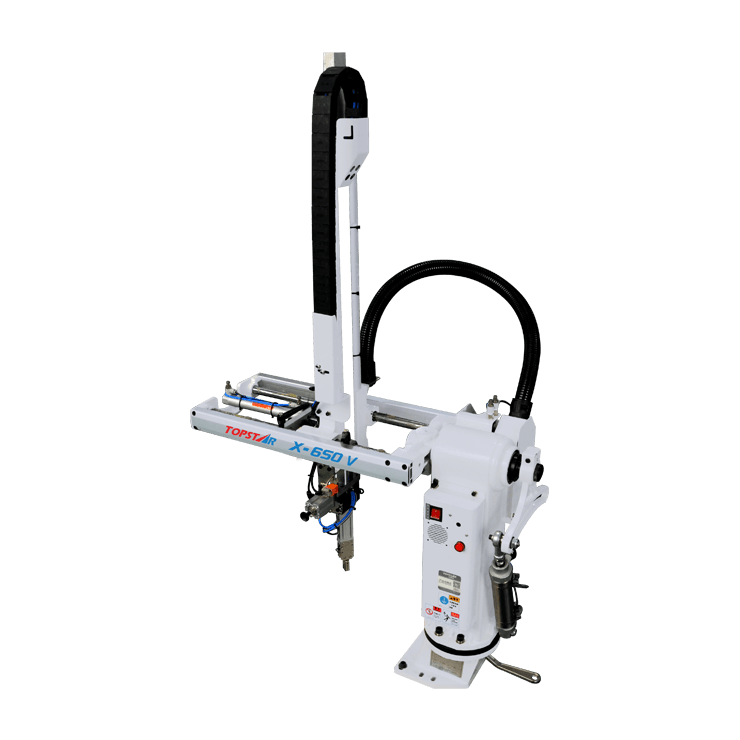

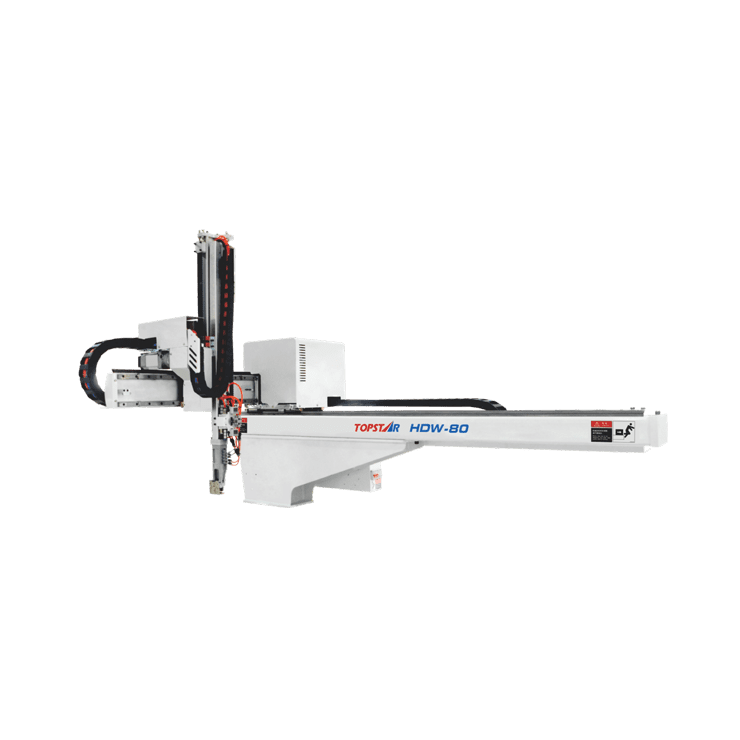

Injection robot series

Injection Robot

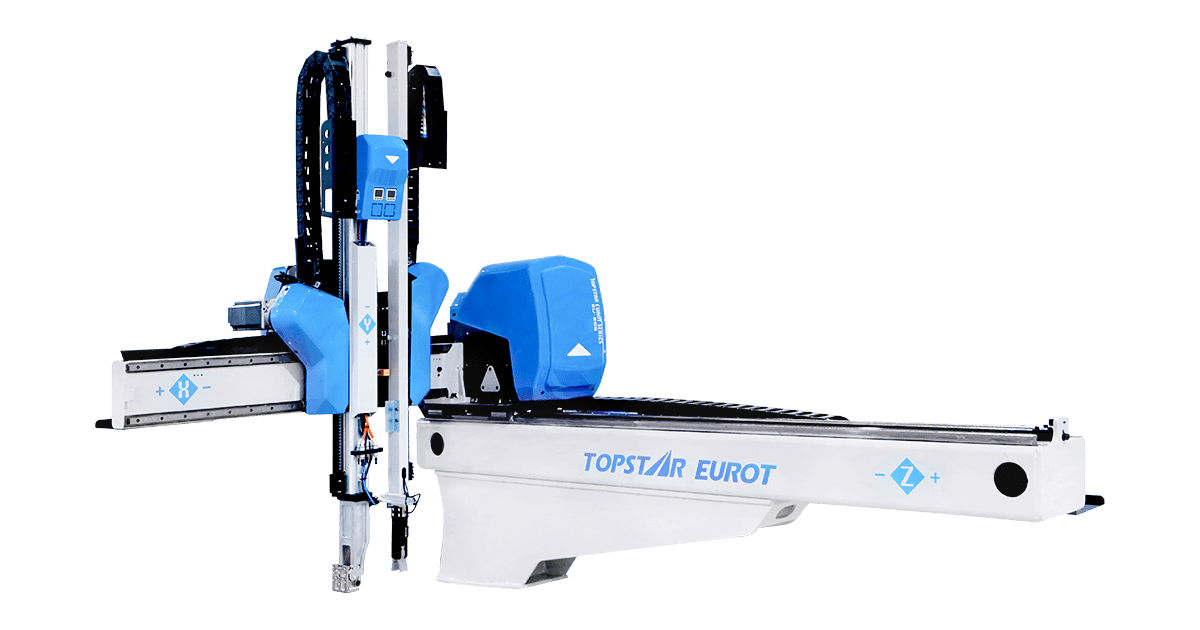

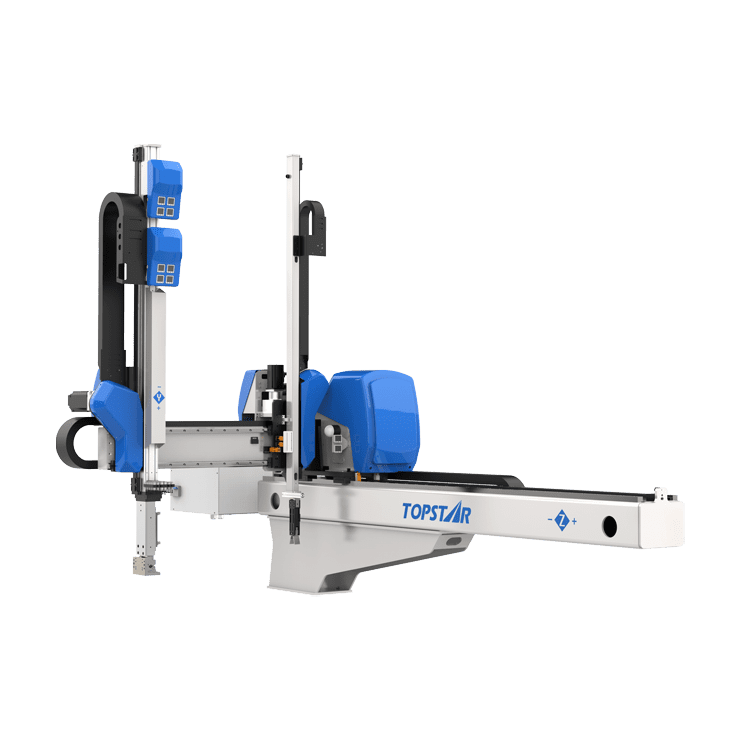

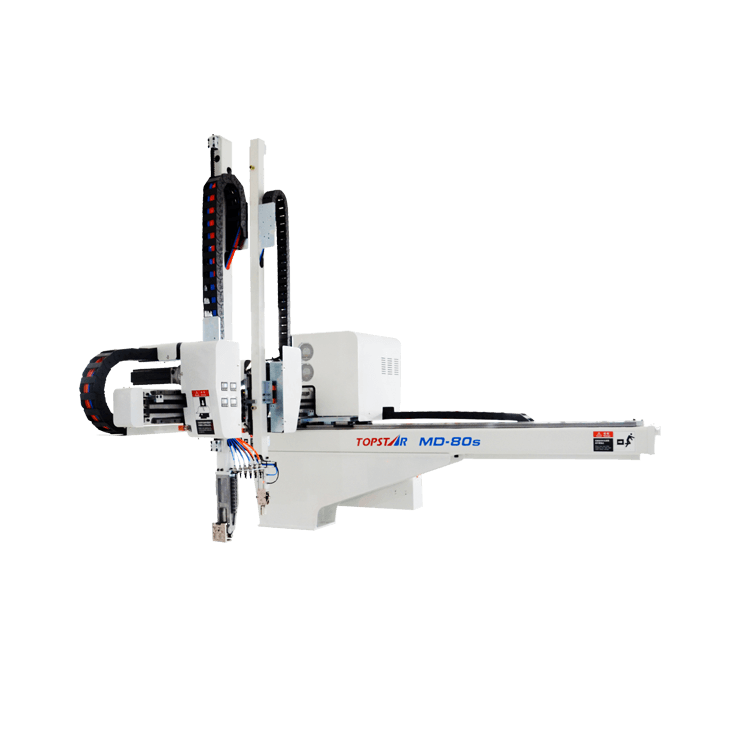

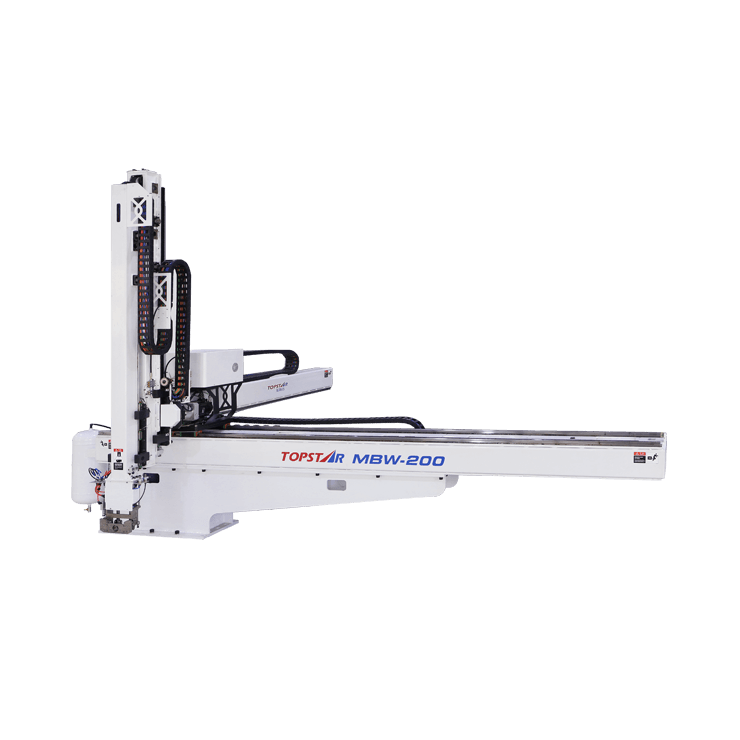

The main series of injection robots are the EU series, EUW series, MD(E) series, etc. Adopting an independently developed control system, it has the characteristics of high speed, high precision, and high performance. In terms of energy saving, power consumption is reduced by 10%. In terms of speed, the linear speed is increased by 20%. When loaded, the maximum lifting capacity increases by 20%. The series can implement remote monitoring, data analysis, and life management.

Products

Injection Robot

Products

Injection Robot

- High Performance

- Reliability

- Durability

- Universally Applicable

The fifth generation of "five-in-one servo-driven manipulator" technology

Features of the manipulator: precise, energy-saving, and intelligent five-in-one servo

- “Five-in-one servo drive” enables one servo driver to directly control five servo motors, each CPU chip controls two axes, and the maximum power of each axis is 750W. This provides a powerful power for the robot. Combined with the multi-axis common busbar design, the energy efficiency is improved by 20%.

