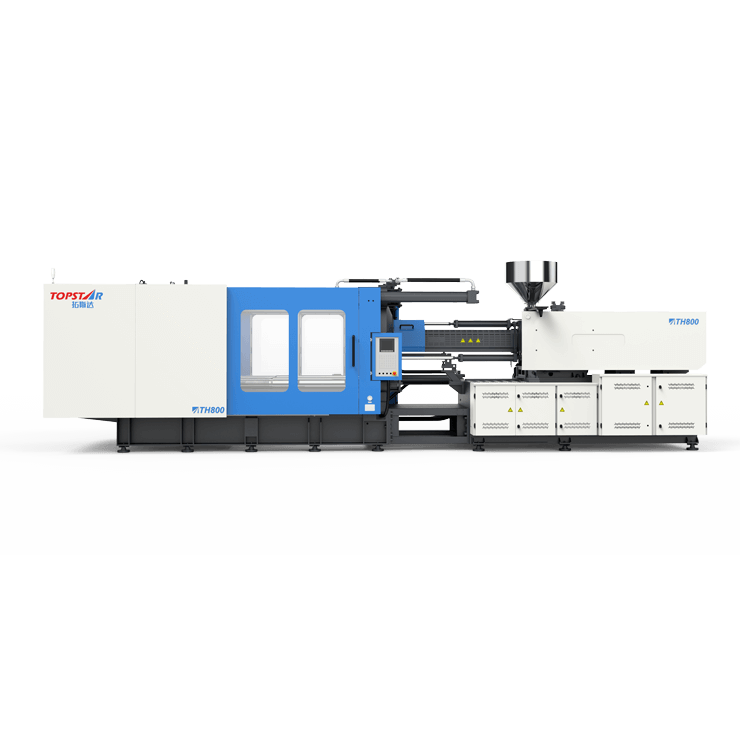

Invest in a Direct Clamp Injection Molding Machine for Your Business

2023/06/19 By Topstar

You know that every dollar counts if you’re a small business owner. This is especially true if you’re trying to grow your business because every investment has to be one that will have a long-term positive effect on your bottom line. So, when it comes to a direct clamp injection molding machine, there are a few things that you need to consider before making the purchase.

We’ll cover some aspects of investing in these machines and how they can help your small business grow, from initial costs and setup expenses to long-term gains in productivity and profitability. By knowing these factors, you can make an informed decision!

A direct clamp injection molding machine will improve your production capacity!

A direct clamp injection molding machine will significantly improve your production capacity. These machines can produce more parts in a shorter time, which means you’ll be able to offer customers a more comprehensive range of products. In addition, direct clamping injection molding machines can produce complex parts.

Direct clamp injection molding is more cost-effective than other methods because it requires less energy and resources than traditional indirect clamps and no additional parts or tooling. This makes direct clamping systems ideal for small businesses looking to save money on their manufacturing processes while still creating high-quality products! The versatility of these machines means they are suitable for various applications.

Direct clamping injection molding machines produce complex parts that typically require outsourcing!

Direct-clamp injection molding machines produce complex parts that typically require outsourcing. They are more expensive, which is worth it if you want something more precise and durable. Direct clamping has other benefits:

Cost-effective: Direct clamps are less expensive because they cost less than the tooling used, so you don’t have to spend as much on maintenance or replacing parts like sprues and cores. Plus, there’s no need for an oven or cooling chamber because this happens inside the machine itself.

Environmentally friendly: Direct clamping involves no toxic chemicals and uses water-based materials. As a result, fewer substances are released into air and water systems than with traditional methods. During the curing cycle, the solvent heats up and evaporates into the surrounding air. To reduce the increased carbon footprint due to the need to maintain a constant high level of energy consumption, the temperature needs to keep the liquid at a specific temperature throughout the production cycle.

A direct clamp injection molding machine is a machine that can produce plastic parts and other materials!

A direct clamp injection molding machine is a machine that can produce plastic parts and other materials. This machine molds plastic parts and produces plastics, such as toys or medical devices.

The direct clamp injection molding machine produces many products, from small medical parts to large toys. The process involves injecting molten plastic into a mold cavity, where the plastic cools and is ejected from the mold. This process makes this method better than traditional injection molding because its operation does not involve consumable tools.

Investing in a direct clamp injection molding machine will allow small businesses to reach new heights regarding quality products!

If you want to improve the quality of your products, investing in a direct clamp injection molding machine will allow small businesses to reach new heights regarding quality products.

Direct clamping is a more precise injection molding method that allows for more precise control over the shape and size of each product. This means that each part will be precisely how its designer intended, ensuring everything fits together perfectly when assembled. It also reduces the possibility of defects in the production process, reducing the number of customer returns.

Direct clamping also makes it easier for manufacturers as they have fewer variables affecting their lines! This saves time, as more periodic adjustments are made after each cycle than with traditional methods.

The direct clamping method creates more repeatability and accuracy in the final product!

Direct clamping is a more cost-effective and efficient method for creating your product. It also has the benefit of producing a higher-quality end product. This makes it an excellent choice for small businesses looking to get started in injection molding.

As we’ve already discussed, direct clamping creates excellent repeatability and accuracy in the end product by allowing you to control every aspect of the manufacturing process. This will help ensure that every part that comes out of your machine meets quality standards, and this higher level of quality will give you more flexibility when pricing your units.

To sum up

If you want to improve your business and make it more competitive, investing in a direct clamp injection molding machine is one of the best ways. It is essential to any manufacturing process as they allow businesses to produce products on demand. Also great for creating what you need when you need it to help you reduce waste. This machine also saves time and money as there are no setup costs to start making parts immediately!

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/06/19

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/06/19

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/06/19

- Topstar Special | National Science and Technology Workers Day 2023/06/19

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC