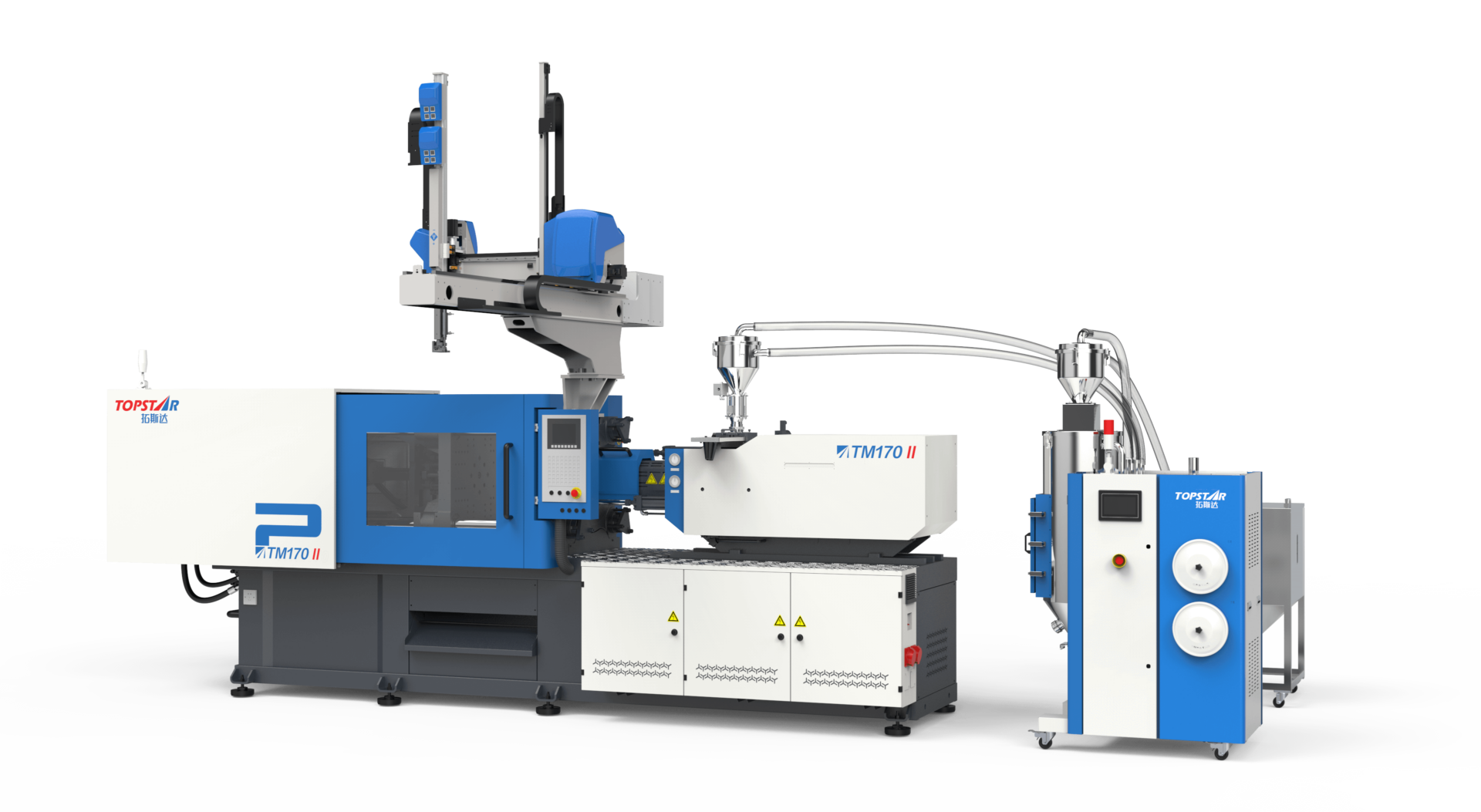

Injection molding machine brand process integrated machine concept

2024/02/07 By Topstar

As China’s largest injection molding machine brand, Topstar has continuously integrated the business, deploying three core products in the injection molding sector: industrial robots, CNC machine tools, and the intelligent environment sector. To figure out what exactly the customer needs? Therefore, we proposed the product concept of an ‘injection molding process all-in-one machine,’ and we will share this concept with you one by one below.

What is an “injection molding process integrated machine”?

The “injection molding process integrated machine” is a multi-technology integration based on Topstar’s various machine technologies. Through our self-developed control system, we can realize communication between the main machine, auxiliary machines, and automation supporting equipment, and the integrated control and hardware concept introduced is also the upgrade of Topstar as an injection molding machine brand enterprise from segmented technology to overall technology. This way, significantly improving broad compatibility, control capabilities, production stability, convenience, etc., will ensure the core of efficient production.

What is its technical principle?

The essential technical difference between it and traditional injection molding machines is understanding equipment intelligence. We define intelligent injection molding machines as integrating software + hardware, which improves equipment intelligence through communication, control, optimization, and perception. Therefore, the technology of process-integrated machines has many intelligent features. Its core is based on integrating software systems to achieve a control interface and linkage with multiple devices, thereby optimizing the entire injection molding process, including injection plastic pre-processing, plasticization, molding control, and the coordination of the removal process. Through system integration, a combination of primary and auxiliary machines, and sensing technology, we can control injection molding factors such as temperature, speed, position, etc.

How does an injection molding machine brand respond to customer needs?

As an injection molding machine brand with many years of experience, we have always emphasized responding to customer needs and creating value for customers. When customers introduce the injection molding process integrated machine, they can solve many production and management problems.

Through integrated control and process linkage, the reduction in the operator’s workload of fine-tuning and monitoring the main and auxiliary equipment, the decrease in labor costs, and the improvement in production efficiency occur. This enables one operator to monitor and fine-tune multiple devices, reducing the manual investment in various devices. After actual customer feedback, the 18 injection molding machines that used to require at least 25 workers now only need 11 workers to complete all the work.

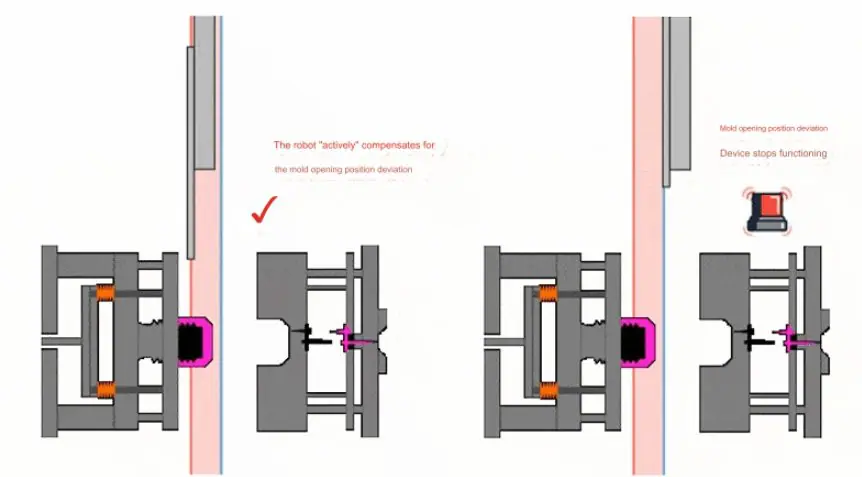

At the same time, it also realizes the synchronous linkage between the robot and the mold opening process. The advanced positioning and precision compensation functions shorten the molding cycle, improving production efficiency. In addition, it adopts an open system, which provides space for equipment expansion and upgrade, making management easier and realizing informatization.

What is the competitive advantage in this industry?

Topstar is an injection molding machine brand focusing on customer production and operation results. Our solution can meet customers’ total production efficiency and management needs. The software system is connected through the injection molding process machine to achieve real-time communication feedback and realize integrated control of the entire injection molding process. Moreover, we have implemented an “injection molding-in-one” design in terms of hardware and precise control of the molding temperature of plastic products in terms of functionality. These technological innovations will bring customers higher production efficiency and quality control levels.

Application of injection molding machine

In the auto parts industry, after our customers used the injection molding process machine, the yield rate reached more than 95%, exceeding the expected 80%. At the same time, the molding cycle was shortened by 16 seconds, and the production efficiency was improved by more than 20%. In the 3C industry, labor costs have been reduced by 50% after customers use the process machine, and production efficiency has increased by more than 40%. These cases show that Topstar can develop and customize solutions and provide effective process machine application solutions for customers in different industries.

The development and future of injection molding machine brands

Topstar’s research and development of injection molding machine processes will continue to adapt to customers’ optimal production ratio and upgrade needs. They will develop process cost reduction, intelligence, modularization, and efficiency. Continuous optimization and refined control of the process can further reduce production costs.

In the future, manufacturers will also design injection molding process machines to be more intelligent, digital, and modular to customize them according to customer needs. Because different industries and applications have additional requirements for process machines, customized designs can meet customers’ specific production needs.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/02/07

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/02/07

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/02/07

- Topstar Special | National Science and Technology Workers Day 2024/02/07

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC