How does water quality affect the performance of the mould temperature controller?

2024/12/09 By Topstar

A mould temperature controller maintains precise mould temperature so the injection molding machine can produce high-quality, defect-free products. It regulates mould temperature by delivering water or oil through cooling channels, ensuring stable and efficient production. However, the performance of a mould temperature controller also depends mainly on the water quality used in its system, as water contains higher concentrations of calcium and magnesium ions, which can easily clog water lines. In this guide, we will explore how water quality affects the efficiency, durability, and overall performance of a mould temperature controller and explain how Topstar solves this problem to prevent it from being affected by water quality.

Importance of Water Quality in Mould Temperature Controller

The water used in water-based mould temperature controllers acts as a heat transfer medium, absorbing heat from the mold and carrying it away to maintain optimal temperature levels. If water quality changes, it will affect the ability to accurately and efficiently regulate temperature. Poor water quality can cause problems such as scaling, corrosion, and clogging, which reduces heat transfer efficiency and increases energy consumption. Impurities in the water, including minerals, salts, and dissolved gases, accumulate in the mold temperature controller over time and form deposits on heat exchangers, pipes, and cooling channels, making it more difficult for the water to absorb and dissipate heat effectively. In addition, contaminated water can damage internal components, including pumps, valves, and sensors, leading to increased maintenance costs, frequent failures, and shortened equipment life.

Scaling and mineral deposits in mould temperature controller

Scaling occurs when water contains high concentrations of minerals such as calcium and magnesium, which crystallize and form hard deposits within the water channels of the mould temperature controller. This scaling forms an insulating barrier that hinders effective heat transfer, resulting in more energy consumption to maintain the required mould temperature. These scales restrict water flow, causing overheating, extended cycle times, and increased maintenance costs. Topstar’s pure water series mould temperature controllers come with a water tank, use pure water as the circulating medium, and have a closed circulation system to avoid the corrosion of metal ions on the mold and clog the mold by scale. Reduce the requirements for water quality, prevent mold rust, and ensure cleaner and more efficient operation.

Solve corrosion protection with Teflon float

Corrosion is also a problem in the use of mould temperature controllers. When water contains dissolved gases such as oxygen or carbon dioxide, it corrodes internal components made of metals such as steel or copper, weakens pipes and heat exchangers, and causes system failures and production stoppages. To solve this problem, the closed-loop system design used by Topstar mold temperature controllers minimizes contact with air and reduces the risk of oxidation. In addition, using Teflon floats in these machines ensures high corrosion resistance, even when using poor-quality water containing oil, iron filings, or other contaminants. Topstar precisely manufactures Teflon floats using a zero-welding process, eliminating the possibility of leaks due to welding failures.

A comprehensive solution to the problem of poor water quality and pipe blockage

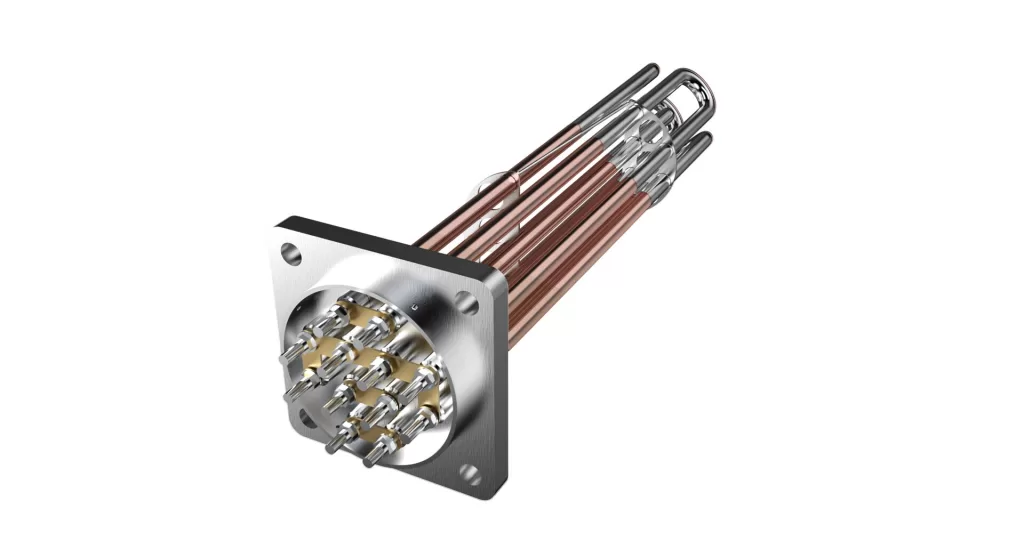

To better solve the problems of poor water quality and pipe blockage, Topstar has upgraded the copper heater on the water-type mould temperature controller. People know copper for its excellent ductility and thermal conductivity, which minimize the adhesion of water-borne particles and maintain the integrity of the heating element. As a result, you can increase the life span by 40% and the efficiency by 10%. You can also use it normally even when the water quality is poor.

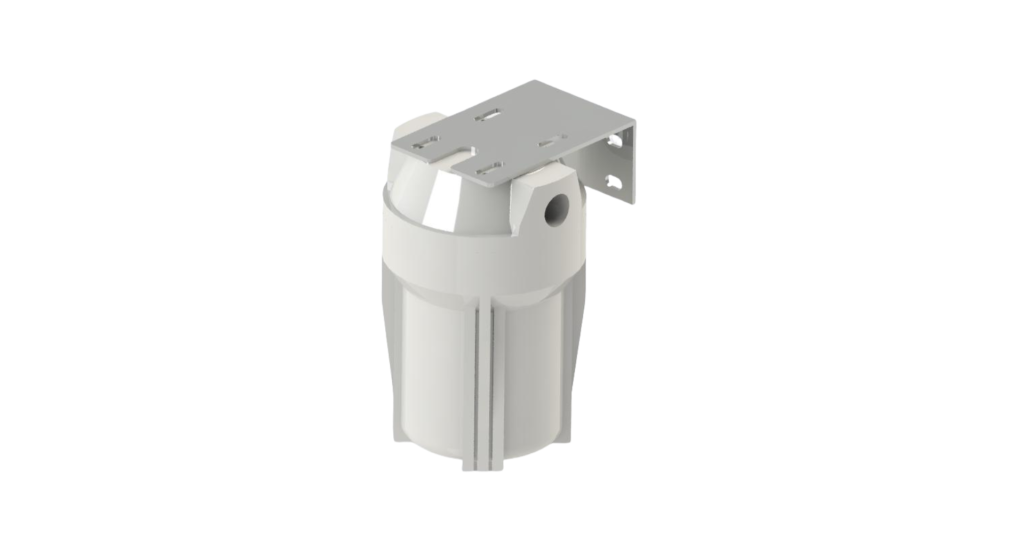

In addition to the copper heater, Topstar also equipped the mold temperature controller with a standard 50 mesh high-precision filtration system, which further solves the problem of impurities in the water. It can capture larger particles and prevent debris from accumulating in the system. For environments with particularly poor water quality, we offer an optional 30μm filtration grade precision filter with a filtration pore size of approximately 0.03 mm – equivalent to the diameter of a human hair. This ultra-fine filtration prevents even the smallest particles from entering the system, preventing mould clogging and ensuring the water flow remains uninterrupted and clean.

No longer affected by poor water quality

Poor water quality will directly affect the mould temperature controller’s performance, efficiency, and life. Contamination can be prevented by adopting Teflon material floats, pure water circulation systems, closed-loop designs, and upgrading copper heaters and high-precision filtration systems, and maintenance needs can be minimized.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/12/09

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/12/09

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/12/09

- Topstar Special | National Science and Technology Workers Day 2024/12/09

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC