How can phone case maker machine improve traditional production processes?

2024/12/04 By Topstar

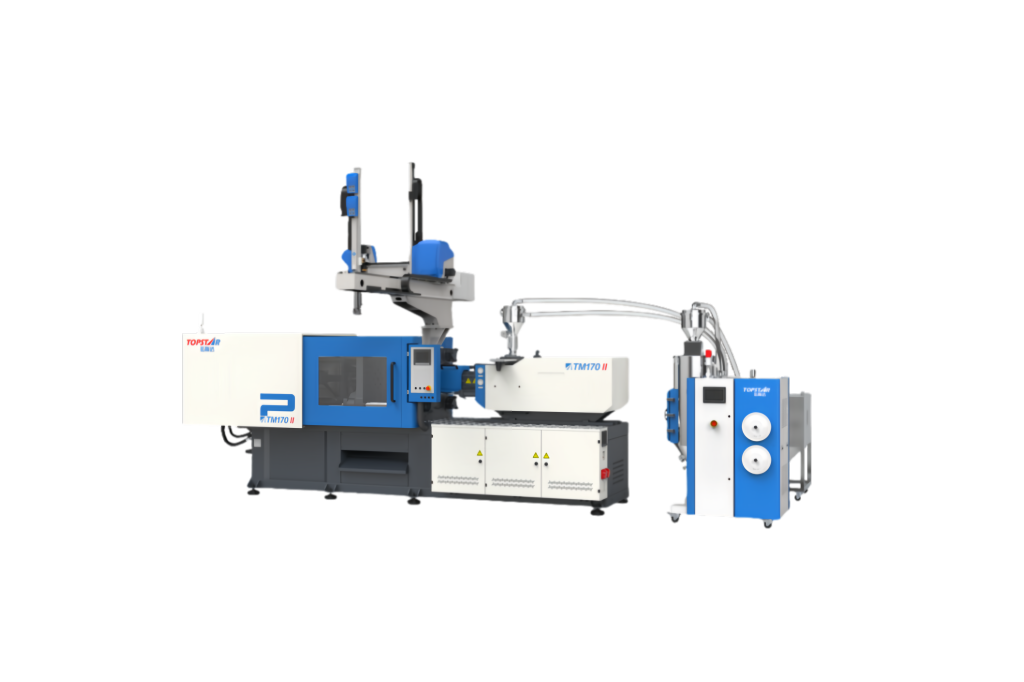

Injection molding is one of the leading manufacturing processes for producing plastic phone cases. Traditional injection molding has served these companies well over the past few decades. However, as consumer demand for high-quality, durable, and aesthetically pleasing mobile phone accessories grows, plastic phone case manufacturers need to find ways to optimize production and improve molding efficiency and quality. Topstar can provide exclusive injection molding solutions for customers with different materials and quality requirements. The core phone case maker machine solves the shortcomings of traditional production. Therefore, this blog post will explore how they improve conventional injection molding production.

Phone case maker machine optimization to improve production speed

Traditional mobile phone case manufacturing machines must be faster in production, resulting in longer delivery time and slower output speed, affecting product delivery date. Topstar’s phone case maker machine uses electroplated screws and temperature-controlled unloading to make production more efficient and make the application range of the rubber more comprehensive. In addition, oblique double-shot cylinders and linear guides are also used to make the injection more accurate and stable. By upgrading the two hardware systems, they can produce mobile phone cases at a much higher speed than traditional systems, increasing production and speeding up and enabling manufacturers to take on more orders.

Improve precision and quality control.

Achieving quality consistency across all units in traditional injection molding is difficult. Because it is difficult to control temperature and pressure uniformly, slight changes in these parameter settings may lead to warping, misalignment, or surface defects. This affects the beauty of the mobile phone case and the function and durability of the final product. To improve product precision, Topstar uses proportional back pressure control in pressure control, making operation simple and achieving multi-stage back pressure settings, improving the injection precision and plasticization quality of the phone case maker machine. Regarding temperature control, the mobile phone case manufacturing machine can be integrated with the mold temperature controller. The PID temperature control algorithm of the mold temperature controller improves temperature control efficiency by 10%, ensures temperature uniformity, maintains consistent quality and precision, and reduces rework time.

Reduce material waste in the injection molding process.

Traditional injection molding processes usually generate a lot of material waste because manufacturers use excessive amounts of plastic and other resources in the production process.

Reduce labor costs and improve operational efficiency.

Labor costs are essential for any manufacturing company, especially in regions such as the United States, where labor costs are high. Traditional injection molding systems usually require manual labor for machine setting, monitoring, quality control, and material handling tasks. This increases the overall production cost, quickly leads to human errors, and affects production efficiency. The concept of “injection molding process integration” is adopted in the phone case maker machine developed by Topstar, and the parameter setting and working condition monitoring of all peripheral equipment are integrated into the machine controller, reducing the need for labor and enabling manufacturers to streamline labor. As a result, tasks such as material loading, mold handling, and part ejection can be handled with almost no human intervention. This can reduce labor costs, improve the safety of production workshops, and improve operational efficiency.

Improve scalability and meet market demands with phone case maker machine.

Market trends for mobile phone accessories are rising as demand continues, and mobile phone case manufacturers are also expanding production to meet these demands. Traditional injection molding systems often limit companies when scaling up or down production. Conventional systems may lack flexibility if a company needs to increase production during the peak season or reduce it in the off-season. Topstar designs its phone case making machines with scalability in mind. Its modular design enables manufacturers to scale up quickly or down production based on demand. By adding more machines or adjusting settings within existing systems, companies can increase production capacity during periods of high demand. At the same time, the one-key mold adjustment function adopted can achieve a one-key automatic mold adjustment function, reduce mold change time, and improve production efficiency.

More efficient injection molding production

From improving production speed and accuracy to reducing material waste and labor costs, phone case making machines enhance every stage of the manufacturing process. Topstar’s ability to provide customization, scalability, and greater operational efficiency enables manufacturers to remain competitive in a rapidly evolving industry. By adopting Topstar’s phone case making machines, manufacturers can increase productivity and meet consumer needs more effectively.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/12/04

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/12/04

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/12/04

- Topstar Special | National Science and Technology Workers Day 2024/12/04

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC