The Hobby Injection Molding Machine That Wins Customers

2022/01/31 By Topstar

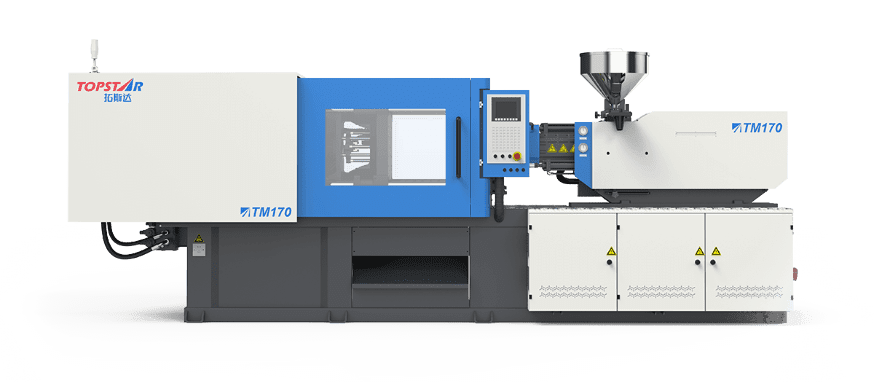

Plastic Injection Machine Structure

Hobby injection molding machine are structured as follows:

- Plastic injection machine construction

- Control and operation system.

- The operation of the press machine is as essential as the control system.

- All models from low to high have this control system.

- The control system helps us to choose the operating plan for each type of plastic product, for each plastic line.

- PLC can fully automate the control system, or it can be partially automated.

In this section, we only give an overview of the control system in the injection molding machine but do not go into details.

Hobby injection molding machine mixing and liquefaction system

Mixing System Material mixing and liquefaction is the area that has the most significant influence on the plastic processing manufacturing technology process.

This system consists of the following main mechanical parts:

- Cylinder barrel of plastic extrusion machine

- Screw Plastic Extrusion Machine

- Heating Resistors

- Plastic input hopper

- Plastic Glue Splitting System

- Product forming mold system

- The plastic product developing system is the mold system.

Plastic injection mold system

Plastic molds come in many forms and complex structures.

Whether plastic products are consistent and good depends significantly on the mold design and manufacturing stage. Hobby injection molding machine must achieve the following properties:

- Sample Standard Profile

- Materials Resistant to temperature, little known heat form

- The surface gloss of the mold must reach a high gloss

- Easily remove the product from the mold

- Mold surface hardness must be high wear resistance.

- Design a cooling system for the mold to dissipate heat during product cooling effectively.

Injection molding support system

- Non-return Assembly

- Nozzle

Clamping, Pushing Mold System in Hobby Injection Molding Machine:

Firstly, this is the Bracket, Clamp, and Push mold system during machine operation. The primary function is to open and close the mold.

Movable Mold Plate

Secondly, when the mold closes, the plastic from the nozzle pushes the liquid plastic into the forming mold. Thirdly comes the stage of cooling the resin in the mold and, finally, opening the mold to take the product out.

Mold Holder System Includes:

- The ejector assembly of the plastic injection machine (Machine ejectors).

This mechanism is mainly designed as a Hydraulic Cylinder connected to an X-Section element.

- The mechanical group holds the mold on the hobby injection molding machine (Clamp cylinders).

This is the mechanical part that holds the mold on the frame of the press machine. Duties have the mold firmly during pressing to ensure no pressure loss and product shaping.

- Moveable platen plastic injection mold parts.

Plastic injection mold for injection molding machines always has two parts: one part is stationary, and one part is moving.

- Stationary platen plastic injection mold.

It is the Fixed Part on the mold holder. This Mold part stands still and Shapes the product.

- Tie bars to guide plastic injection molds

However, guide sliders are Round steels, usually with 4 bars. On the Guide Slider will mount the parter. When the hobby injection molding machine opens and closes the mold, the mold pieces will slide on this bar to perform the opening and closing operation.

Operating Principle of Plastic Injection Machine

In this paragraph, the operating principle is as follows:

Plastic raw materials feed into the injection molding machine periodically. After the plasticizer is injected into the mold, the mold’s shape will create the product’s shape.

Most importantly, the mold opening stroke is made to get the product after being shaped and cooled in the mold.

The feature of hobby injection molding machines is that the production process occurs in cycles. The cycle time depends on the weight of the product, the temperature of the mold cooling water, and the efficiency of the mold cooling system.

Injection molding Products

- shaping Product

- pulling

- Quality checking

- Import

The quality and productivity of the product depend on the quality of the injection molding machine and the quality of the mold.

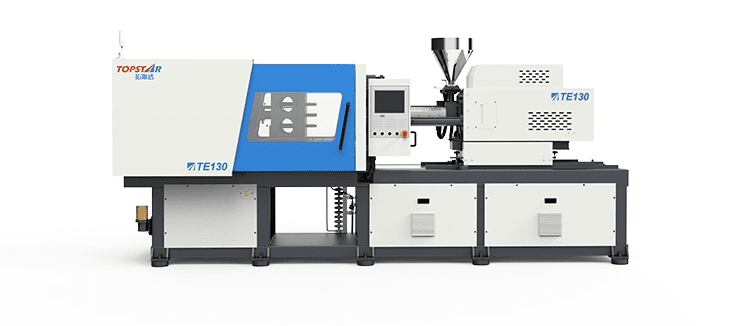

Installation and Alignment of Plastic Injection Machines

The installation and alignment of the plastic injection molding machine is a rather complicated job. Although the manufacturer has built a complete plastic injection machine, each separate part must be disassembled during transportation.

After transporting it to the factory, we assembled the hobby injection molding machine. The critical when Assembling and aligning the plastic injection machine is 4 Tie Bars.

This Guide should align with the center of the Mold. Letting During the slide stroke of the die does not cause these 4 bars to break.

Ensure accuracy in Plastic Molding products.

In plastic injection molding, errors will occur, affecting the quality and aesthetics of plastic products. This article will present you with a fundamental and standard error: the silver error, which means that the plastic injection molded product is discolored.

Recognizing signs

Discoloration, also known as silver core in hobby injection molding machine, is where the surface of plastic products appears silver gray streaks, like scratches. These streaks will distribute in the direction of the plastic flow. With the naked eye, they will feel like plastic flakes.

The surface of the product is split into slabs and scales when cut across. Products with silver will be very susceptible to surface damage when exposed to complex objects.

The correct treatment direction

Moreover, this phenomenon causes the product’s appearance unsatisfactory and undesirable. Therefore, it is necessary to have the correct treatment direction by identifying the precise cause.

The cause of the silver error

Plastic is a type of chemical compound. When the plastic molecules encounter high temperatures, they will slowly decompose. The higher the temperature, the higher the resolution will be. The silver error in the hobby injection molding machine appears due to insufficient gas resolution.

The injection pressure and injection speed will be higher

If the gate size design is small, the injection pressure and rate will be higher. Compressing the air in the press chamber will take place too quickly, causing stress to roll back the air. Tiny air holes then form, causing the silver fault.

Plastic powder is mixed with impurities that cause discoloration

In conclusion, for some objective reason, some unwanted contaminants will integrate into the plastic, or some additive components may be combined in a hobby injection molding machine. Such foreign substances are incompatible with thermoplastics, which can cause discoloration of the product.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/01/31

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/01/31

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/01/31

- Topstar Special | National Science and Technology Workers Day 2022/01/31

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC