How long is the service life of a horizontal injection molding machine?

2023/11/24 By Topstar

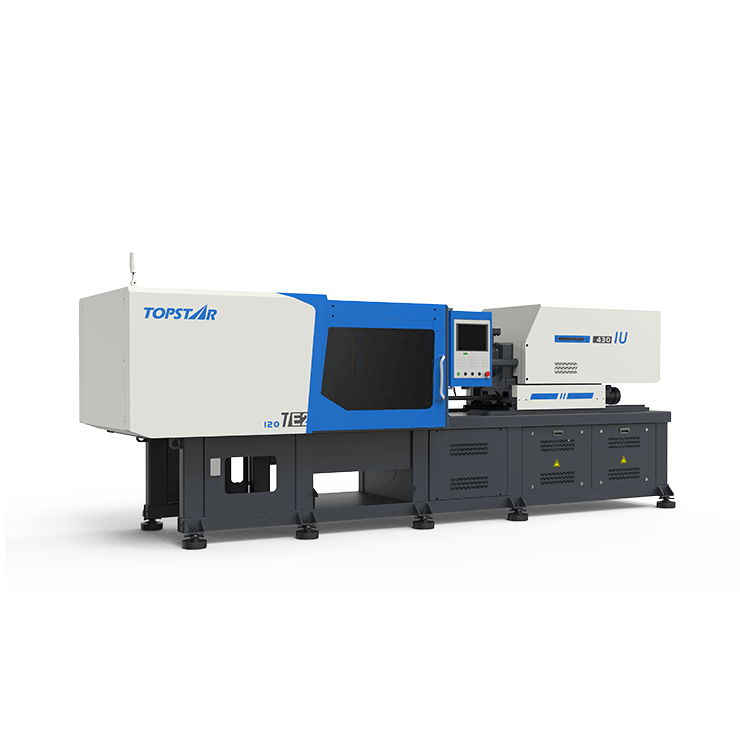

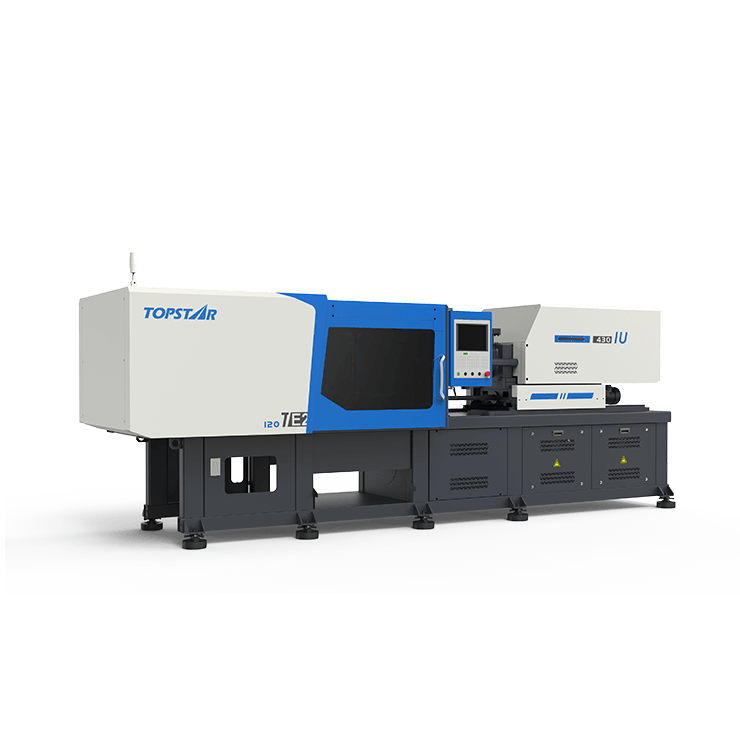

For every plastic manufacturing company, paying attention to the service life of horizontal injection molding machine is essential. Manufacturing bosses, understanding the factors that affect this life span, can play a critical role in optimizing production efficiency and effectively managing costs. In the following, we at Topstar will provide popular science about the service life of horizontal injection molding machine and tell you the key factors that affect their service life.

Service life of horizontal injection molding machine

The service life of a horizontal injection molding machine depends on many factors, including manufacturing quality, maintenance, working environment, and usage methods. Generally speaking, a high-quality horizontal injection molding machine can have a service life of more than 20 years under normal working conditions. Their service life is closely related to operation, environment, and maintenance factors. Each company’s production lines, products, and frequencies differ, so we must maintain and extend their service life according to our conditions. The following section will popularize the factors that affect the service life.

Precautions for operating horizontal injection molding machine

A horizontal injection molding machine’s intensity and frequency primarily affect its service life. Continuous mass production accelerates the wear of critical components and impacts overall performance. Therefore, we must perform regular maintenance to replace parts, correct calibration, and follow the injection molding machine operating instructions. These can all play a good role in mitigating the effects of daily wear and tear. In addition to routine maintenance, it is also critical to implement relevant training for machine operators. Professionally trained operators ensure proper machine use and can identify early signs of wear or potential problems to initiate timely intervention. This proactive approach and regular equipment audits create a symbiotic relationship between operator and machine, resulting in a caring environment contributing to extended service life.

Environmental factor

The operating environment of a horizontal injection molding machine has an indirect impact on its service life. Ambient temperature fluctuations, humidity levels, and contaminant exposure can affect the machine’s service life. To enhance the machine’s ability to cope with environmental challenges, manufacturers must add protective measures such as dust covers, temperature control systems, and air filtration to horizontal injection molding machines. These will help with their longevity. These additions act as a shield, protecting sensitive parts from external factors and reducing the risk of premature wear. Integrating these protection measures into the operating setup can enhance the resiliency of horizontal injection molding machines, ensuring consistent performance over an extended period.

Maintenance strategy

Efficient and timely maintenance is the key to extending the service life of a horizontal injection molding machine, just like you do regular maintenance on your car. From routine inspections to timely problem-solving, our proactive maintenance methods can prevent minor faults from accumulating and eventually developing into significant defects. In addition to regular maintenance, adopting predictive maintenance strategies can revolutionize care. Implementing advanced monitoring technologies like sensors and analytics can assess machine health in real time. Such actions minimize downtime and optimize the overall service life of the horizontal injection molding machine. Machines, like people, need good maintenance and inspection to extend their life.

Material Compatibility for Horizontal Injection Molding Machines

The different materials processed in them exert varying degrees of stress on their components. Incompatibilities between machines and certain materials can accelerate wear and impair performance. In recent years, advances in materials science have led to the introduction of new resins with enhanced properties, providing opportunities to extend the service life of machines. We also need to understand what kind of materials our injection molding machine is suitable for and tell every operator to familiarize them with it. Only suitable injection molding machines with appropriate materials can run well without wear and tear.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/11/24

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/11/24

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/11/24

- Topstar Special | National Science and Technology Workers Day 2023/11/24

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC