How to select best plastic injection molding machine?

2021/12/16 By Topstar

What are the main features of Toggle Injection Molding Machine

Here are some examples taking into account the basic requirements. Certain models of plastic injection molding machine may have their own characteristics that are unique to a given product. It may tilt the customer’s choice in their favor. When working with a schematic diagram, you must adhere to the following parameters.

The distance between the columns uniquely determines the geometric parameters of the shapes used. Before assembling the entire system, it is required to check how compatible the molds are with the selected injection molding machine model.

Inconsistency leads to the impossibility of mutual pairing and work in general. The width and height of the mold must be less than the distances at which the columns are located. It is also necessary to take into account that there must be compliance with:

- the size of the plate

- the opening parameters

- and also the column part must withstand the mass of the replaceable mold together with the processed plastic

Typically, injection molding machine manufacturers recommend certain indicators, therefore, when buying; it is advisable to require instructions from the seller, at least partially.

What is the ideal size for plastic injection molding machine?

When accounting for this indicator, there is no big trick. For example: you have an injection molding machine with 520×520 plates, with a distance between the columns 420×420.

For this plastic injection molding machine, a mold is suitable not only up to 400×400, but also 400×520, that is, so that it passes between the columns on one side and does not go beyond the plate on the other side.

Thus, you can fit the mold with a large number of places, and therefore, increase productivity and reduce the cost of the final product.

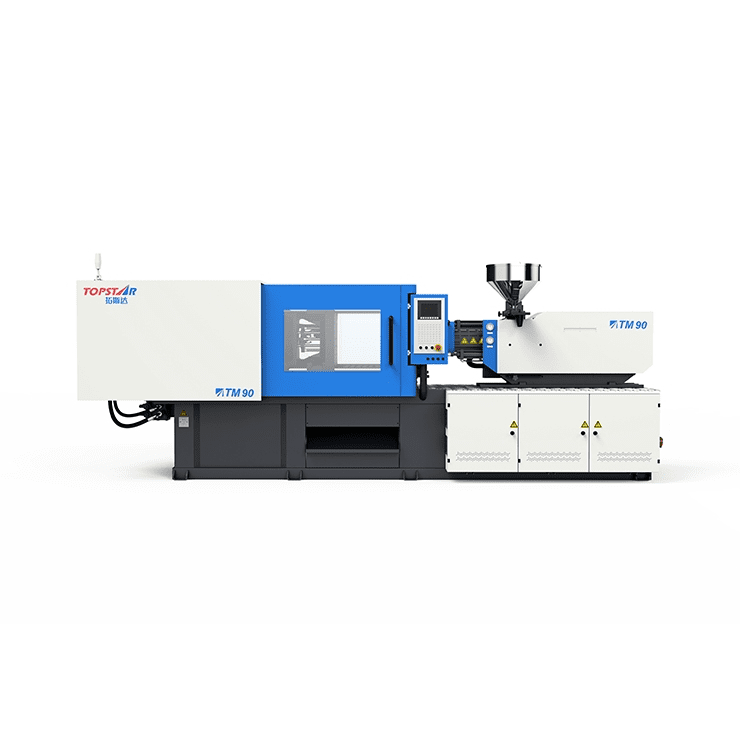

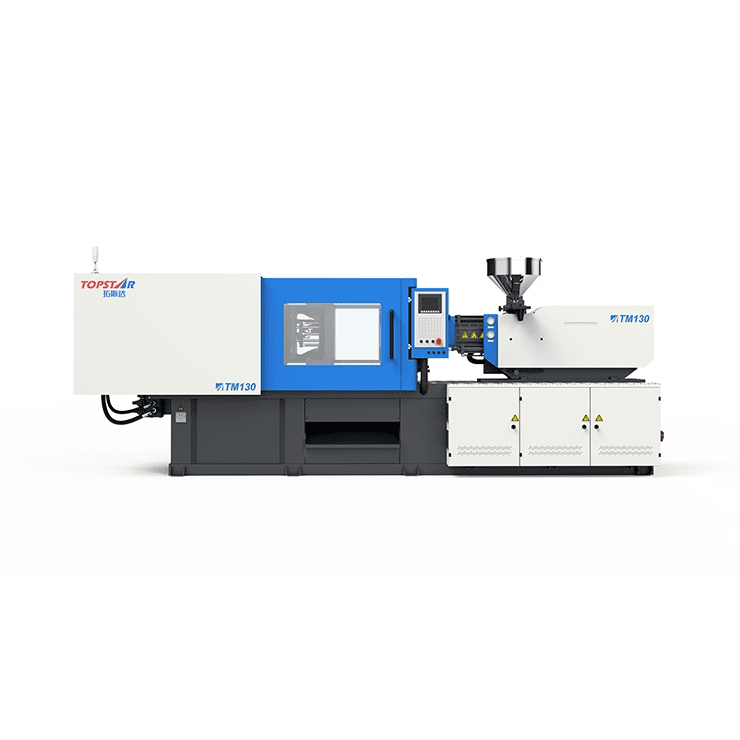

For such solutions, for example, the manufacturer of injection molding machines Top Star Machine has a special TM Series Toggle Injection Molding Machine series with non-standard plates.

Estimated clamping force of the plastic injection molding machine

This indicator is strictly predetermined for each type of plastic mass. The appearance of cracks and adhesions, as well as colored parts will have an uneven color with streaks, spots and stripes.

Therefore, it is necessary to use a strictly defined value developed by the clamping force. This figure is so important that manufacturers often enter it in the markings of the brand, model or modification of a particular plastic injection molding machine.

What are the mechanical locking devices?

After the injection of the polymer mass into the mold under enormous pressure, a counter resistance force arises, trying to separate the component parts. Mechanical locking devices are often based on crank-link mechanisms to achieve the required performance for each injection molding machine.

What do you know about the calculation?

The calculation is not difficult. Similarly, it depends on the product itself and the brand of the base polymer used for its casting. In the initial version, without corrections and coefficients, you can approximately calculate this value.

It is in order to understand how suitable this or that model of plastic injection molding machine for your purposes. You need to multiply the following numbers to get the desired result.

What is the locking force of TPA?

The locking force of the TPA, it is usually prescribed in the passport or product modification.

The pressure of the melt on the walls of the mold:

You can find these numbers in the reference book of polymeric materials. But it is necessary to do this strictly according to the brand. Otherwise, under the same name, substances that are completely different in properties are often found.

Product projection area:

It must be calculated with a high degree of accuracy, because this is the fundamental factor. The calculation must be carried out in the SI system, that is, the area must be calculated in square meters.

The number of seats (cavities) for a specific mold:

We can calculate the calculated area solely by the geometric parameters of the finished product, without unnecessary amendments, which will only complicate the calculations.

For most commercial plastics of common brands, the pressure is no more than 300-400 kg per cm2. High rates are characteristic only of specialized materials with fillers or reinforcement.

Most plastic injection molding machines have long come to the canonical indicator of the clamping force relative to the injection pressure. Usually, the first digit is about 1.17-1.25 times larger than the second. If the number you received lies in this range, then this already means that everything is calculated correctly.

Calculated injection force of plastic mass

Shaping is carried out in a cavity, and the product always has a certain geometric shape and mass, in determining by preliminary calculations. Now a large number of injection molding machines are supplied complete with injection units, but there is always the possibility of compatibility with products from other manufacturers.

This allows assembling systems that strictly meet the technological requirements for the production of a certain type of parts. If selected without calculations, then the volume of the part should be 1.25-1.40 times less than the injection volume.

Total Working Volume of Injection Molding Machine

A useful amendment to this rule is that the total working volume of the plastic injection molding machine should be 3/4 of the indicator useful.

This will significantly extend the service life of the machine during long-term operation as part of continuous production lines. Some models allow the injection and clamping unit to combine into a single module, which saves valuable space in the casting shop.

At the same time, the forces in the clamping units are much greater than in the separate design, it usually exceeds 100 tons, which gives a better result at the output.

Selection according to the correct removal of the product

For this calculation, it is usually necessary to call a specialist in setting up plastic injection molding machine and injection lines. He will be able to determine to what extent the mold opening stroke and ejection depth are sufficient to ensure a successful removal of the finished product.

These are quite complex quantities; you need to be careful when choosing, because most injection molding machines have precise regulation. But working to the limit also discourag due to the too large lever arm formed when opening.

Conclusion

The selection of an injection molding machine is a difficult task that requires the involvement of specialized specialists. Small nuances can significantly complicate or simplify work, reduce or increase productivity. Before choosing, you should always carefully study the characteristics of the equipment.

When selecting, pay attention to the flexibility of using a certain model and modification. One unit will allow you to use a large number of molds. Moreover, it adjusts to the characteristics of the consumer market and profitable highly specialized orders.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2021/12/16

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2021/12/16

- Star Case | Topstar helps Santong upgrade its intelligent plant 2021/12/16

- Topstar Special | National Science and Technology Workers Day 2021/12/16

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC