Good Product

CNC Machine

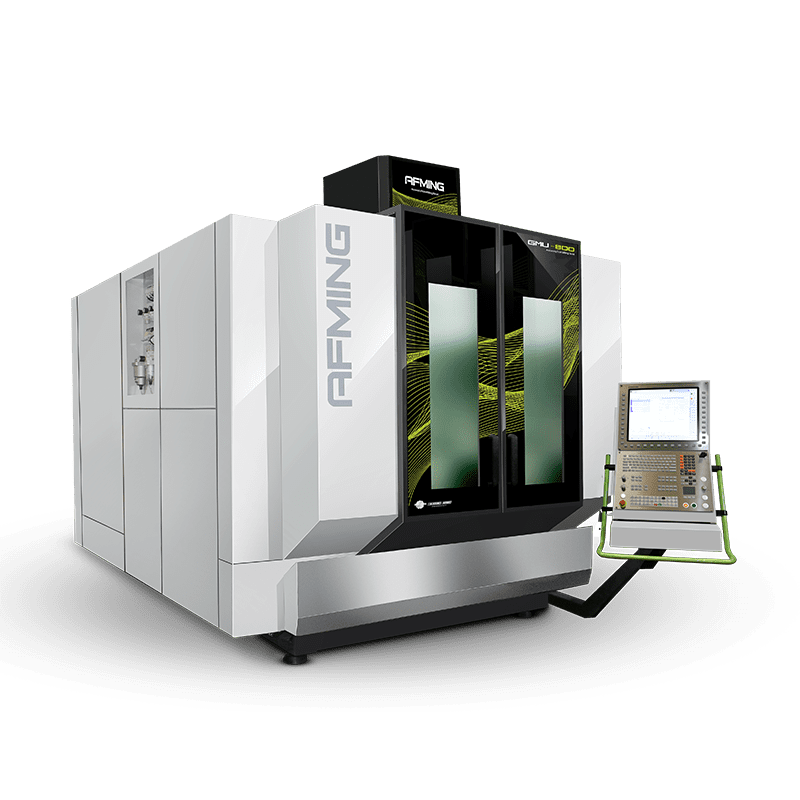

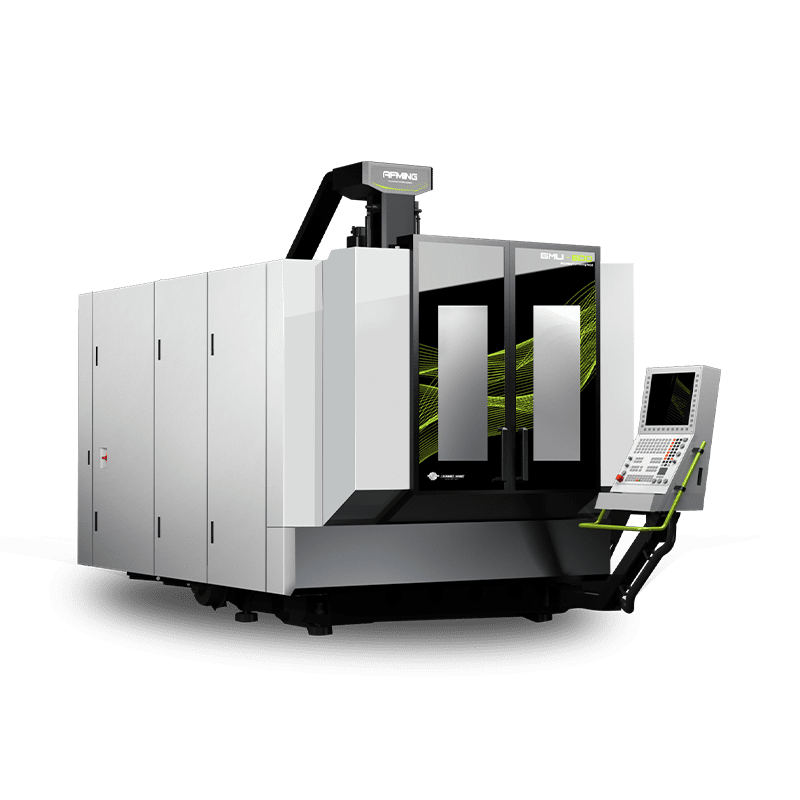

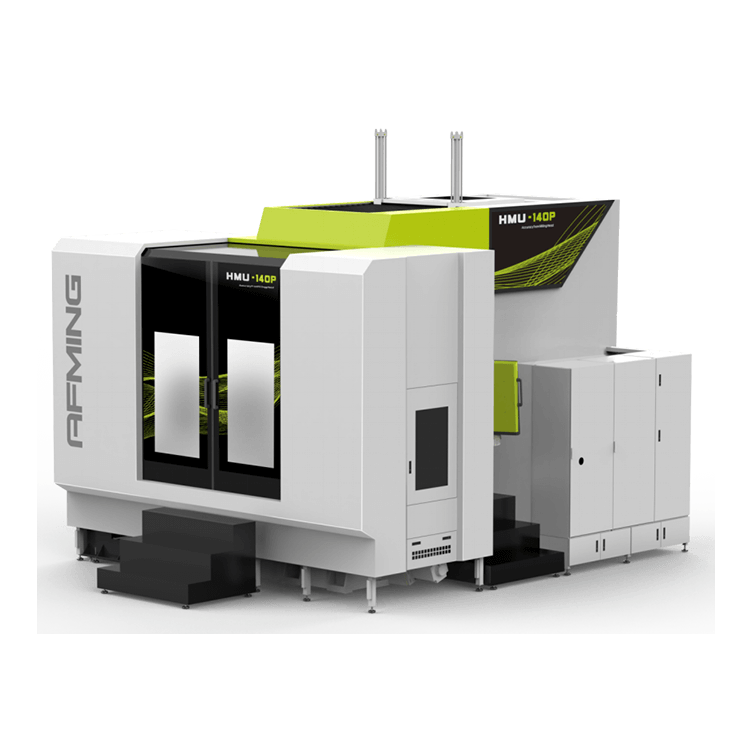

The CNC machine tool series includes the GMU800 five-axis machining center series, the GMU600 series five-axis machining center series, the vertical machining center, and the drilling and tapping center series. Equipped with German high-end spindle technology and high-rigidity and high-torque gear-driven A/C cradle turntable technology, it can achieve more powerful torque output at the same level and meet high-speed, efficient, and high-precision processing requirements.

Products

CNC Machine

Products

CNC Machine

- High Performance

- Reliability

- Durability

- Universally Applicable

Did you know?

High-Security Equipment

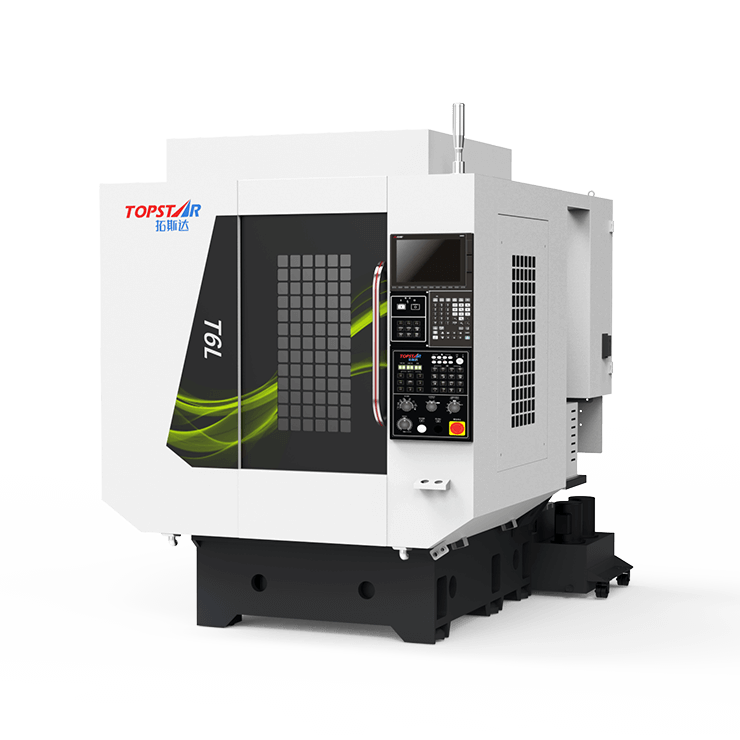

Topstar’s direct press injection molding machine directly generates high pressure from the clamping cylinder on the plate, and the force point is in the same direction as the pressure in the cavity to achieve central clamping.

The plate deformation is quite small, and the product is not easy to flash. The force of the mold is balanced, and the service life of the machine is greatly extended.

For equipment of the same tonnage, about 10% of electricity can be saved after using the center clamping.

The plate deformation is quite small, and the product is not easy to flash. The force of the mold is balanced, and the service life of the machine is greatly extended.

For equipment of the same tonnage, about 10% of electricity can be saved after using the center clamping.

Training for Installation and Operation Correctly

Topstar Service

We have a comprehensive after-sales training system. To address potential issues and ensure optimal operation, we provide you with the necessary training resources for installing and operating the packaging machine.

- Instructions for Use – Installation Steps and Operating Precautions

- Video demonstration of installation and debugging

- On-site training – additional service fee required

Technical Support

Whether your business is located in Europe, North America, or the Middle East, we provide global services, and our experts are on call to provide technical support services through video calls or on-site assistance. Services include:

- First installation and debugging of equipment

- Daily debugging and maintenance

- Emergency fault assistance

- Equipment optimization services

The Machinery Industry Professionals

- Customized Requirements

- Solutions

- Professional Packaging

- Delivery & Installation

- 24H Technical Support

The Topstar team delivered the Water & Electric Engineering project efficiently and perfectly in a complex environment with an urgent delivery schedule.

LUXSHAREICE

From EEA series to TE series, we see the continuous pioneering and innovative spirit of Topstar in the field of injection molding machines.

Dme Udaykumar

The robotic arms were installed and ran smoothly, which greatly improved our production efficiency!

Thai A-Tech

Listen To The True Voice Of Customers

We sincerely appreciate that more than 15,000 customers have witnessed the TOPSTAR growth and long-term supports.