Helpful Tips When Buying Plastic Injection Molding Machine

2023/06/12 By Topstar

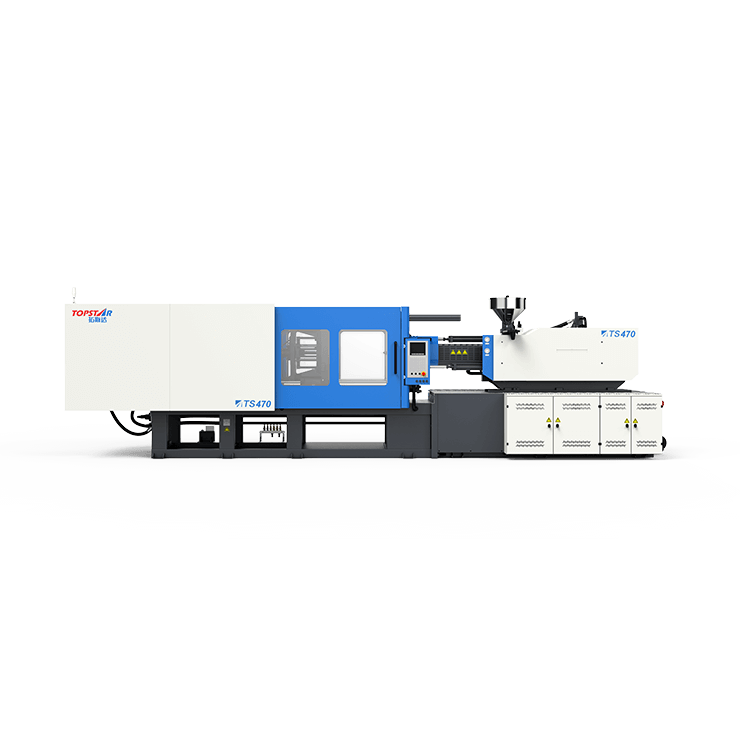

You need the correct machinery to own a business and manufacture your products. A plastic injection molding machine is essential for manufacturing various plastic parts. They are complex machines that require someone with experience to operate them appropriately to meet your needs. Here are some helpful tips for anyone interested in purchasing a new device:

The size of the plastic injection molding machine is an essential factor to consider!

The size of the plastic injection molding machine is an essential factor to consider. It determines how much plastic you can produce at a time and affects the final product’s size. The mold will determine how big your parts are, so if you want small pieces, make sure they are as small as possible when they come out of their molds.

Once you’ve decided on the type of project you must undertake, it’s time to consider purchasing some machinery to help make it happen. It is best to consider owning and operating costs when purchasing an injection molding machine, as these factors can affect the overall expenditure during production by reducing labor costs while increasing the hourly output of the employees who operate these machines daily.

You should consider owning and operating costs when purchasing a plastic injection molding machine!

It would be best to consider owning and operating costs when purchasing a plastic injection molding machine.

The initial cost of the machine is one thing to think about. It would be best if you also considered whether there are any additional costs associated with the purchase. If so, these can add up quickly and make it more expensive than you expected initially.

Operating costs are another important consideration when purchasing an injection molding machine, as operating costs vary depending on the material, how often the equipment is placed, and even where the equipment is located! Running energy-efficient appliances will save you money over time. Still, suppose electricity prices are high in your region. In that case, doing so probably won’t bring many benefits unless there are other benefits like saving time and effort on manual labor tasks.

Choosing a plastic injection molding machine made of the best metal!

If you are interested in building a plastic injection molding machine, knowing that metal is better than plastic is essential. Metal will last longer and be more reliable than plastic because of its durability and strength. However, metal is also more expensive than plastic because it takes more time and effort for workers to create metal parts for machines than make the same amount of features out of plastic.

Since these two materials have advantages and disadvantages when used as injection molding machine parts, many companies choose one according to their needs.

You must also ensure you get the correct plastic type for your project!

You also need to consider the type of plastic you want to use. Different plastics have different properties, and some are more expensive than others, so you must choose the best one for your project. For example, suppose you want your product to be lightweight but still strong enough for everyday use. In this case, ABS is a better fit than PVC or acrylic because it is lighter than other materials like aluminum or wood and has better impact resistance!

Also, consider whether any manufacturing processes are involved in creating this product, such as injection molding machines. Some plastics are easiecost-effectivefective than others when using these types of devices due to their physical properties such as melt flow index (MFI), which measures how easily a material flows through an injection molding machine during production stages.”

You can get quality injection molding machines by knowing what you need and what you’re getting into!

You can get a quality injection molding machine by understanding your needs and the industry you work in, but it’s not that simple. First, make sure that the device is appropriate for your project. If not, there will be problems when the tool fails due to improper use or maintenance.

Secondly, understand how much money is going into buying this equipment before making a purchase decision. This will help determine whether or not it makes sense financially for your business at this time. Also, consider whether other factors, such as reliability and durability, will affect the amount spent on repairs.

To sum up

In short, when you buy a plastic injection molding machine, the above tips are what you need to know. We know this can be overwhelming; with so many options, it’s essential to research and find the one that best suits you and your business needs. If you don’t understand or have any questions, please get in touch with us!

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/06/12

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/06/12

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/06/12

- Topstar Special | National Science and Technology Workers Day 2023/06/12

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC