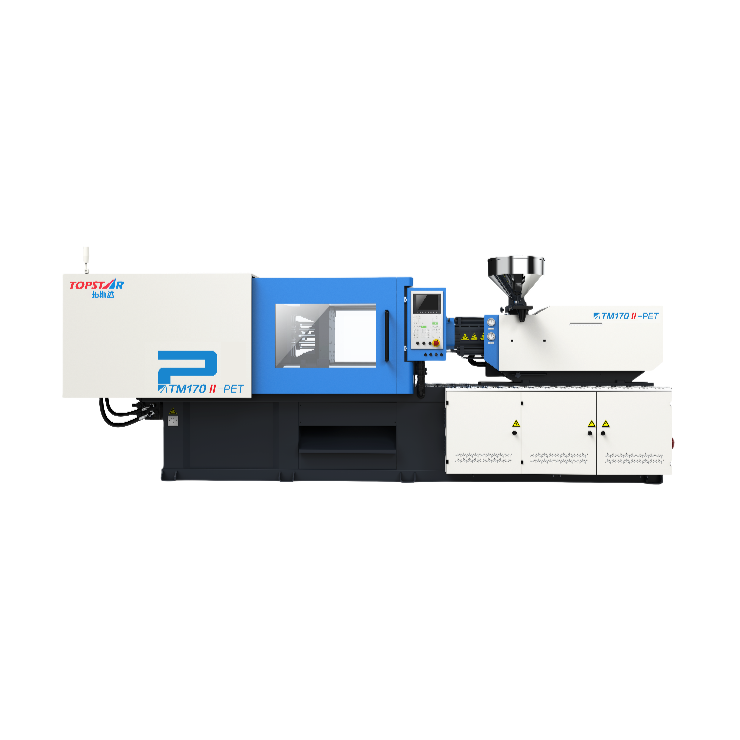

TMII-PET Series Injection Molding Machine(170T-470T)

TMII-PET series injection molding machines are designed for precise and fast production of high-quality preforms. The preform injection molding machine series excels in speed, professionalism and efficiency. It is a high-rigidity, high-efficiency, energy-saving, and matching injection molding solution.

Characteristics

- Template strength upgrades are needed to ensure better product accuracy.

- The targeted oil-proof design of the machine frame provides a more compact size of the whole machine and is more suitable for a clean workshop.

- PET special screw assembly, good plasticizing quality and high efficiency. Can reduce the plasticizing temperature and AA value, effectively improve the shrinkage of products and improve transparency.

- Specially enlarged hydraulic motor with high torque and good smoothness at low speed.

- Especially by increasing the ejecting force and ejector stroke to meet the requirements of PET product deformities.

Application Industries

- Carbonated beverages, bottled water, spices, cosmetics, liquor, dried fruits and candies, etc.

Adequate supply of goods, available for delivery within 35 days.

Description

TMII-PET Series Injection Molding Machine(170T-470T)

The TMII-PET series injection molding machine has upgraded the template strength, which improves the stability and precision of the machine during the injection process. The entire frame has been designed to prevent oil pollution and maintain the high cleanliness required for preform application. The whole machine is smaller and more suitable for clean workshops. It also uses a screw combination dedicated to PET to ensure uniform melting and consistent material flow. This design reduces the plasticizing temperature and AA value, reducing energy consumption and improving production efficiency. The lower AA value can also improve the quality of PET products, which is very important for plastic containers where taste and transparency are crucial. At the same time, it also improves shrinkage and transparency to enhance the dimensional stability and transparency of PET products, which can meet higher market standards.

Unlike the standard injection molding machine model, the TMII-PET series has an oversized hydraulic motor to provide the high torque required for preform injection molding, which is essential for processing high-viscosity PET materials. In addition, the enlarged hydraulic motor also brings low-speed stability, ensuring precise control during the injection stage and reducing defects. The TMII-PET series also increases the ejection force and extends the ejection stroke to achieve efficient demolding. Sufficient force and stroke length ensure that PET products can be ejected smoothly without damage, and faster ejection speed shortens cycle time and improves overall production efficiency.