Find Out Plastic Injection Molding Machine Price in 2024

2022/01/31 By Topstar

How much does a plastic injection machine cost?

When individuals or businesses need to use machines with the use of plastic forming but are wondering about plastic injection molding machine price? The news section will give you the most accurate data on popular products on the market for you to choose from.

The price of a plastic injection molding machine starts from $11,000. It can vary according to function and performance.

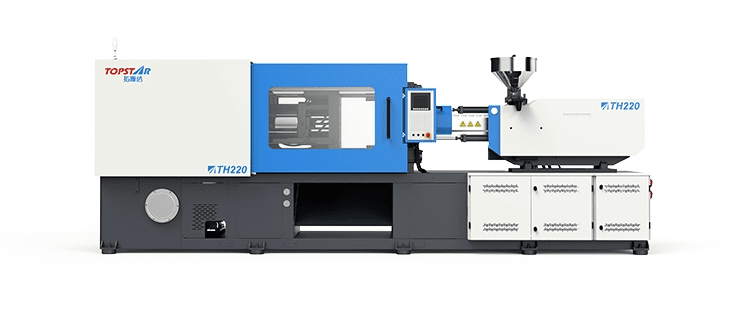

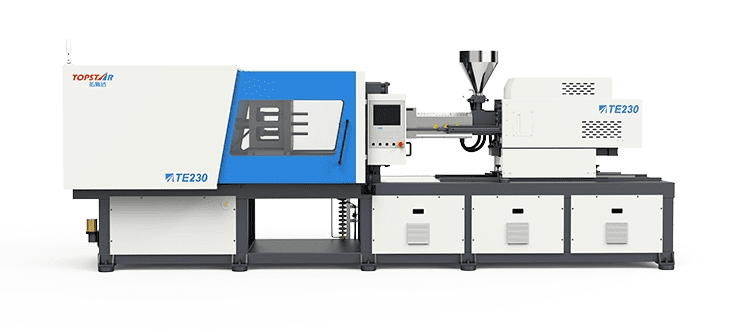

Please follow the information below on TopStar Machine.

What is a plastic injection machine?

To answer the question of how much does a plastic injection machine cost? Knowing its structure and function is very important.

A plastic injection molding machine, a plastic injection molding machine, a plastic injection molding machine, a plastic injection machine, etc., has a separate structure to create mass plastic products. Plastic injection molding machine price works on a pre-programmed principle.

Different types of machines will be distinguished in terms of the installation of parts. However, most of them have the same operating principle.

Structure and application of plastic injection machine

Plastic injection part: Funnel-shaped design, helping to put plastic beads into the machine to melt. The injection of plastic is thanks to the screw and nozzle system;

Mold clamp: Helps to fix the sample, shape the product, and push the plastic out of the machine.

There are two types: fixed mold clamp and movable mold clamp. The fixed mold is precisely positioned at the machine. The movable mold opens and closes according to a pre-programmed cycle. The plastic injection molding machine price has an automated process that saves labor, time, and, most importantly, assets, creating high efficiency in work.

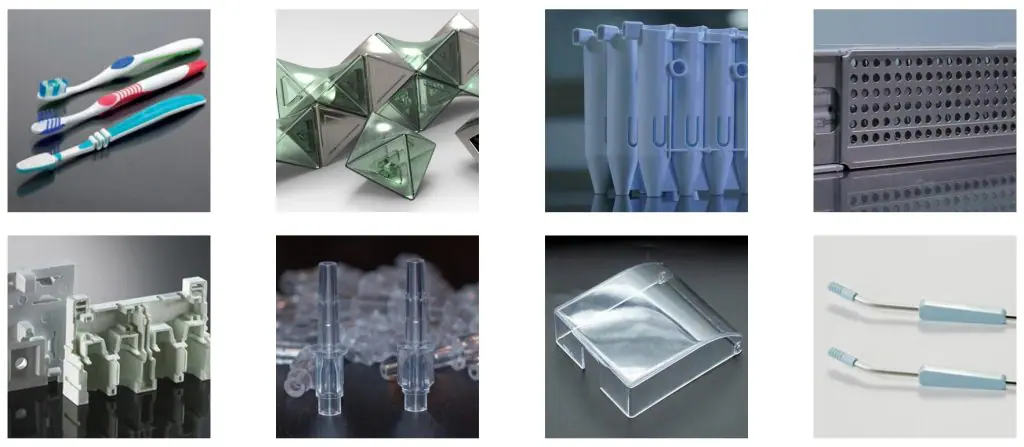

From having such many advantages, plastic injection molding products are widely applied in all areas of social life. Specifically:

- Manufacturing, packaging industry: Household appliances, stationery, and electronics.

- Pharmaceutical industry: Producing drug cases, gloves, test tubes, syringes.

- Decoration and interior industry: Partitions, sanitary ware.

- Dressing date: Protective gear, buttons,…

How much does a plastic injection machine cost?

How much does a plastic injection machine cost? It is unthinkable to have a specific number because the cost is countless. Below, we will share some criteria that affect the plastic injection molding machine price list and product quality. It is essential that the higher the price, the better the press will be. This depends mainly on the needs of each customer segment.

Origin of plastic injection machine:

Each brand of plastic injection machine will have a different price. Currently, famous machine suppliers such as Japan, Korea, Germany, and China are on the market.

Product features: The more built-in functions a product has, the higher the price. Besides, the smoothness of the combination is also a criterion for selling plastic injection molding machines at prices.

Distribution address: The evaluation of a good, suitable plastic injection machine business place depends on the legality of the unit, information on the representative, and documents proving the product’s origin.

Capacity of the machine: There are many plastic injection machines, such as inclined machines, vertical machines, or mini plastic injection machines. The power of the devices has a sharp difference. The larger the product’s capacity, the more plastic it will produce and the higher the price.

Update the latest plastic injection machine price list in 2021

With the latest updated plastic injection molding machine price list below, you can clarify the question of how much a plastic injection machine costs.

The cost of these products ranges from US $ 4700 depending on the criteria as analyzed above.

Note: How much does a plastic injection machine cost? Depending on each store, location, and transaction time, it may change up and down. How much does it cost to get the most accurate information about plastic injection molding machines? You need one click, and the staff will contact you directly and share the latest price list.

The policy of free shipping and return

Moreover, the policy of free shipping and return within 30 days will create maximum convenience for customers in the product selection process.

In the process of plastic injection molding machine price, the finished product may have unnecessary defects. Each defect has its cause and has its remedy. Below, Smart PM will guide you to adjust mainly for the injection molding process when the product has flaws.

Product error has the wrong assembly size!

The reason this error occurs is that the plastic material line has a shrinking phenomenon. However, plastic shrinkage during the injection cycle and after the product is removed from the mold. Each type of plastic material will have a different shrinkage.

Factors that affect shrinkage include:

Effect of pressure: The longer the pressure retention time, the higher the maximum pressure in the mold cavity, resulting in lower shrinkage. Plastic injection molding machine price, but the pressure in the mold will change with the flow length, so the shrinkage at different locations will be additional but not uniform.

Effect of temperature: The higher the plastic flow temperature, the higher the shrinkage because the material compresses less into the mold because the plastic expands more. As for using semi-crystalline resin, the mold temperature affects the shrinkage because it affects the cooling time.

Effect of molecular orientation: Moreover, the molecules are oriented by shear stress, which is then retained by the combined cooling process. The plastic molecules return to the free state when in normal conditions and not in the mold. The flow shrinkage will be more significant for a plastic injection molding machine price than the directional shrinkage.

Factors affecting the occurrence of warping errors include

Effect of pressure: When there is a pressure drop along the plastic flow, the compression of the material will be uneven. If you want uniform compression, increasing the maximum compression pressure in the plastic injection molding process is necessary.

Effect of temperature: When the mold temperature increases, the product cools slowly, and the warping will increase.

Effect of current orientation: Plastic injection molding machine price, when the resin is reinforced with fibers, the exposure occurs due to sliding and cooling. If the direction is uneven, there is a risk of warping.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/01/31

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/01/31

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/01/31

- Topstar Special | National Science and Technology Workers Day 2022/01/31

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC