Enhanced power, a maximum injection speed of 145mm/s, and an injection pressure of 290MPa, surpassing the standard machine by over 30%.

- 3. Premium-quality screw assembly components are designed to accommodate the high-speed and high-pressure requirements of PC and TPU shell parts.

- 4. Utilize ceramic heating elements and implement temperature control at the material inlet, enhancing temperature precision and sensitivity to boost yield.

- 5. Tightly integrated with auxiliary systems and using KEBA controller to ensure convenient and efficient operation.

- 6. Brand new diagonal hinge layout can realize ultra-long stroke mold opening, mold opening position accuracy<mm, and fast and stable platen movement.

Product Accessories

- 1. Diagonal double injection mold shift oil cylinder and linear guide, more accurate and stable injection.

- 2. Optimized and upgraded platen, with reliable structure and small deformation, can effectively protect the equipment and improve the service life of the mold.

- 3. Standard screw: high-performance nitride steel, durable and efficient, wide application.

- 4. High color mixing/high mixing screw: to meet the high color mixing products, easy to change color custom screw: specially customized plasticizing components for different products, such as PC, PA, etc.

Adequate supply of goods, available for delivery within 35 days.

Description

TS series toggle type hydraulic injection molding machine (90T-650T)

TS series toggle-type hydraulic injection molding machine (90T-650T) adopts an advanced oil circuit design and is equipped with a professional controller, which makes the machine stable, has high product yield, fast response, precise control, simple operation, and meets various process requirements. Excellent strength during injection molding is achieved through carefully designed and optimized connectors, advanced guide rails and sliders, and effective structural vibration prevention measures. This not only produces precise and high-quality injection molded parts but also improves the reliability of the production line. With a 30% increase in power, they can handle a broader range of tasks. Whether a simple injection molding project or a complex production process, the overall power configuration can ensure that the equipment operates efficiently and stably, provides first-class injection molding products, and improves overall production efficiency. The TS series toggle hydraulic injection molding machine uses high-quality screw components, which can perform well under harsh working conditions of high pressure and high load. It also uses ceramic heating elements, feed inlet temperature control, and seamless integrated auxiliary systems to improve overall stability and efficiency, product quality, and production efficiency.