How do injection molding machine manufacturers help smart manufacturing?

2024/11/08 By Topstar

Intelligent manufacturing uses data, automation and digital technology to optimize production and improve efficiency, thus changing the global manufacturing industry. Under the influence of worldwide digitalization and intelligence, as injection molding machine manufacturers, we have received feedback from many customers and collected specific smart equipment requirements from clients in different countries and regions. These requirements include whether it is possible to monitor abnormal changes in auxiliary machine data and give early warnings; whether it is possible to monitor auxiliary machine alarms and actively shut down when unattended to reduce defective products; and whether there is a compensation solution for optimizing inaccurate mold positioning, how to shorten the removal time and improve overall efficiency, etc.

Injection molding integrated production with injection molding machine manufacturers

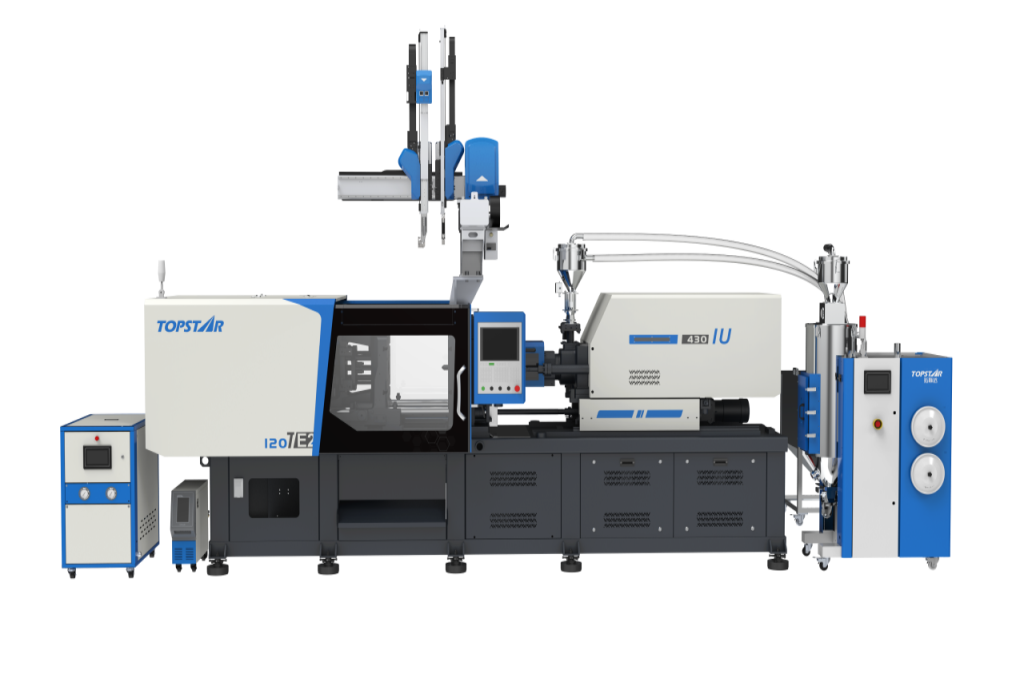

Automation is the basis of intelligent manufacturing. On this basis, Topstar, as an injection molding machine manufacturer, has proposed an “injection molding process integrated machine” in this field. We have observed that when workers adjust the mold temperature controller and the injection molding machine, they often need to go back and forth repeatedly, and adjusting parameters is cumbersome and complicated. Sometimes, due to untimely adjustments, the injection molding machine alarms abnormally. Therefore, to solve these problems, the “injection molding process integrated machine” was developed under the Topstar self-developed system, integrating the signals of the injection molding machine, auxiliary machine and automation and supporting the call and control by the host controller. It avoids frequent equipment debugging, improves operational efficiency, and makes injection molding production smarter.

Topstar focuses on sectors such as new energy, auto parts, and biomedicine to make more customers in different regions and countries and different industries feel intelligent. The injection molding machines with the integrated injection molding process will continue to be optimized and upgraded, and the hydraulic presses will increase R&D investment in special machines in the subdivided fields to provide dedicated intelligent injection molding solutions for different customers.

Achieve data-driven production together

Data is the core of intelligent manufacturing, enabling manufacturers in various industries to make informed decisions and optimize processes in real-time. We integrate different sensors and data collection functions into a control panel in the injection molding machine, allowing operators to monitor critical indicators such as temperature, pressure, cycle time, and material flow. Operators can make data-driven adjustments to improve product quality and reduce waste by providing equipment to collect and analyze data. In addition, cloud-based software and data platforms are provided for storing, analyzing, and visualizing collected data. This data enables production teams to identify patterns, solve problems, and prevent problems before they occur.

Injection molding machine manufacturers realize intelligent injection molding production environment

Different from the energy management of traditional factories, Topstar intelligent whole factory planning will provide consulting services in the early stage. It will investigate site layout, equipment and automation selection, production capacity requirements, labor requirements, organizational structure, cost-effectiveness and production safety, and comprehensively consider module energy’s dynamic demand and environmental protection requirements. Discuss the ideal production model with customers, use digital simulation technology to formulate standardized modules, optimize construction coordination, and achieve rapid implementation. As a customer-centric injection molding machine manufacturer, it can help customers avoid risks and apply BIM visualization and rapid construction technology to realize the intelligent environment of customer factories.

1-1024x682.webp)

Upgrade intelligent equipment

Topstar’s open control system design can meet the upgrade needs of customers’ applications. Hardware equipment with core technology can meet the perception capabilities in communication, compatibility, data acquisition, etc. This is an essential difference between intelligent and traditional equipment, which is also the basis of smart production. By developing independent control systems, servo drives, and underlying visual algorithm technologies, the host equipment upgrades are more flexible, compatible, and suitable for intelligent interconnection needs. At the same time, in the process of integrated injection molding processes, innovations such as precision complementarity, process linkage, and integrated control are achieved, allowing customers to operate, repair, and debug more simply.

Production line automation

Standardized process production management is the key to achieving production line automation. Using standardized production process management, we will upgrade injection molding machines and industrial robots with collaborative, communication, and perception capabilities to automate production lines according to actual customer needs, improve manufacturing consistency and stability, increase yield, and reduce production costs, ultimately achieving lean, intelligent, and automated manufacturing goals.

Achieve intelligent production in multiple industries

Topstar is an injection molding machine manufacturer with three major intelligent equipment as the core. It provides small- and medium-sized injection molding companies with intelligent whole-plant solutions that meet the upgrade needs of different stages. It also provides customers with water, electricity, gas, and gas systems, central feeding systems, and dust-free workshop whole-plant planning. Using injection molding robots and mold temperature controllers can save a lot of human resources, increase speed, significantly improve efficiency and become more intelligent.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/11/08

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/11/08

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/11/08

- Topstar Special | National Science and Technology Workers Day 2024/11/08

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC