How to operate a Plastic injection molding machine in a production line?

2024/01/02 By Topstar

Efficiently operating a plastic injection molding machine is the most fundamental step in ensuring a smooth production process, so how our operators work is crucial. This guide will teach operators the fundamentals of running a plastic injection molding machine in a production line. Learn about their complexities and how to get the best productivity and product quality results.

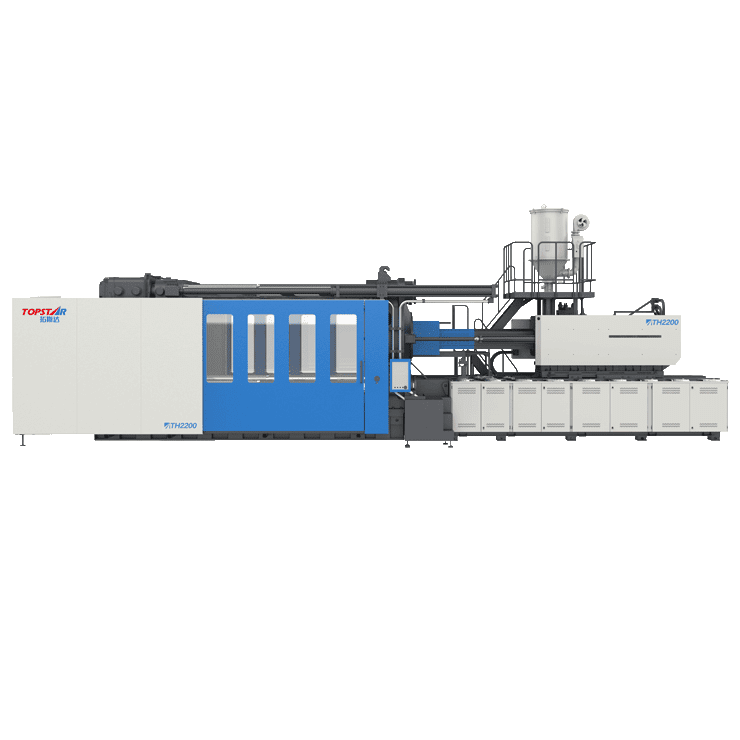

Preparing the Plastic Injection Molding Machine

Before starting production, the plastic injection molding machine needs to be set up correctly. Careful inspection of machine components via a checklist, including cleaning and calibration parameters. Operators should pay close attention to the condition of the mold, carefully observing it to ensure it is free of defects and wear and calibrating parameters such as pressure and injection speed to meet the specific requirements of the plastic material used. Verify that all safety features, such as emergency stop buttons, interlocks, and guards, work. By following a systematic set-up process, you contribute to the final product’s overall quality and the first step of running the machine.

Load raw materials into plastic injection molding machine

First, select the appropriate plastic material based on your production goals and injection molding process. If using plastic pellets, consider utilizing a granulator or grinder to break down the more significant material into smaller, uniformly sized particles. We then use gravimetric devices to measure and control the amount of material loaded into the machine accurately. This increases the accuracy and consistency of the production process. Use material handling equipment such as conveyors, loaders, or hoppers to transport raw materials to the injection molding machine. Efficient drying systems can remove moisture from hygroscopic plastics before loading. Measures can be taken throughout the work process to control dust and contaminants during material handling to avoid contamination.

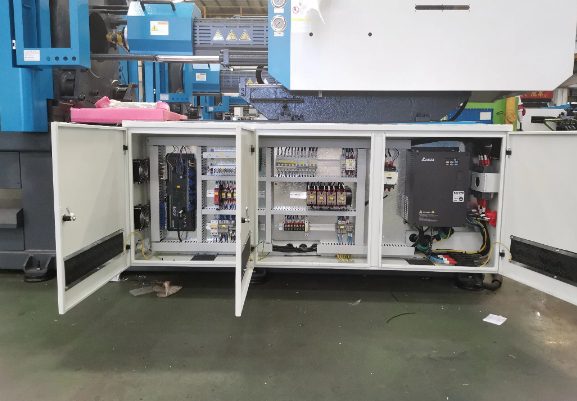

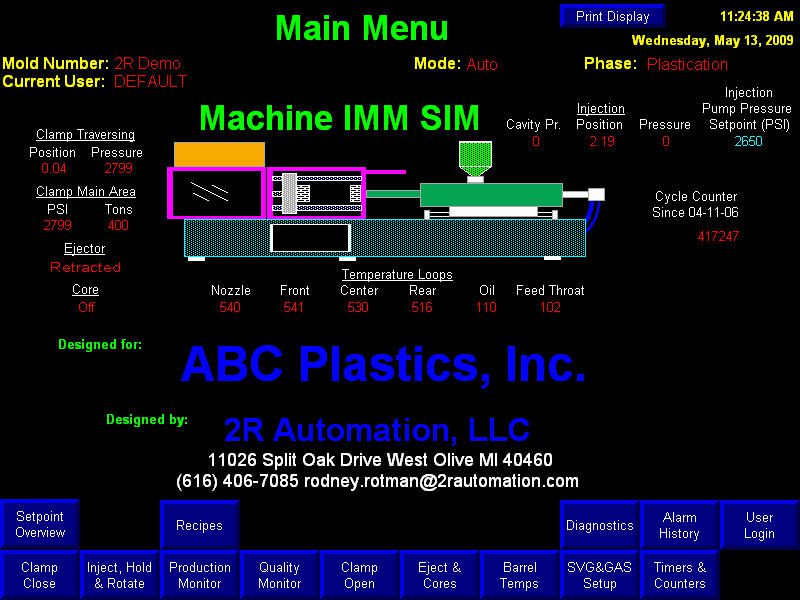

Understand the control interface!

The control panel of a plastic injection molding machine serves as an interface for adjusting various parameters and settings, and the display provides real-time information about machine status, temperature, pressure, and other vital parameters. Operators can monitor ongoing processes and make adjustments as needed. Temperature settings in various areas, including the mold and injection unit, can be adjusted via dedicated controllers. Maintaining precise temperatures is critical to high-quality molding. Operators can adjust injection and holding pressure to optimize molding and prevent defects. Through the control panel, the operator can adjust the duration of each molding cycle, change the injection and having force, control the rotation speed of the screw, and the melting and mixing of the plastic material to optimize production efficiency and meet the required output targets.

Step-by-step operation of plastic injection molding machine

After loading the plastic raw material into the hopper of the injection molding machine, the material is conveyed into a heated barrel where it is melted. Molten plastic is injected into the mold cavity through nozzles and runners. The mold is then closed, holding the mold in place for the injection phase. High pressure forces the molten plastic into complex molds to form the final product. Immediately after injection, a cooling phase begins, allowing the plastic to solidify within the mold. The mold is opened once the part has cooled sufficiently, and the newly formed plastic product is ejected. This cycle is repeated, enabling the mass production of the same product.

Quality assurance

First, start with precision design and mold making. Use CAD tools to create accurate mold specifications. Regularly inspect and maintain molds to prevent wear and ensure dimensional accuracy. Incorporate a thorough inspection process during and after molding. Utilize advanced technologies such as sensors and cameras to identify surface defects, dimensions, and other quality parameters. Sampling and testing are performed regularly to verify product integrity. We also need to train employees to ensure the correct operation and maintenance of injection molding machines and establish a sound quality management system.

Final

Mastering a plastic injection molding machine is something every operator must learn. By following best practices, adopting a proactive maintenance approach, and prioritizing quality assurance, operators can contribute to efficiently operating the plastic injection molding machines in their production lines.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/01/02

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/01/02

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/01/02

- Topstar Special | National Science and Technology Workers Day 2024/01/02

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC