Injection molding robot in the overall solution of injection molding

2024/09/13 By Topstar

In the previous two articles, we introduced the injection molding machine and mold temperature controller in the overall solution of injection molding. The most important automation part in injection molding also includes injection molding robot, which provide higher precision, efficiency and consistency for the production of plastic parts in a range of industries from automobiles to consumer goods, replacing manual labor on the one hand and reducing the defective rate on the other. In this guide, we will explore the key role played by injection molding robots in the overall solution and how they benefit various industries seeking efficient and economical solutions.

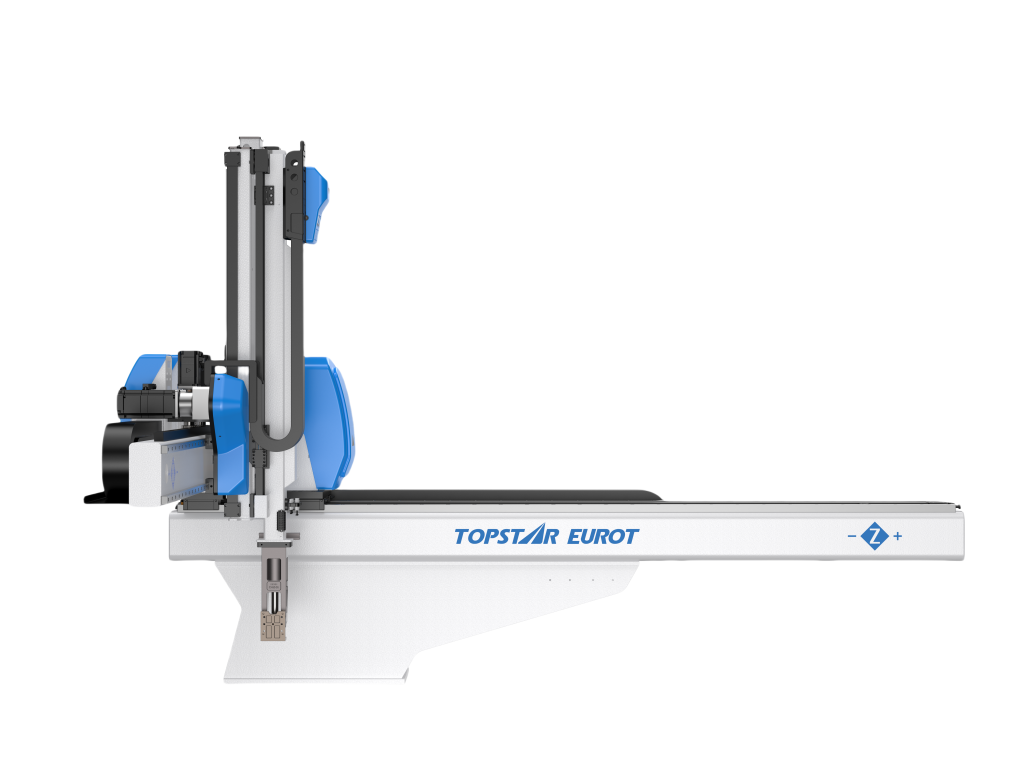

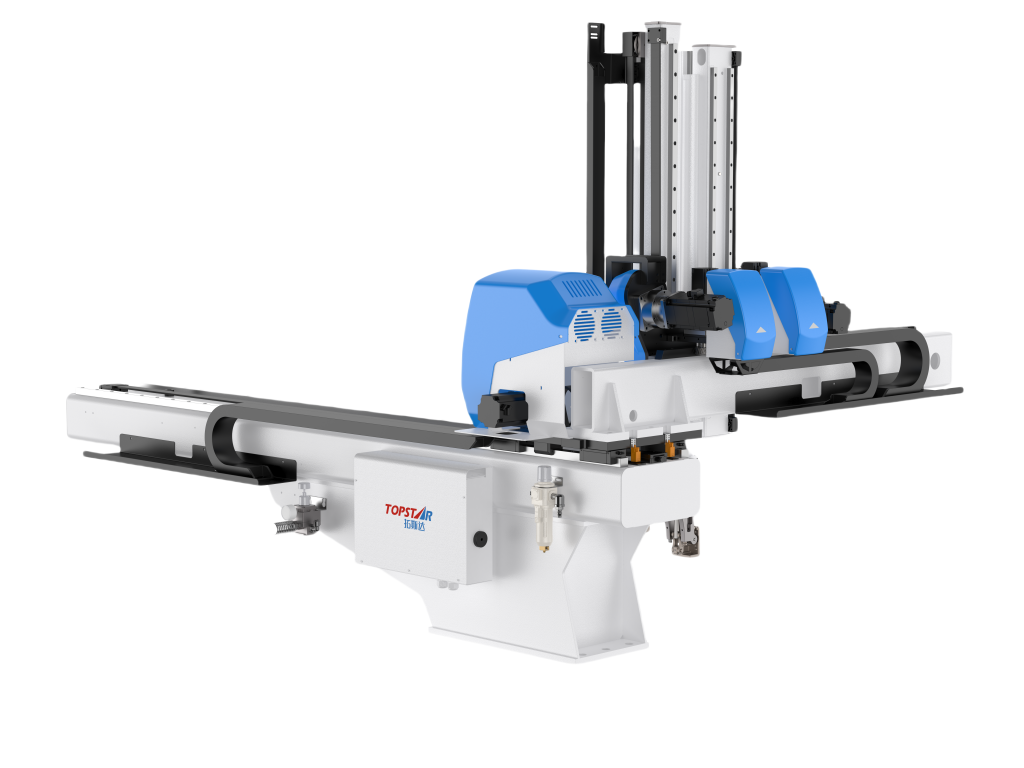

Differences of Topstar injection molding robots

Different from most injection molding robots on the market, their systems are smarter and can support software upgrades and updates through self-developed control systems. At the same time, they support injection molding machines to call injection molding robot signals, integrate linkage, and make control more precise. It also has a built-in dual system, allowing customers to choose freely and program special required actions.

More flexible expansion Fully self-developed five-in-one servo drive, providing powerful algorithms, more precise, more energy-saving and more intelligent. At the same time, advanced injection molding robot motion control technology is also used to ensure that the robot can move smoothly and accurately according to the predetermined contour when executing complex trajectories or paths, thereby improving the production quality and efficiency of the workshop, safer operation protection technology significantly improves the protection ability of the injection molding robot when facing a torque exceeding the set torque, effectively reducing potential damage to customer molds, injection molding machine ejectors and products, and further improving production efficiency and equipment stability.

Intelligent injection molding robot

Make the Topstar injection molding robot more intelligent with the self-developed control system. Unlike standard systems, Topstar’s control system is designed with future scalability in mind. It supports regular software upgrades and updates, allowing customers to access the latest technological advances without replacing hardware. With this feature, manufacturers can easily adapt to changes in production needs or add new features. Including additional features such as better optimization algorithms and more efficient control mechanisms, customers can update their systems accordingly.

Another intelligent aspect is the built-in dual system. This feature enables customers to switch between two different operating systems according to their specific production requirements. This flexibility gives companies the freedom to customize the performance of the robot for other tasks, ensuring the highest efficiency for a variety of applications. The high degree of autonomy in design minimizes the need for constant human supervision. The integration of intelligent control mechanisms also meets real-time monitoring, self-adjustment and troubleshooting functions.

Make injection molding more precise

In order to solve the problem of insufficient precision of the injection molding machine, the Topstar injection molding robot introduces a new vibration suppression function. During the injection molding process, slight movement or vibration of the robot arm can negatively affect the accuracy of part removal, especially in delicate applications such as insert molding. The vibration suppression function works by actively detecting and minimizing unnecessary movements that may occur during operation. Ensure that the robot arm moves smoothly and consistently, even at high speeds, without slight vibrations or oscillations.

Typically, as the speed of the robot increases, the possibility of errors due to uncontrolled movement or vibration also increases. The vibration suppression function solves this challenge, allowing the robot to operate at higher speeds without compromising accuracy.

Reduce overall energy consumption by 10% and save 10% of electricity

Topstar’s injection molding robots can also focus on energy efficiency, which can help manufacturers reduce electricity costs and minimize energy waste. The adoption of Universal DC Bus technology reduces overall energy consumption by 10%, allowing the energy generated during robot movement to be efficiently stored and reused rather than wasted as heat.

The Universal DC Bus system works by sharing power between the robot’s axes, which is transferred to another axis that is accelerating, effectively recovering energy within the system. This continuous flow of power reduces the need for external energy input, thereby reducing power usage by 10%.

Another key feature that helps the Topstar injection molding robot save energy is the Servo Auto-Off feature. This feature allows the robot to automatically shut down when the servo motor is not actively in use. The system turns off the servo motor instead of keeping it in an energy-consuming state, reducing unnecessary power consumption.

Topstar Link Application Platform

One of the most powerful features of the Topstar Link application platform is real-time remote monitoring. This feature allows manufacturers to supervise their injection molding robots from any location. With the platform’s intuitive interface, operators can track the status of multiple machines at the same time and immediately identify any problems when they occur.

In addition, they can also perform equipment operation and data statistics, which can collect and compile comprehensive data on the operating performance of the injection molding robot. The data includes metrics such as cycle time, production output and energy consumption, which are critical to understanding the efficiency and effectiveness of the molding process. Topstar Link also provides data analysis tools to help manufacturers gain deeper insight into their injection molding operations. By analyzing the collected operational data, the platform can provide recommendations to improve efficiency and reduce energy consumption.

Importance to Modern Injection Molding

Injection molding robots are an important part of the overall injection molding solution, making the entire injection molding process more efficient and intelligent. At Topstar, we are more focused on providing complete injection molding solutions that integrate advanced robotic systems tailored to your specific production needs.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/09/13

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/09/13

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/09/13

- Topstar Special | National Science and Technology Workers Day 2024/09/13

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC