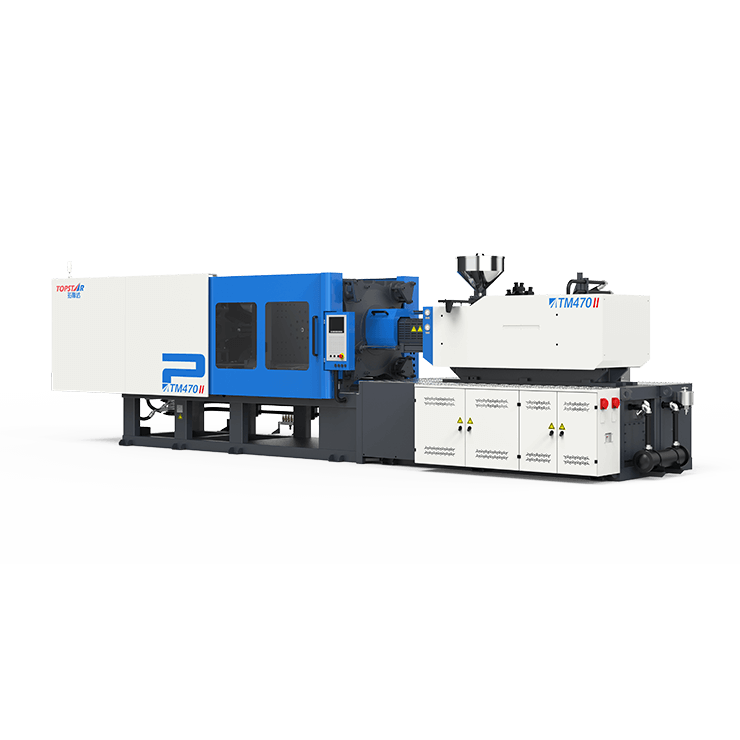

Plastic injection molding machine: Features and Applications of the TM ll Series

2024/02/16 By Topstar

The TM II series of Plastic injection molding machine has strong power, high efficiency, energy saving, reliability, simplicity, and ease of use. Suitable for electronic, optoelectronic, medical, and other plastic products. This guide will introduce you to its unique features and multi-functional applications in detail.

Product accessories for Plastic injection molding machine

As for the control system comes standard with a KEBA controller, PHASE motor, and DELTA drive combined with our independently developed control program to make production control more precise. The injection unit has a standard electroplating screw. It controls the temperature of the discharge port to promote higher production efficiency and a more comprehensive range of applicable rubber materials. Using oblique double injection cylinders and linear guides makes injection more precise and stable. At the same time, we also optimized the clamping design to strengthen and stabilize it.

Product features of Plastic injection molding machine

The plastic injection molding machine has an automatic compensation function in the mold opening position, can cooperate with the injection molding robot for precise grasping, and can be highly integrated with the auxiliary machine system. The new inclined machine hinge layout can realize ultra-long stroke mold opening. The mold opening position accuracy is controlled within <±1mm, making the template movement fast and stable. We have increased its ejector pin thrust by 20%, which is more conducive to the demoulding of connectors and plug-in products. The plastic injection molding machine has fully upgraded its oil circuit system, enabling fast differential clamping operation. Additionally, it increases overall machine efficiency by 15%, boosts servo power by 20%, raises firing speed by 20%, and enhances melt speed by 10%, thereby greatly shortening the injection molding cycle.

Application in daily necessities

Among daily necessities, plastic injection molding machines can produce various daily necessities such as containers, bottles and packaging materials. Packaging for beverages, cleaning and personal care products, storage boxes, disposable tableware, and a wide range of goods are produced using injection molding technology. Learn more in the video below.

Application in household appliances

The versatility of plastic injection molding machines reflects the ability to achieve a variety of shapes, sizes, and designs. Home appliance enclosures often require complex functionality, custom textures, and a variety of finishes. Injection molding meets these requirements, producing visually appealing and ergonomically designed housings.

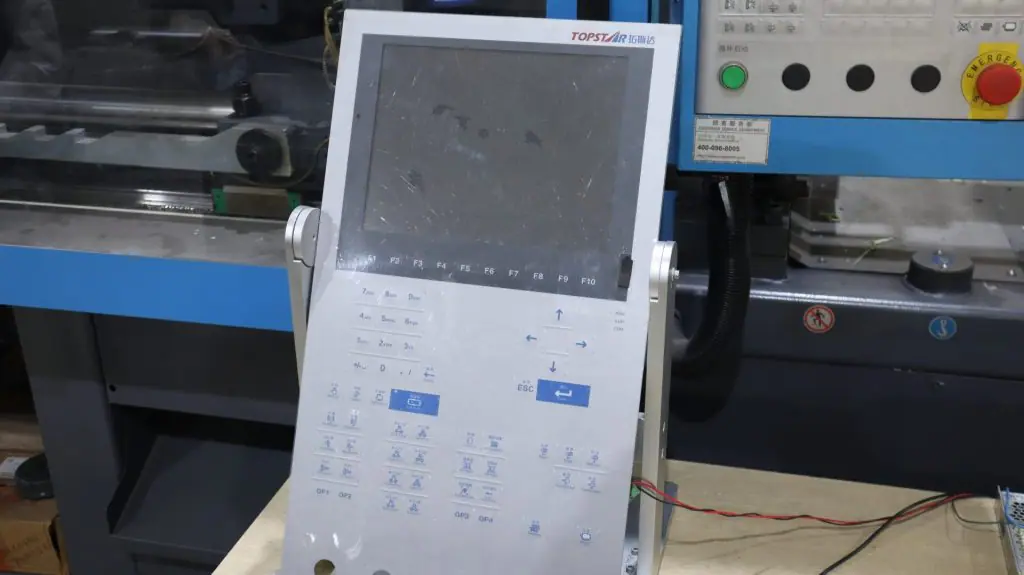

User friendly interface

The user-friendly interface usually uses a touch screen or graphical user interface (GUI). The developers have designed the computer operation interface more humanely through the secondary development of the control system. It provides an intuitive platform for the operator to interact with the machine.

The interface lets users fine-tune molding by entering parameters such as temperature, pressure, and injection speed. Interfaces often incorporate real-time monitoring and feedback mechanisms to facilitate more accurate navigation. Operators can actively observe key metrics such as temperature distribution, cycle times, and pressure readings during molding. This real-time data enables users to make instant adjustments to ensure the production of high-quality plastic parts.

Elevating Injection Molding with the TM II Series

The TM II series plastic injection molding machines make injection molding easier and more efficient and enable mass production. You can leave a message on our official website if you want more information.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/02/16

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/02/16

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/02/16

- Topstar Special | National Science and Technology Workers Day 2024/02/16

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC