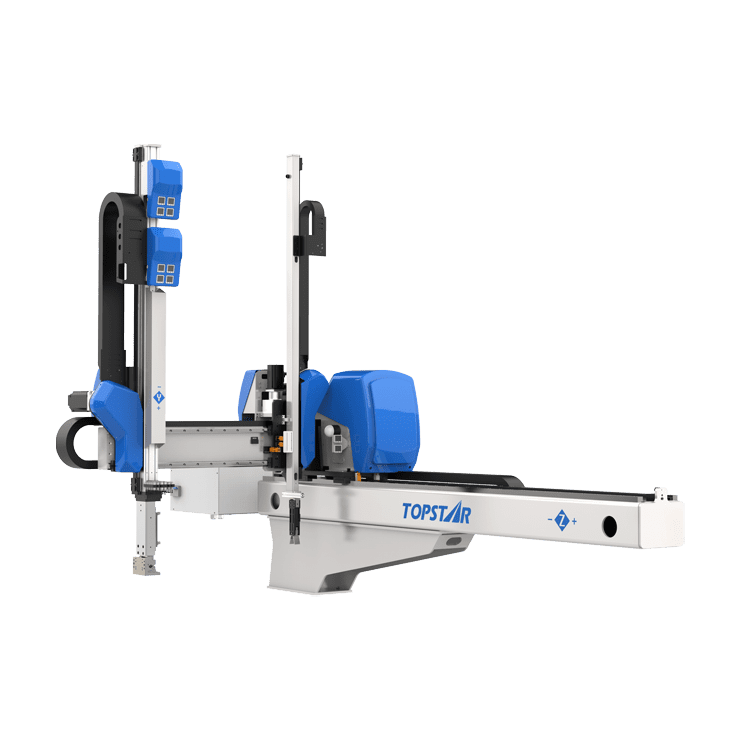

GU Series AC Servo Injection Robot

The fifth generation of "five-in-one servo-driven injection robot" has achieved hardware precision energy saving and software integrated communication through the upgrade of core component technologies such as control system and servo drive. It is suitable for injection molding machines with a clamping force of 30-450T, can grab loads of 3kg-8kg, and is equipped with fixed and open operating systems.

Product Features

High precision

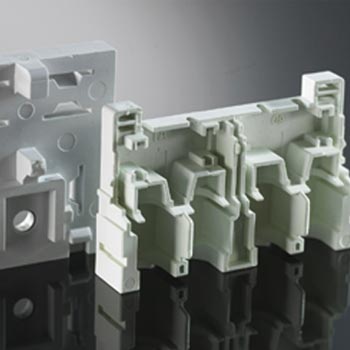

- The newly added vibration suppression function is very suitable for high-precision removal of plug-in molding, etc.

High performance

- Self-developed control system can be developed and customized according to customer needs.

- Built-in dual system customers can choose freely.

- Standard RS485 communication interface, support MODBUS RTU communication protocol.

- Use a large-bore cylinder with greater thrust and a 20% load increase.

High speed

- Lightweight aluminum alloy arm, the machine reduces 20 structural components and weight by 20%.

- The main arm is made of lightweight and high-strength A6061 material to improve overall operating performance.

High energy-saving effect

- Total DC bus technology saves 10% energy and reduces electricity costs by 10%.

- Add a servo automatic OFF function, and the servo motor stops powering on when in standby mode, saving 10% electricity.

- Real-time remote monitoring, equipment operation data statistics, analysis and life management.

Optional series

- 1.EU-50 (suitable for 30-150IMM tons)

-

2.EU-50S (suitable for 30-150IMM tons)

-

3.EU-80 lll (suitable for 100-120IMM tons)

-

4.EU-80s lll (suitable for 100-120IMM tons)

-

5.EUW-80 lll (suitable for 100-120IMM tons)

-

6.EUW-80s lll (suitable for 100-120IMM tons)

-

7.EUW-120 ll (suitable for 350-400IMM tons)

-

8.EUW-120s ll (suitable for 350-400IMM tons)

-

9.EU-120 ll (suitable for 350-450IMM tons)

-

10.EU-120s ll (suitable for 350-450IMM tons)

Adequate supply of goods, available for delivery within 35 days.

Description

The fifth generation of "five-in-one servo-driven injection robot"⇓

The self-developed control system algorithm and "five-in-one" servo drive enable one servo drive to directly control five servo motors, making the removal control more precise, energy-saving, and intelligent. The multi-track application of the self-developed open system only needs to modify the program, servo parameters, and mechanical parameters with the hand controller or modify the application program according to the needs, which can realize the removal path such as traction, undercut, sliding, oblique line and even irregular, and can also realize special actions such as arrangement, stacking, counting, and sampling.

It can support the injection molding machine call signal and realize integrated operation. The control system automatically optimizes the removal process and improves the injection molding efficiency of the production line. It realizes synchronous linkage with the mold opening process. The early arrival and "automatic follow-up" functions reduce abnormal alarms and equipment maintenance times, further improving production efficiency.