What is home injection molding machine? Best Guide 2022

2021/12/31 By Topstar

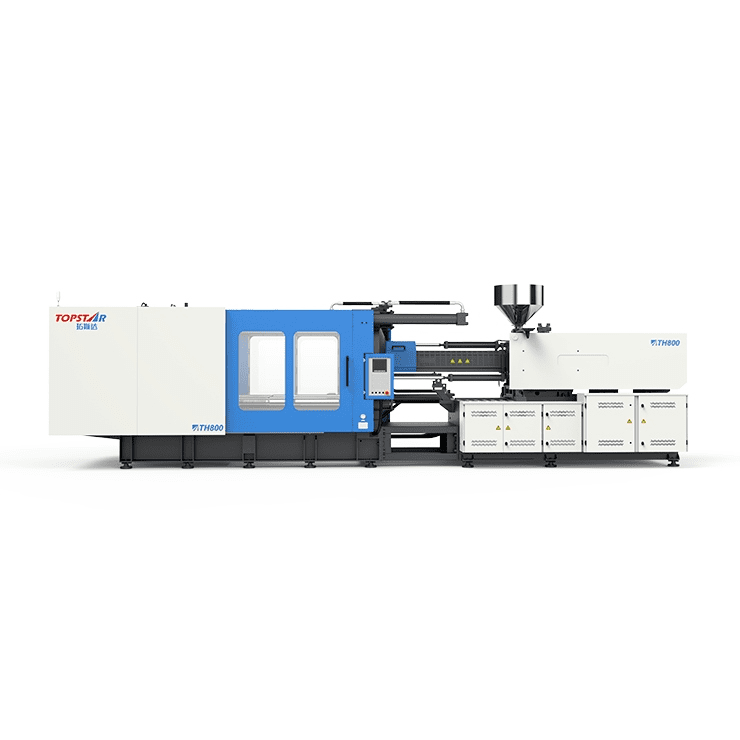

The home injection molding machine is responsible for putting plastic into the mold through the processes of:

- plastic feeding

- Similarly, compression

- Degassing

- Moreover, plastic melting

- injection of liquid plastic into the mold and shaping the product

This system has the following components:

- Plastic Feed Hopper (Hopper)

- Furthermore, Plastic storage compartment (Barrel)

- Heater bands

- In addition, Screw (Screw)

- Non-return Assembly

- Nozzle

Home injection molding machine Plastic feeding hopper

Home injection molding machine contains pelletized plastic material for feeding into the mixing chamber.

b, Plastic storage compartment

Contains plastic heated by heating rings

c, Heating rings

Keep the temperature in the plastic container always in a state of molten plastic. On a plastic injection molding machine, the heating rings are set to different temperatures to create the right temperature zones for the injection molding process.

d, Screw

Has the function of compressing, melting and creating pressure to push the plastic to flow into the mold cavity

The screw has a structure of 3 zones: the plastic feeding area, the compression zone and the dosing area

Self-opening regenerative or self-opening return valve

This unit consists of a wedge guard, a screw head and a seat. The function of creating a stream of plastic shot into the mold

As the screw recedes, the wedge-shaped barrier moves towards the nozzle and allows the plastic to flow towards the front of the screw head. and when the screw moves forward, vice versa

2. Classification of Injection Molding Machines.

- Thermoplastic injection machine

- Thermosetting plastic injection machine

Types of plastic injection machines

- Vertical plastic injection machine

- Horizontal plastic injection machine

Plastic injection machine models:

Spray line: axial spray (segmented line); Follow the road

Clamping system: Has the function of opening and closing the mold, creating clamping force to hold the mold during cooling & push the product out of the mold at the end of an injection molding cycle. Furthermore, this system includes:

- The bottom of the machine

- Pliers assembly

- Moreover, movable plate

- Fixed plate

- Similarly, the connecting rods

Hydraulic plastic injection machine

The hydraulic home injection molding machine is a type of plastic injection machine that uses a hydraulic system. It is to open and close the mold and maintain that clamping force. Furthermore, the hydraulic system also makes the screw rotate, and move back and forth. Similarly, it gives force to the push pin… This system includes: pump, valve, motor, pipeline and oil tank..etc.

Electric plastic injection machine

Electric plastic injection machine is a plastic injection machine that uses a servo motor to adjust the mold opening, closing and mold pliers, pushing the backing pin. Some of these machines are also equipped with servo motors to control the back and forth movement of the screw…

As far as I know, the electric plastic injection machine appeared on the market around 2005 in Japan.

3. Should choose an electric plastic injection machine or a hydraulic plastic injection machine?

To give a sincere and accurate advice in choosing an electric home injection molding machine or a hydraulic plastic injection machine is really not easy. Each type of machine has its own advantages and disadvantages.

Therefore, depending on the specific job, you can buy the appropriate type of plastic injection machine to bring the highest economic efficiency. Below I will compare these two plastic injection machines according to the basic criteria so that readers can make the best decision.

About power consumption:

Electric plastic injection machines save you 20-40% of electricity consumption compared to hydraulic plastic injection machines. This is also understandable because the hydraulic plastic injection machine uses a hydraulic system.

This also includes pumps and motors to recycle hydraulic oil to supply the whole system even when there is no requirement.

As for the home injection molding machine controlled by Servo motor, it only works and generates power loss when it is necessary to close, open the mold, move the screw…

Work productivity of home injection molding machine

The hydraulic plastic injection molding machine has a faster opening and closing speed than the electric plastic injection machine because the efficiency of this type of motor at the moment is lower. This is also a disadvantage of the electric motor because if the opening and closing takes too long, it will affect the injection molding cycle.

However, if the products need a lot of time to cool, then using an electric plastic injection machine is not a disadvantage. Besides, due to the use of servo motor to open – close the mold, clear and move the screw, the travel distances are very accurate and safe.

For products that require large injection pressure and large mold clamping force, an electric plastic injection machine is not a good choice. Similarly, it is easy to be damaged by the parting surface.

Advantages of home injection molding machine

A huge advantage of the home injection molding machine is that there are no hydraulic pumps, pump motors, valves, and pipes. It is much lighter and neater than the hydraulic plastic injection machine. A typical hydraulic plastic injection machine needs about 300 liters of hydraulic oil to operate, which is also a small cost. In addition, during operation, I noticed that the electric plastic injection machine operates more quietly than the hydraulic plastic injection machine.

Plastic injection machine and working principle of plastic injection machine

Currently, plastic products are widely used in daily life and work all over the world. Plastic injection molding technology is being widely applied in the field of manufacturing plastic products. Plastic injection molding machine adapts well to a wide range of products, has high production capacity, and is easy to automate.

In this article, we have introduced you to information related to home injection molding machine. You can better understand before you intend to order a machine for your business or production facility.

Working principle of plastic injection machine

The working principle of plastic injection molding machine: is to inject molten plastic under a great pressure into the forming part (mold) to ensure that the hot plastic is filled and cooled to shape the product.

Plastic injection is a cyclic process, with each cycle including: dosing — molten plastic — injection pressure filling — cooling — taking mode. Remove the excess resin and then re-close the next cycle.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2021/12/31

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2021/12/31

- Star Case | Topstar helps Santong upgrade its intelligent plant 2021/12/31

- Topstar Special | National Science and Technology Workers Day 2021/12/31

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC