How do you avoid mold sticking problems in injection molding machines production?

2025/02/03 By Topstar

Injection molding machines enable precise batch production of plastic parts in the production of plastic products. However, one problem that often plagues operators of actual output is mold sticking. That is molded parts stick to the mold cavity or core during the ejection process. This problem not only affects production efficiency but also increases scrap rate and maintenance costs. Therefore, solving the problem of mold sticking is crucial to providing consistent product quality. In this guide, we will explore several possible strategies to prevent mold sticking problems, emphasizing best practices for optimizing injection molding machine performance.

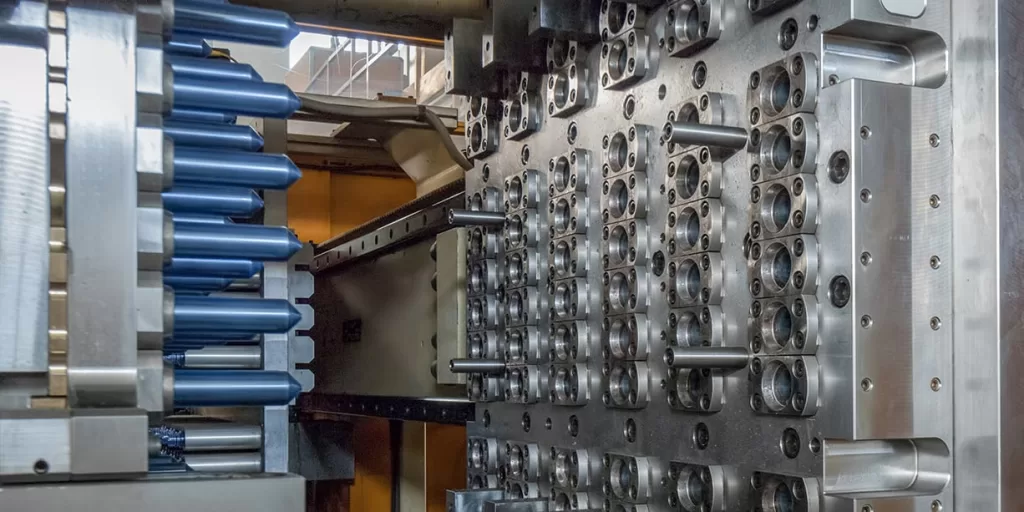

Optimizing injection molding machines mold design to prevent mold from sticking

A well-designed mold is the first line of defense against mold sticking problems. Injection molding machines rely on molds with precise geometry, surface finish, and cooling systems to ensure smooth part release. For example, an insufficient draft angle (taper applied to vertical walls) can create suction that pulls the part back into the mold. Topstar recommends a minimum draft angle of 1–3°, depending on the material type and part complexity.

In addition, polishing the mold surface reduces friction, while textured finishes may inadvertently trap molten resin. Proper venting is equally essential – trapped air or gas can increase internal pressure and cause parts to stick. Topstar’s injection molding machines use a self-developed control system that monitors mold conditions in real-time, enabling pressure and temperature adjustments before sticking occurs.

Control injection molding machine temperature settings

Poor temperature management is the leading cause of mold sticking. Injection molding machines must maintain precise thermal control of the barrel, nozzle, and mold. Overheating the molten plastic can degrade the material and produce a sticky residue that sticks to the mold. Conversely, low temperatures can cause incomplete filling or premature cooling, which increases ejection resistance.

For temperature control, Topstar’s fourth-generation mold temperature controller can ensure an accuracy of ±1°C. For example, semi-crystalline materials such as polypropylene require higher mold temperatures (40-80°C) to minimize shrinkage and sticking, while non-crystalline plastics such as ABS perform best at 50-70°C. Calibrate thermocouples regularly and use thermal imaging cameras to identify hot/cold spots in the mold.

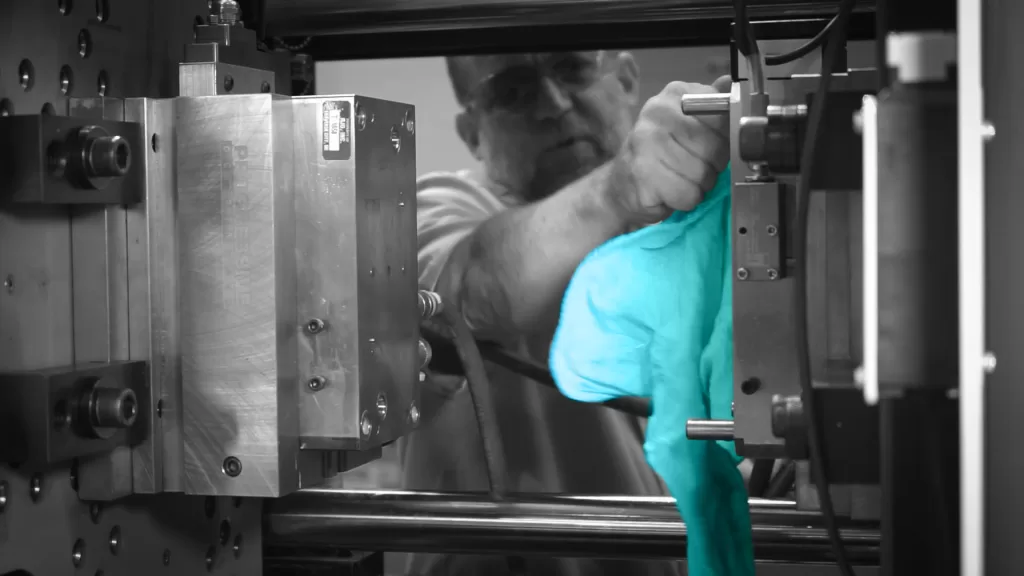

Fine-tune ejection parameters

Ejection force and time are key to avoiding sticking. Too fast an ejector speed or a misaligned ejector pin can deform the part or damage the mold. The injection molding machine must synchronize ejection with the cooling phase – too early ejection risks tearing, while a late ejection causes the part to shrink and seize the mold.

Topstar’s servo-driven ejection system allows programmable force distribution, which reduces stress on delicate components. For example, a two-stage ejection process (gentle initial movement followed by full retraction) minimizes sticking in deep-cavity molds.

Choosing compatible materials

Material properties directly influence the risk of sticking. Hygroscopic resins absorb water, leading to gas formation and sticking. High-viscosity materials, such as polycarbonate, require higher injection pressures, which increase friction.

Topstar’s injection molding machines support a material database that automatically adjusts settings for optimal flow and cooling. For example, adding 0.1-0.5% lubricant to polyolefins can significantly reduce sticking. In addition, always dry hygroscopic materials to ASTM standards before processing.

Keeping injection molds clean

Contamination is the main culprit for sticking. Dust, degraded resin, or residual release agent can cause uneven surfaces that trap molten plastic. While making suitable equipment parameter adjustments, Topstar also emphasizes daily cleaning procedures for injection molding machines, including cleaning the barrel with a specialized cleaner before changing materials. Mold maintenance is equally important. Ultrasonic cleaning can remove microscopic debris on textured surfaces, while laser ablation can repair pits or corrosion. Implement a preventive maintenance plan to replace worn parts, such as springs or bushings, which will cause the ejector mechanism to misalign if not replaced in time.

Better Solutions for Sticking Problems

By optimizing mold design, temperature control, ejection system and material selection, Topstar can help customers achieve perfect production operations. Remember, every minute saved in solving sticking problems means higher profitability and customer satisfaction.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/02/03

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2025/02/03

- Star Case | Topstar helps Santong upgrade its intelligent plant 2025/02/03

- Topstar Special | National Science and Technology Workers Day 2025/02/03

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC