Innovative technologies from Chinese Injection molding machine manufacturer

2024/02/02 By Topstar

As a manufacturer of complete solutions for injection molding automation, Topstar Technology is ahead of its peers with three core technologies in the era of Industry 4.0. In the following, we will tell you what the core technologies of the injection molding machine manufacturer is in the intelligence era and how. Let the manufacturing industry realize fully automated operations.

Core control system

Control system Compared with the human brain, the control system in injection molding equipment can accurately control the entire equipment. Our robot controller platform integrates motion control, PLC control, and network control. It achieves integrated control with the Topstar injection molding machine controller. The overall process software programming environment complies with the IEC61131-3 international standard, supports EtherCAT, RTEX, MECHATROLINK, CAN, and other industrial bus communication protocols, and integrates a wealth of injection molding industry processes. The package significantly improves the collaborative efficiency of the injection molding machine and the robot. It can adapt to universal six-joint, Delta, SCARA, and non-standard structure robots.

Open servo system

A servo system is a motion control device, including a driver and a motor, that can accurately control mechanical components’ position, orientation, and status. In industrial robots, it is generally installed at the “joints” of the robot. The more joints, the higher the flexibility and accuracy of the robot, and the greater the number of servo systems used.

The five-in-one servo drive system independently developed by Topstar is specially developed for injection molding robot loading and unloading. It realizes a five-axis in-one design and has the characteristics of high integration, small size, low cost, and easy installation. Under normal circumstances, controlling five servo motors requires five servo drives, but we combine five drives into one drive, a five-in-one drive. It is equivalent to one servo driver directly controlling five servo motors, which reduces the overall space, reduces the total cost, and saves space. Successfully solved the problem of finished product deformation caused by collision during automatic mold opening and grabbing of injection molding machines for customers.

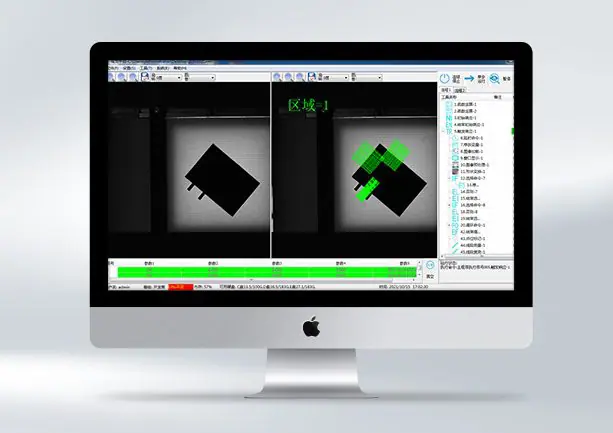

Visual system

Another independently developed vision system can realize positioning, measurement, code reading, OCR, detection, and other functions. The software is simple to operate, uses visual programming, and integrates a wealth of visual operators and logic control tools. At the same time, it supports multi-task and parallel task running modes and full data connection, and it is simple and intuitive. It integrates rich communication functions and supports network ports and port channels. The recognition accuracy is exceptionally high, with the size reaching 0.01 pixels and the angle positioning accuracy reaching 0.01°. Multi-industry applications cover 3C, new energy, optoelectronics, sheet metal, auto parts, and other industries. It supports SCARA, delta, six-axis robots, and other robots.

Core Injection Molding Machines from Injection Molding Machine Manufacturers

“The traditional electric injection molding machine controller will have a communication delay of several milliseconds, resulting in poor quality control during injection molding.” Our customer reported this problem to us that has been bothering him. In response to this problem, we developed the TE II electric injection molding machine and adopted an innovative control method. The intelligent drive control mode reduces the impact of communication delays on the high-speed operation of the servo motor and improves the accuracy of position, speed, and pressure control. , the response speed is increased by 8-16 times. Make injection molding equipment more intelligent to reduce the number of debugging times for production line operators and significantly improve work efficiency.

Injection robots from injection molding machine manufacturers

As an injection molding machine manufacturer with years of industry experience, our injection robot has been updated to the fifth generation. In this generation, the “five-in-one servo-driven manipulator” technology we adopted has achieved precision, energy-saving hardware, and integrated software communication to meet customers’ needs for precision, energy-saving, and intelligence. Through this technology, the removal control is more precise, and the maximum power of each axis is 750W. Improved robot power. At the same time, they have native languages integrated with injection molding auxiliary machines and injection molding machine systems, making equipment interconnection an extension of the system rather than just a communication connection. This solves problems such as failure to take out and equipment alarm shutdown due to ejection position deviation and uncoordinated suction time.

Make industrial manufacturing better

As a Chinese injection molding machine manufacturer, Topstar has achieved synchronization with global standards, so we will continue to provide customers with intelligent manufacturing, energy-saving manufacturing, and other solutions through our innovative technologies. Therefore, as the manufacturing industry develops, we will gradually help companies realize smart factories.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/02/02

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/02/02

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/02/02

- Topstar Special | National Science and Technology Workers Day 2024/02/02

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC