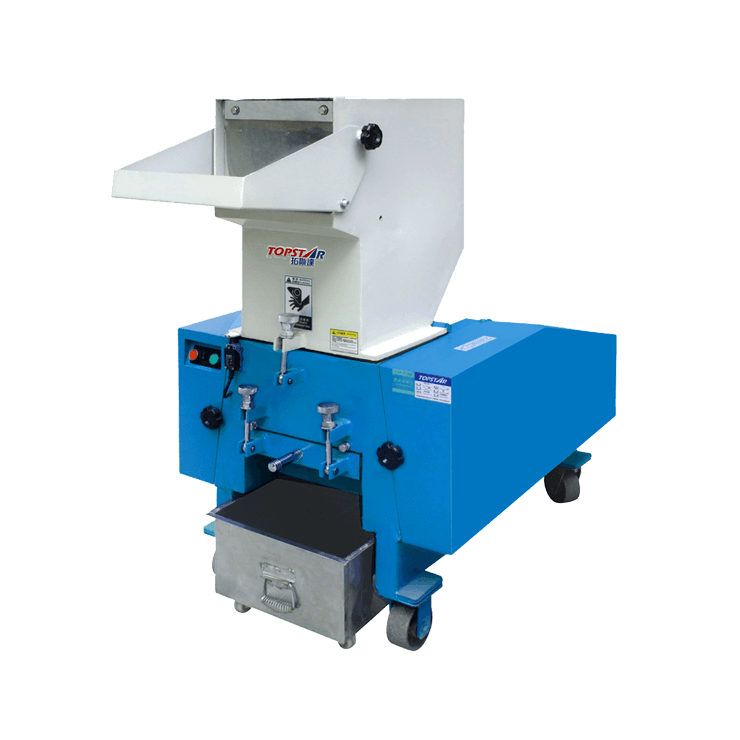

Granulating and Recycling System

Mainly used for crushing nozzle materials at the machine side. It is suitable for recycling all kinds of hard and brittle plastic nozzles. It is especially suitable for crushing and recycling hard nozzle materials such as PC, nylon, and ABS. It adopts a screen-less design, and the crushed particles are even and the dust content is low. Very rarely, the feed hopper adopts a double-layer sound insulation design, the inner layer is made of stainless steel, and has a visual material window.

Features

- 1. Non-mesh screen design, well-proportioned granules, and less powderpollution.

- 2. Optimized structure of machine with small footprint which is especially suitable for the limited space of workshop to use.

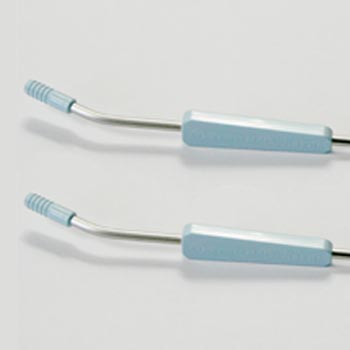

- 3. Blades are made of excellet alloy material with long service life.

- 4. 30 sec instant recycling system to keep regrind material free from color changing by oxidation or damping.

- 5. Low speed at 20~28 rpm, power saving, less noise.

- 6. This unit is driven by shaft gear-motor, no need oil.

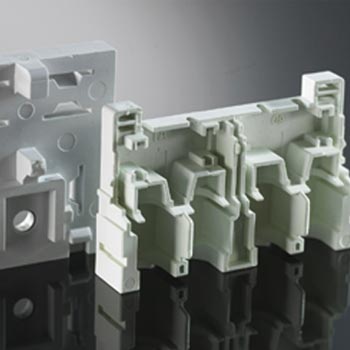

Application Industries

- 1. Electronics

- 2. Containers

- 3. 3C home appliances

- 4. Cosmetics

- 5. Auto parts

- 6. FMCG

Adequate supply of goods, available for delivery within 35 days.

Description

Unique Features of Granulating and Recycling System⇓

TOSTAR's granulation and recycling system adopts a screenless design, low-speed operation of 20~28rpm, and a tooth-gnawing tool design. It is specially designed to crush all types of hard and brittle plastic defective products, and machine-side crushing and recycling of faulty products. It has the advantages of low speed, ample torque, low noise, less dust generation, and easy operation. It also has the advantages of uniform product crushing particles and excellent crushing effect. There is no overheating during equipment operation, long service life, and safer operation. In addition, the 30-second instant recovery system driven by a shaft gear motor can reduce damage such as humidification and oxidation of water-coated materials.