Support multi-track application

- The self-developed open system can bring great convenience to the operator. Only by using the hand controller to modify the program, servo parameters and mechanical parameters or modify the application program according to the needs, can it realize traction, hook, slip, oblique line and even irregular removal paths, and can also realize special actions such as arrangement, stacking, counting, sampling, etc.

The concept of integrated process from communication to integration

- The manipulator can support the host call signal, and realize integrated operation, and the control system automatically optimizes the removal process link to improve the injection molding efficiency of the production line. It solves the problems of ejection position deviation and uncoordinated suction time leading to removal failure and equipment alarm shutdown.

- It realizes synchronous linkage with the mold opening process, and the early arrival and “automatic follow-up” functions reduce the number of abnormal alarms and equipment maintenance, further improving production efficiency. The production efficiency of each injection unit is increased by 5%.

Training for Installation and Operation Correctly

Topstar Service

We have a comprehensive after-sales training system. To address potential issues and ensure optimal operation, we provide you with the necessary training resources for installing and operating the packaging machine.

- Instructions for Use – Installation Steps and Operating Precautions

- Video demonstration of installation and debugging

- On-site training – additional service fee required

Technical Support

Whether your business is located in Europe, North America, or the Middle East, we provide global services, and our experts are on call to provide technical support services through video calls or on-site assistance. Services include:

- First installation and debugging of equipment

- Daily debugging and maintenance

- Emergency fault assistance

- Equipment optimization services

The Machinery Industry Professionals

- Customized Requirements

- Solutions

- Professional Packaging

- Delivery & Installation

- 24H Technical Support

The Topstar team delivered the Water & Electric Engineering project efficiently and perfectly in a complex environment with an urgent delivery schedule.

LUXSHAREICE

From EEA series to TE series, we see the continuous pioneering and innovative spirit of Topstar in the field of injection molding machines.

Dme Udaykumar

The robotic arms were installed and ran smoothly, which greatly improved our production efficiency!

Thai A-Tech

Listen To The True Voice Of Customers

We sincerely appreciate that more than 15,000 customers have witnessed the TOPSTAR growth and long-term supports.