What is the Scope of Injection Molding Robot?

2022/04/28 By Topstar

What is plastic injection?

It is generally an industrial process typical of molding plastic and manufacturing consumer parts. An injection molding robot is a high-performance and highly repeatable robot. It ensures the production of many pieces per unit of time.

For this reason, it is one of the most common methods in industries such as the automobile, food, hospital, and pharmaceutical utensils, household items, and kitchenware.

Consequently, automation, specifically the use of robotics in plastic injection, provides greater flexibility and reduced failures. Still ensuring quality and increasing the profitability of each molded part.

Automation in the plastic injection sector

Plastic injection, as well as other molding technologies, are present in many industries. The use of injection molding robots is widespread today. The vast majority of marketed products integrate parts of this material. A good example is the automotive industry, the principal applicant for injected parts, followed by containers and packaging.

These industries have increased their production flexibility and profitability through robotics, automation, and integrating peripherals around injection machines. Also, to achieve a better-quality analysis in 100% of the production and reduce errors.

Based on our experience in injection molding, both assembly lines at the foot of the injector and verification cells at cycle time. It not only helps in terms of productivity and profitability, but injection molding robots also project an image that allows customers to retain and win new projects. With these systems, you guarantee production and quality.

High competitiveness and evolution make the integration of a robot in an injection machine almost mandatory, whether it is a linear robot or a 6-axis robot.

Types of robots for injection molding

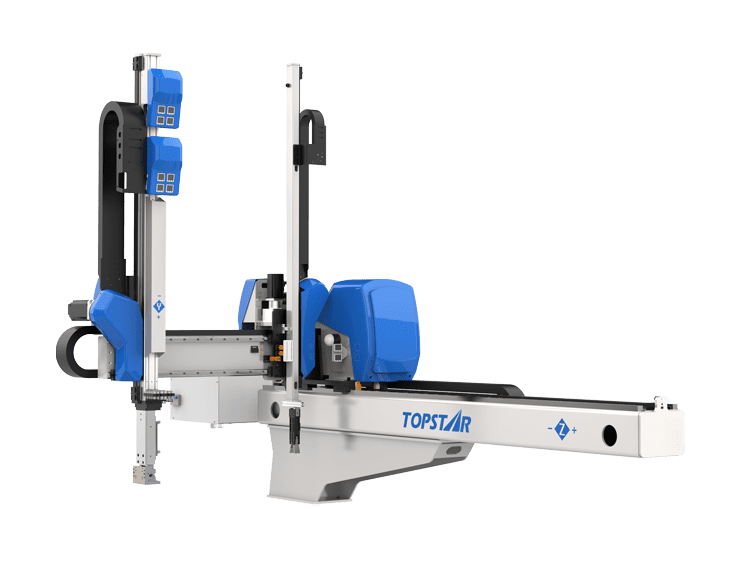

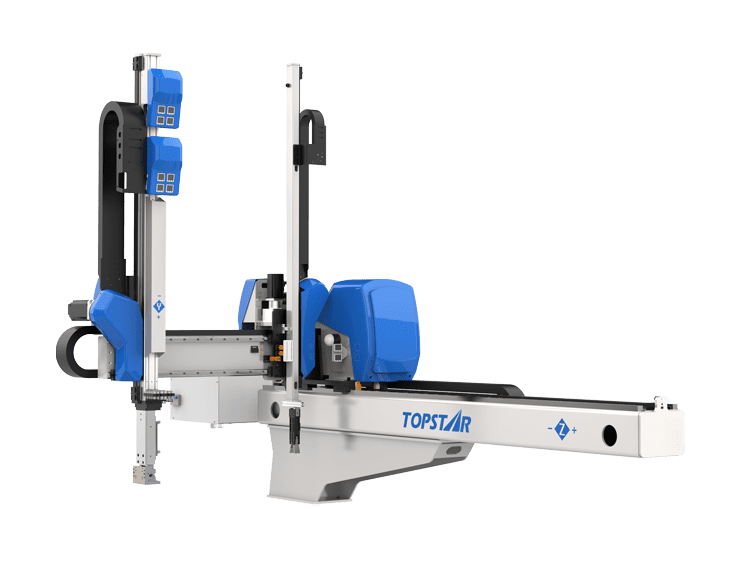

Cartesian:

It is also called “gantry type”; they are the most common to assist injection molding machines. A handy three-axis robot for unloading and repeatable injection cycle movements. They are durable and efficient robots for simple extraction maneuvers from a plastic injector.

A more flexible version is the 3-axis injection molding robot with an articulated wrist. They allow the movement of the wrist activated by a servo at angles from 0º to 90º and from 0º to 180º. The fact that gives these robots a little more flexibility.

Six axes: robot similar to a human arm (anthropomorphic robot) that allows more complex movements for inserting and unloading parts due to the part’s complexity or the mold cavities.

Cobots:

The latest advance and novelty in industry 4.0. They are six-axis robots that stop when they come into contact with a human or another object. Injection molding robot capable of working at maximum speed, reducing it or eliminating it in the presence of a human.

Comparison 6 axes versus Cartesian robot

Complexity in their programming systems: Cartesian robots are more intuitive to configure than a 6-axis robot. The former is specially predesigned for plastic injection; therefore, their control software is designed to be intuitive and visual. In addition, fewer axes have to be moved.

For a 6-axis plastic injection robot, we solve this dilemma by designing a control screen. This way, the maintenance or operator can incorporate new values for specific parameters without touching the console or programming the robot. We also provide training after the start-up.

Molding robot: difference in scope

The main difference lies in this point. An anthropomorphic injection molding robot has more freedom of movement than a Cartesian one. It has 360º rotation and five more axes. At the same time, a Cartesian is limited to vertical and horizontal directions.

These vibrations can compromise the precision typical of these robots. In addition, they are much more helpful at the foot of the injector so that they manage more peripheral processes. Greater flexibility, greater reach, and movement; therefore, better integration with other methods.

Cartesians have an advantage if the available space between machines is scarce. And if height is the determining factor, a 6-axis machine is preferable next to the plastic injection machine.

Injection molding robot: cost and investment

The differences lie in the necessary investment, the space available in the plant, and the operations that can be carried out with each one.

A Cartesian is more affordable than a 6-axis robot that is more flexible and reusable in different projects and processes. A Cartesian robot will be the cheapest option; they also work well when extracting parts. But they fall short when you want to add more functions at the foot of the injector and synchronize them.

Return of investment if you continue to automate processes

For this, in the end, you will have to integrate a six-axis injection molding robot that allows you to expand the range of possibilities. Suppose you intend to automate more and more processes, and initially, you can only install a robot to extract. In that case, we recommend installing a 6-axis since that investment will have a return when you continue to automate more processes and can be expected by integrating other peripheral equipment around it.

Therefore, when calculating the return on investment, it would be necessary to consider the savings in labor, productivity, and reduction of failures due to the successive automated processes. Not only productivity by automating the process of extracting parts from the injection machine.

Operations performed by injection molding robot in plastic injection

Inspection: using peripheral equipment such as artificial vision, the robot can move the piece for its positioning, or it can impact the inspection equipment. As well as feeding and unloading the test bench automatically.

Unloading: this technology is consolidated in the sector for unloading injectors. Especially the use of Cartesian robots, although in recent years, the demand for anthropomorphic robots has grown due to their versatility.

Placement of inserts in the mold: specific components must be introduced into the mold of the injector and thus be integrated into the part. In this operation, six-axis robots that have greater mobility and allow inserting more complex inserts from the side of the fuel transfer machine are very useful.

Injection molding robot: cutting and deburring

Casting cutting by the same robot that extracts the piece, using blades or pneumatic pliers. Likewise, a robot is capable of deburring the parts. In this case, we recommend investing in the improvement or repair of the molds to reduce these failures since the burrs tend to vary in size or position and complicate or make the process more expensive. To remove them.

Handling: the most common operation. The movement of parts between stations or machines.

Packing: for all the packaging subjects and palletizing at the end of the line.

Injection molding with cobots

Currently, the collaborative injection molding robot market has high growth prospects in many industrial sectors and even in non-industrial ones.

These robots have the freedom of movement of an industrial robot. With a risk assessment and the correct security integration, a cobot will assist human operators in your factory without fencing.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/04/28

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/04/28

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/04/28

- Topstar Special | National Science and Technology Workers Day 2022/04/28

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC