The Best Guide to Buying Injection Molding Machines in 2022

2022/02/26 By Topstar

Injection molding machines are essential for mass production in automotive, consumer electronics, packaging, and medical devices. As demand for high-quality, precision-made parts grows, choosing the right injection molding machine becomes even more critical. In 2022, technological advances and evolving manufacturing needs have brought a variety of options to businesses looking to optimize production. In this guide, we’ll cover basic considerations, key features, and tips to help you make an informed decision when purchasing an injection molding machine.

Injection Molding Machines: Understanding Your Injection Molding Production Needs

In 2022, manufacturers are gravitating toward machines that offer flexibility, precision, and efficiency to meet the changing demands for customized products. Considerations include the type of plastic material you plan to use, the complexity of your mold, and production volume. For example, if you plan to produce small, delicate parts for the electronics industry, you’ll need a machine that can precisely control injection speed, temperature, and pressure. Or, if you’re mass-producing more significant parts for the automotive industry, your focus may be durability, cycle time, and energy efficiency.

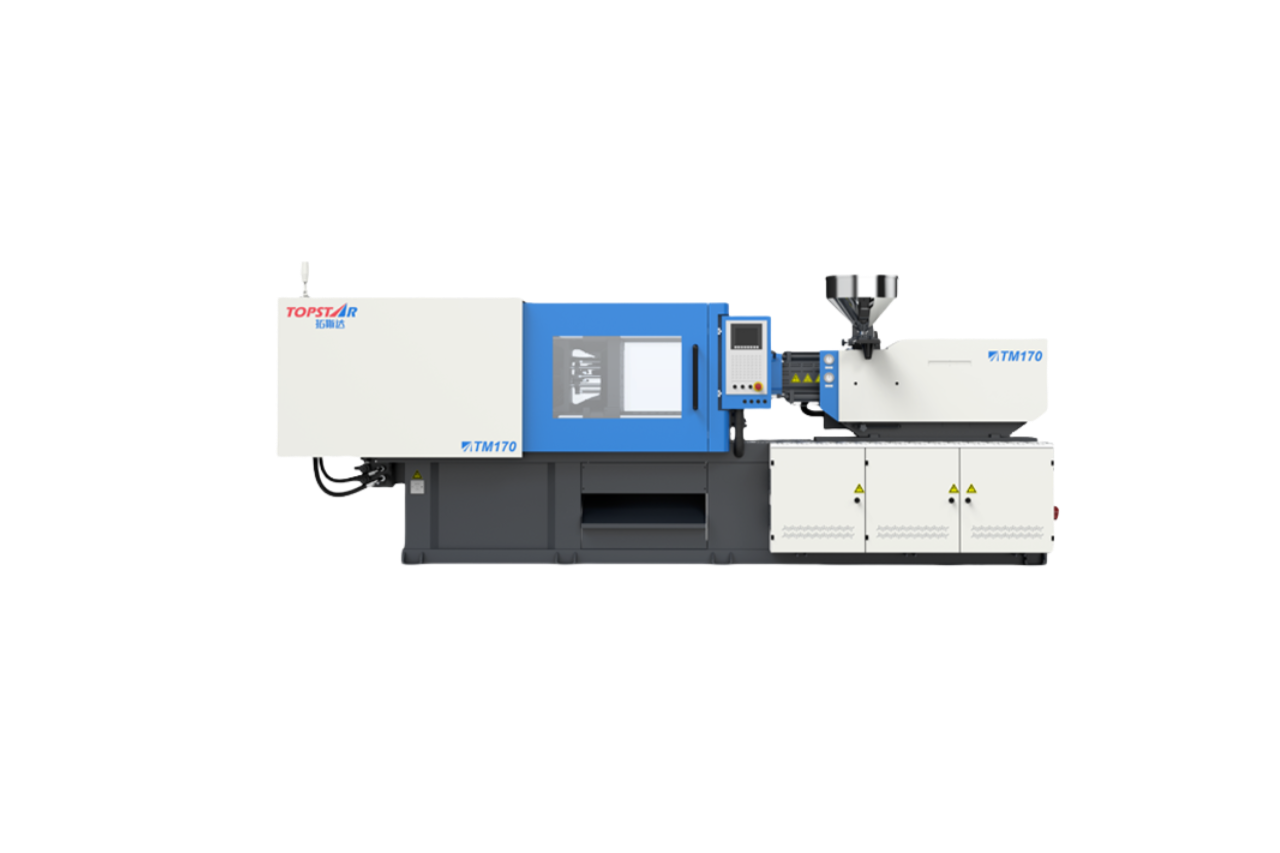

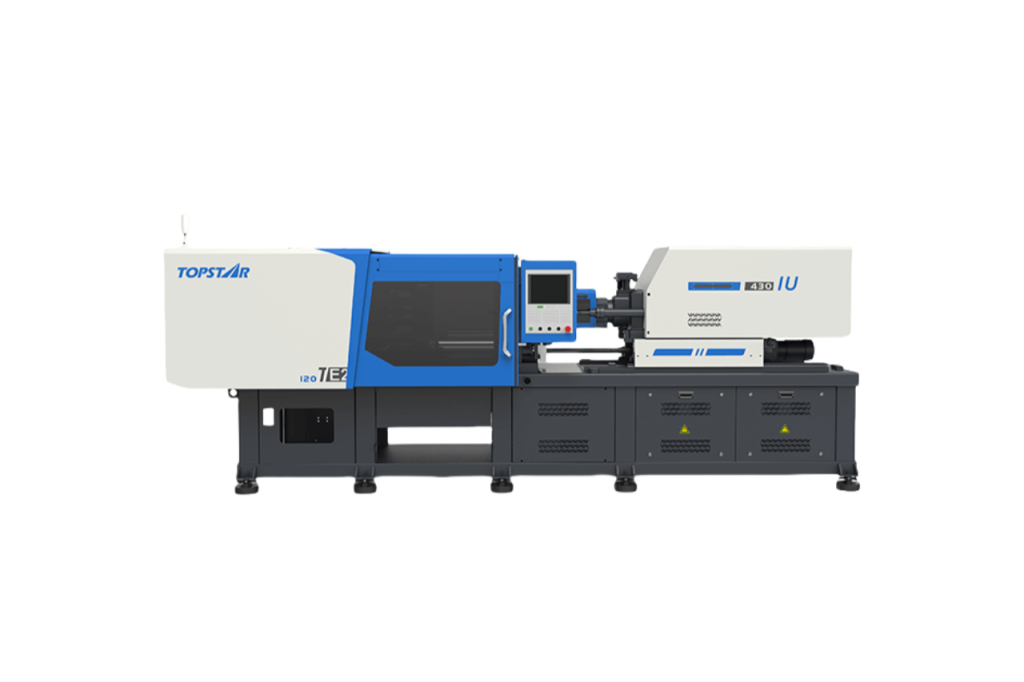

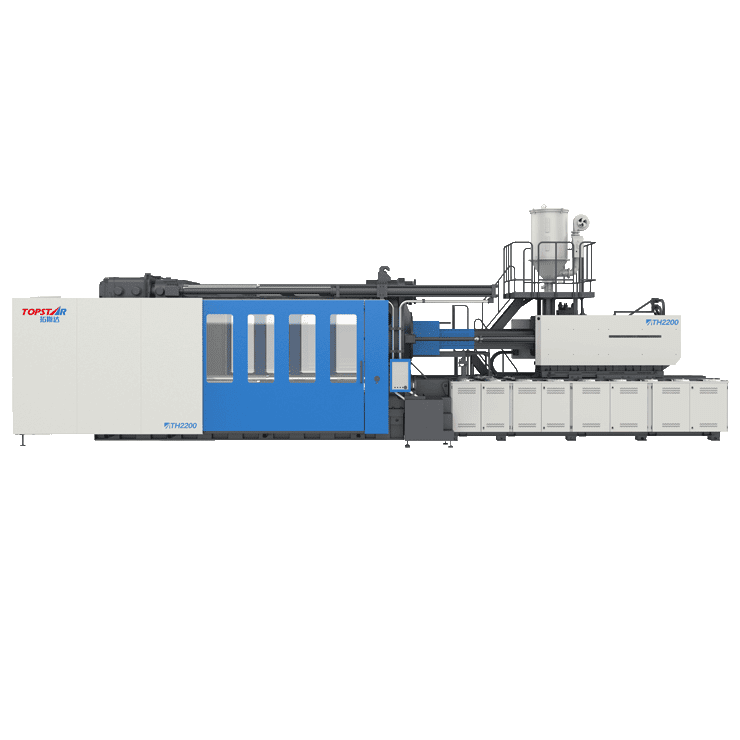

The machine’s size and the injection unit type are also important considerations. Understanding your specific production requirements will help you choose the right size and type of machine, ensuring you don’t spend too much on non-essential features or lack the capabilities required to achieve your production goals.

Key Injection Molding Machine Features to Look For

Several key features can significantly affect performance, efficiency, and product quality when purchasing an injection molding machine. The machine’s overall structure, energy consumption, control systems, and automation capabilities are all key factors to evaluate. In 2022, manufacturers increasingly choose injection molding machines with features that improve precision, energy conservation, and automation.

Non-contact tie rods eliminate friction and wear, allowing the machine to run smoother and more accurately over time. Servo-driven motors are another essential feature that saves energy and controls injection speed more precisely. Closed-loop control systems help maintain consistent production by adjusting real-time parameters, ensuring mold parts are injected at the correct pressure, temperature, and speed.

Energy Efficiency and Cost Considerations for Injection Molding Machines

Energy consumption is one of the manufacturers’ most significant concerns when purchasing an injection molding machine. This energy cost can significantly impact overall production costs, so energy-efficient machines are a wise investment. In 2022, electric injection molding machines have made significant advances that reduce energy consumption without compromising performance. Servo-electric-driven machines are becoming increasingly popular due to their ability to reduce energy consumption. Unlike traditional hydraulically driven machines, servo-electric machines can adjust the power supplied to the injection unit based on demand. This on-demand power supply helps reduce unnecessary energy consumption, making it more environmentally friendly and more cost-effective in the long run.

Choosing the Right Machine Size and Clamping Force

Choosing the right machine size and clamping force is one of the most important factors when purchasing an injection molding machine. Injection molding machines come in a variety of sizes, with clamping forces ranging from small machines exerting only a few tons of force to large machines exerting hundreds of tons of force.

To determine the right size, consider the weight and size of the parts you plan to produce, as well as the size and complexity of the mold. During the injection process, clamping force is required to hold the two halves of the mold together. Machines with insufficient clamping force can result in incomplete or deformed parts, while machines with too much can incur unnecessary costs and energy consumption. In most cases, injection molding machines with clamping forces between 60 and 300 tons are suitable for mid-range applications. In comparison, larger machines of 500 tons or more are ideal for heavy-duty operations in industries such as automotive manufacturing.

Maintenance and Support

The lifespan and reliability of an injection molding machine depend primarily on its maintenance. When purchasing a machine, consider the level of service and support that comes with it. Many manufacturers offer extended warranties, preventive maintenance plans, and on-site support, which can be a significant advantage. Regular maintenance is essential to keep a machine running smoothly, and the complexity of modern injection molding machines means that specific tasks require expertise and tools. Another consideration is ease of maintenance. Machines designed with easy access to key components such as the screw, barrel, and clamping devices make regular maintenance easier, reducing downtime and labor costs.

Making the Right Purchasing Choice for an Injection Molding Machine

Purchasing an injection molding machine is a significant investment that requires careful consideration of various factors, from production needs to energy efficiency and injection molding machine features. In 2022, manufacturers can access more advanced and energy-efficient machines, offering precise control, automation, and cost-saving features that increase production efficiency and product quality. suitable molding injection machine and molds for casting. Again, let’s deliver, set up, and commission injection molding machines. Calculate the required amount of raw materials. Moreover, we professionals can train your technicians. Similarly, they provide warranty and post-warranty support.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/02/26

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/02/26

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/02/26

- Topstar Special | National Science and Technology Workers Day 2022/02/26

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC