How to Manipulate A Manipulator? 7 Great Ideas

2022/04/28 By Topstar

How to manipulate a manipulator? Currently, modern technologies in production lines have gradually become more popular in enterprises. These devices will help the operating system become more professional, and productivity and product output created simultaneously will be higher than traditional technologies.

In particular, it is necessary to mention injection molding technology in the plastic manufacturing industry. With the application of this technology, it has contributed to improving the efficient processing process for enterprises. The following article will give you an overview of injection molding technology.

How to manipulate a manipulator? What is injection molding?

Injection molding is the name of a technology commonly used today in the manufacturing industry. In essence, injection molding will shape the product through the injection mold system integrated into the injection process.

Moreover, it is mainly used for plastic materials because it is easy to process and requires a high surface gloss to enhance the product’s aesthetic value.

What is injection molding technology?

Injection molding technology is the process of injecting molten plastic into the mold cavity. You can open it when the plastic cools and hardens in the mold. At the same time, push the product out of the mold thanks to the push system. This whole injection molding process does not give any chemical reaction.

How to manipulate a manipulator? Currently, most plastic products use injection molding. This method brings many economic benefits and brand value to businesses. Specifically, injection molding will produce a large number of plastic products with uniform quality.

Moreover, at the same time, these products have high accuracy; the aesthetic value that they bring is always received positively by customers.

Current injection molding technology for plastic materials has gradually replaced Steel, iron, and copper. It can be said that this is a significant change in the manufacturing industry when plastic products have steadily replaced other sources of materials that are gradually depleted in nature.

How to manipulate a manipulator? Therefore, humans have effectively solved the problem of shortage of raw materials and production materials.

At the same time, plastic products using injection molding technology have the same quality as other products because this technology allows you to shape outcomes for even designs with high sophistication and strict requirements for patterns, details, etc.

What is Plastic injection mold?

Injection molding is a type of mold used to shape plastic products. The mold cavity is manufactured based on the available design. Moreover, you can use some specialized software to design the mold cavity: AutoCAD and CATIA.

In addition, each type of mold will have a different structure and size. How to manipulate a manipulator? It will depend entirely on the previous blueprint. You can use many molds for injection molds: 2-plate molds, 3-plate molds, etc.

To successfully manufacture injection molds, the commonly used material is Steel. In general, the standard of a set of molds will include a robust, force-resistant, and heat-resistant mold plate.

At the same time, the details inside the mold cavity need to have high precision with a minimal tolerance ratio. Therefore, depending on the design and production cost, you can choose the appropriate mold steel.

Materials used for injection molding

Currently, the material used for the injection molding process is mainly plastic. How to manipulate a manipulator? This technology allows businesses to flexibly use many different plastic materials: ABS, PP, HDPE, LDPE, etc. Moreover, each type of plastic will have a different melting temperature and technical requirements for the injection molding process. Together.

Therefore, you will need to carefully consider and apply the plastic injection molding process to ensure the working efficiency of the whole production line.

Stages in the plastic product injection molding process

A complete injection molding process will go through 7 steps:

- Prepare materials

- Product injection molding

- Product shaping

- Drag the product

- Check quality

- Scrap handling

- Import

The working principle of an injection molding process is quite simple. How to manipulate a manipulator? When the material is added to the injection molding machine periodically, it will be plasticized. Then, the whole plastic will be filled into the mold cavity and clamped tightly.

Moreover, the primary purpose of this stage is to create and shape the product permanently. You will open the mold to get the product when the plastic has cooled and solidified. The cooling time of plastic will depend on many factors: size, type of material,…

Advanced and modern thermoset plastic injection molding techniques

Thermosetting resins are high-molecular-weight compounds. How to manipulate a manipulator? It can switch to a 3-dimensional state under heat and chemical reactions. This plastic will not be soluble when liquefied and is not renewable. There are many different types of thermosetting plastics: UF, PF, Melamine, …

The thermosetting plastic injection molding technique uses thermosetting plastic for the injection molding process to shape plastic products. In this way, plastic products will have high heat resistance. At the same time, it can effectively insulate and resist deformation.

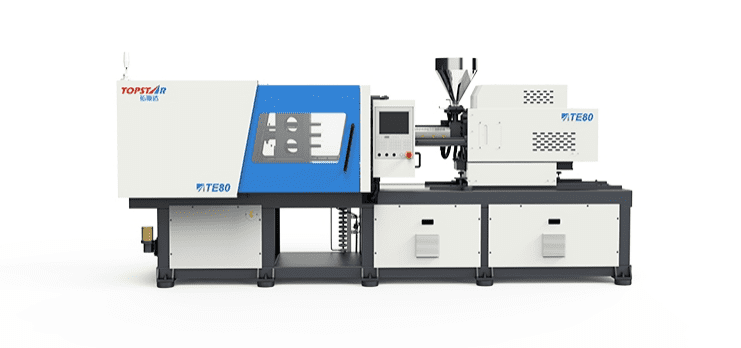

How to manipulate a manipulator? Structure of plastic injection molding machine

Currently, there are many different types of plastic injection molding machines:

- Injection molding machine TM – 250G

- WL1680. injection molding machine

Moreover, each machine type will have its advantages and disadvantages and different uses. But in general, a plastic injection molding machine will include five main details: clamping system, mold system, injection system, injection molding support system, and TLC central control system. In there:

How to manipulate a manipulator?

This is an injection molding machine operating system with four other small systems: body, hydraulic system, electrical system, and cooling system.

Spray system

How to manipulate a manipulator? The main task of the injection system is to put plastic resin into the mold through plastic feeding, compression, degassing, melting, plastic injection, and shaping. An injection system will include:

- Feed Hopper

- Material storage compartment

- Heating tapes

- Screw

- Self-opening regenerator

- Nozzle

The biggest drawback of thermoset plastics is that they cannot be recycled. Therefore, the production of large quantities of thermoset plastic products by injection molding will create a significant impact on the environment. How to manipulate a manipulator? Besides, thermoset plastic will not be safe to use as household plastic objects. The negative impact of plastic may affect the health of users.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/04/28

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/04/28

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/04/28

- Topstar Special | National Science and Technology Workers Day 2022/04/28

HOT TOPIC

- .ervo motor-driven linear robots

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 2

- 21

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 5-axis CNC machine

- 62

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar