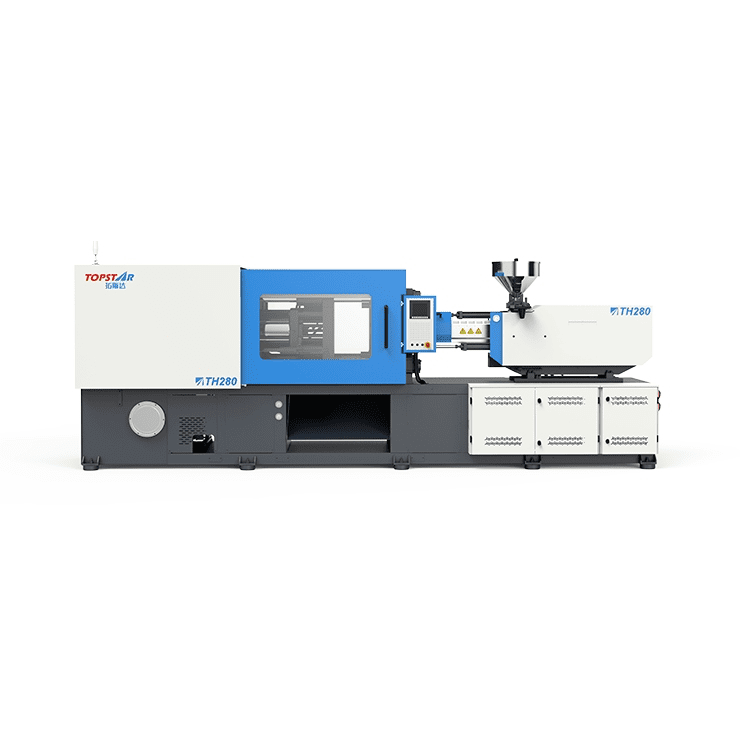

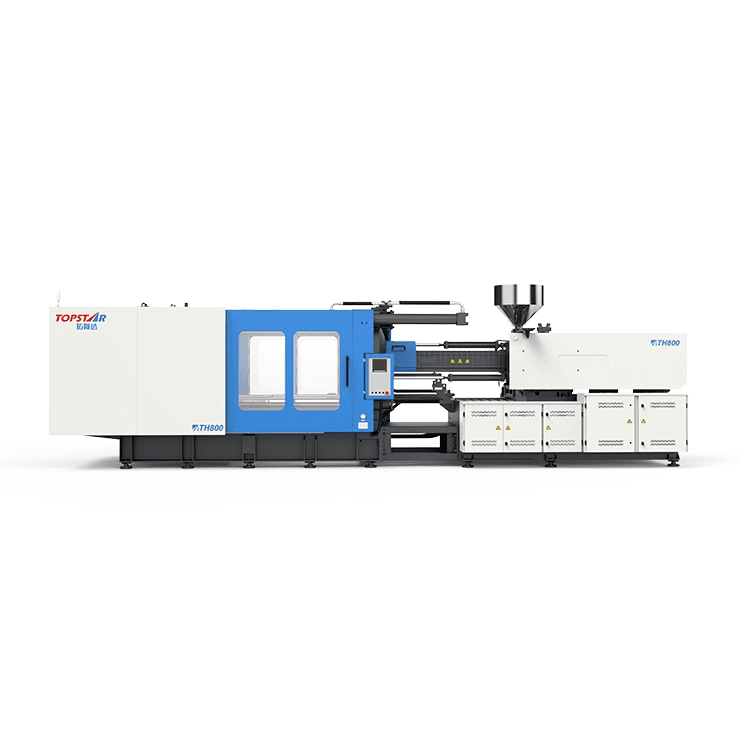

Best injection molding machine for sale at TopStar Machine

2021/12/31 By Topstar

Injection molding machine for sale is of complex design, in which plastics heat and melt to an amorphous state. It follows their transfer to a mold under pressure. Such devices differ in technical characteristics, such as:

- Speed

- casting pressure

- Furthermore, injection volume

- Moreover, plasticizing ability

However, the principle of operation is the same for all injection molding machines.

How to supply raw material under injection molding machine?

Raw materials in the injection molding machine supplies in the form of powder or special granules. Moreover, the main components of thermoplastic devices are:

- Large volume hopper for storage, drying and supply of raw materials to the line. It provides a continuous duty cycle.

- Material cylinder, which consists of two sections. Furthermore, granular plastic enters the loading area, which melts in the working part of this injection molding machine unit

- Auger, with the help of which the molten polymer feeds into the dosing zone

- Similarly, hydraulic motors and hose system to build up the required pressure.

Press form of injection molding machine

Gating channels through which the melted mass enters the mold. Similarly, the locking unit to which the knee belongs is a lever mechanism. In addition, a device that ejects the finished product is also important.

Control electronics

The injection molding machine for sale is one of the most important parts of the injection molding machine. In it, a future product forms from smelted raw materials. The mold consists of a metal plate, on which there is a stationary matrix with a shaping cavity and a punch. According to the pressing method, these parts divide into two types:

- Direct compression molds

- Injection molding molds.

How does the internal mechanism of injection molding machine work?

They differ in the method of pouring molten polymer into the matrix. In a direct compression mold, molten plastic pours directly into a die onto which a punch lowers.

Injection molding machine for sale technology designs to create small batches of products. Moreover, the raw material enters the injection mold through the gating channels.

This method allows the production of plastic products of any shape and size in large volumes. Moreover, molds come on milling machines after detailed design using 3D modeling.

Similarly, molds are easy to install on the injection molding machine, and are also removable. The use of automatic clamps allows you to quickly change shapes, thereby increasing the productivity of the injection molding machine.

Types and stages of manufacturing molds for molding plastics using injection molding machines

Injection molding of plastic products is a technology that makes it possible to obtain parts and products of various shapes and purposes from plastic. This requires an injection molding machine – an injection molding machine and a suitable injection mold for the injection molding machine.

The injection mold of injection molding machine for sale consists of a plate on which there are two main hollow parts inside:

- a stationary die

- a moving punch

They exactly repeat the geometry of future products

The necessary material (polyethylene, polypropylene, polyamide, polycarbonate or other polymers) feds into this mold cavity through special sprues under pressure. Thus, we create a desired shape.

The number of cavities may vary. Molds can be single-cavity (one part is produced per cycle) and multi-cavity (such molds are common to produce a series of several parts).

Also, the mold module supplies with the following parts:

- Bushings and Columns. They center the knot as it closes.

- Ejector pins or pushers (removes finished parts from the mold)

- Backing beams and slabs. Provide the required stroke of the pushers

- Cold runner or hot runner systems. Different sprues are common depending on the type of material.

Types of plastic injection molds

Molds for injection molding machines are automatic and manual, as well as removable and stationary.

They also differ in the pressing technology that is common in a particular production:

Forms of direct pressing: In this case, the molten polymer material enters the matrix. After that, the punch lowers and gives the product the desired shape. Similarly, this method is common to create small batches of plastic products;

Injection molding forms: The molten polymer is poured into a closed injection mold for injection molding machines. This technology is suitable for the production of a large number of products in a variety of sizes and shapes.

There are also two-plate and three-plate forms:

Double plate molds for plastic injection. Similarly, these are cold channel forms that have one parting plane. They are the most common due to their simplicity and common forms. Moreover, we described this structure at the beginning of the article: a fixed die, a movable punch, which fixes on a steel plate.

Three-plate molds for injection molding machines also consist of a non-moving die, but have two movable punches. The second main difference of this type is opening along two planes. One of the planes allows you to extract the finished part, and the other to remove the central sprue. These shapes are needed to create objects of complex geometric shapes.

Hot runner molds for plastic

Their sprues come with heating elements. The design of this type includes an additional set of nozzles and spreading headers, which locate in the matrix array.

In such injection molding machine for sale devices, the material remains hot for a long time and cools down slowly.

Stages of design and manufacture of molds for injection molding machines

The quality of future products depends on the technological process of creating a plastic injection mold and the accuracy of the tooling.

If the technology creates any issue at the manufacturing stage, then you may encounter problems in production. Often, the use of low-quality shapes leads to the fact that products are heterogeneous in structure, cavities or cracks are formed in them, and geometric parameters are violated.

Therefore, it is worth choosing molds that are made in the following stages:

Design: Preparation of a sketch, development of working drawings. During the design process, a 3D model of the future product is created.

Prototyping: At this stage, engineers develop the technology; prepare a prototype of the mold design. At the same time, programmers write a program if the production uses equipment for injection molding of plastics using CNC.

Creation of a mold for an injection molding machine: On special milling machines, the necessary shape parts create from a steel billet. Then they are ground and polished, after which they are assembled into a single whole. An obligatory step is chrome plating of the form. This will increase the wear resistance.

Cooling of castings:

It is an important stage in the mold. Test of form. When all work completes, the plastic injection mold is tested. This stage is easy to carry out in the presence of the customer.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2021/12/31

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2021/12/31

- Star Case | Topstar helps Santong upgrade its intelligent plant 2021/12/31

- Topstar Special | National Science and Technology Workers Day 2021/12/31

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC