Injection molding equipment suitable for mass production

2024/05/27 By Topstar

Almost all plastic product manufacturers will carry out large-scale production work, so few technologies can match the capabilities of injection molding equipment. These advanced machines have revolutionized the way we manufacture plastic parts. Injection molding equipment actually includes injection molding machines, injection molding robots, injection molding auxiliary equipment, etc. The main core is the injection molding machine. This guide will share why it is suitable for large-scale production tasks.

Basic information about injection molding equipment

The core of injection molding equipment is the injection molding machine, which is a device used to manufacture plastic products. It uses a high-pressure injection to convert plastic raw materials into finished products. The entire process begins with selecting a suitable material, usually a thermoplastic, and heating it to a molten state. This molten material is injected under high pressure into the mold cavity, rapidly cooling and solidifying into the desired shape. The product molds themselves are precision-engineered to replicate the exact specifications of the final product, ensuring consistency and accuracy from batch to batch. From simple plastic toys to complex auto parts, this injection molding equipment can produce large quantities of products efficiently and accurately.

Injection molding equipment suitable for mass production

Topstar’s TMII servo-driven injection molding machine is the most suitable for mass production among the many types of injection molding equipment. The TMII series injection molding machine features a Topstar robot that automatically compensates for the mold opening position of the robot. During high-speed mold opening operation, the injection molding robot can accurately grasp and place parts, making production more stable and efficient. Their high-speed production capabilities enable them to achieve quick turnaround times, ensuring that large quantities of products can be manufactured relatively quickly. They increase overall machine efficiency by 15% and boost servo power by 20%, making them faster and more efficient. Additionally, they integrate closely with robots and auxiliary equipment systems, enabling users to access auxiliary equipment operating data directly on the injection molding machine.

Factors to consider when choosing them

Although the TMII servo-driven injection molding machine is the most suitable injection molding equipment for high-volume production, there are still several factors to consider when choosing. First, the type of material used affects equipment selection, as different materials have different viscosities and flow characteristics. Additionally, the size and complexity of the desired product will determine the specifications of the injection molding machine, including tonnage, clamping force, and shot volume. If the product you are molding is large in size, you will need greater clamping force and tonnage. Other considerations include mold design, cycle time, and overall throughput. These are key to reflecting your production efficiency, and if the equipment is incompatible, it will also lead to low production capacity.

Technological innovation

As industrial technology progresses, the application of system integration technology allows the TMII series injection molding machine to integrate highly with the injection molding robot and auxiliary system. Users can communicate on the injection molding machine through this unified communication language. Directly obtain the operation data of auxiliary equipment, making the operation more convenient. At the same time, we can achieve real-time monitoring and predictive maintenance functions. The innovative use of this technology not only improves productivity and efficiency but also improves safety and reduces downtime.

Cross-industry applications

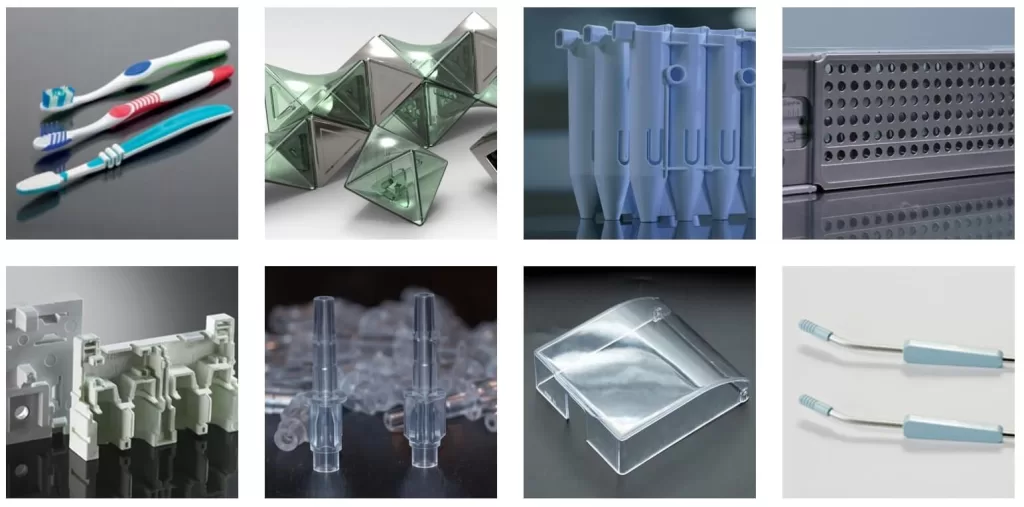

Various industries, including automotive, aerospace, consumer goods, and electronics, widely use them for mass production. The automotive sector is suitable for large-scale manufacturing of all plastic parts, from interior components to exterior body panels to under-hood parts. The electronics industry produces plastic components such as housings and connectors. Even the field of medical optics has specialized equipment to produce surgical instruments, medical devices, and disposable plastics.

Driving efficiency in mass production

Injection molding equipment is the cornerstone of modern plastics manufacturing, capable of mass-producing high-quality products with unparalleled efficiency and precision. The TMII series can be suitable for producing automobiles and electronic consumer goods, and its applications are wide and diverse. At the same time, its communication language also allows operators to control all equipment in a unified manner to achieve higher production efficiency.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/05/27

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/05/27

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/05/27

- Topstar Special | National Science and Technology Workers Day 2024/05/27

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC