Facts about High Precision Water Distributor for Plastic Small Industries

2023/07/28 By Topstar

There is a complete industrial line in the small plastic industry, which has a variety of industrial equipment, so today we will talk about high-precision water distributor. It is one of the most essential parts of the plastic manufacturing process. The plastics micro-industry’s need to supply its customers with high-quality polymers requires them to equip their production processes efficiently. Here I will share some facts about plastic small industrial high-precision water distributor, including their importance.

A Water Distributor is an integral part of a plastic processing unit!

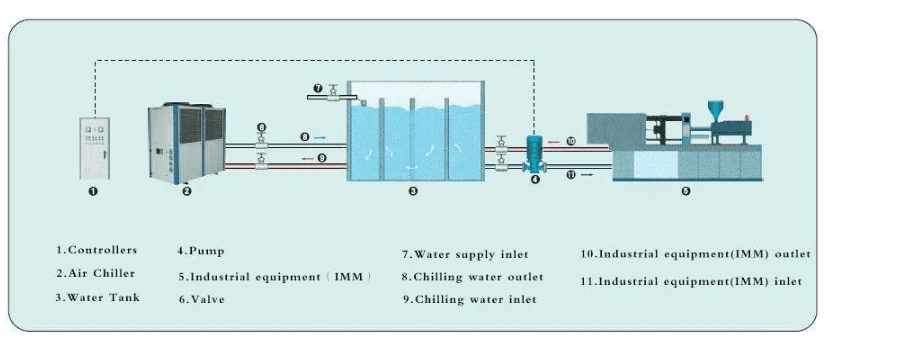

Water distributors are an essential part of plastics processing installations. It is used to supply water to different parts of the plastic industry, such as molds and other equipment. They are suitable for both manual and automated operations, depending on what type your business requires. A water distributor can provide consistent pressure throughout the procedure so that no matter where you place it in your facility or plant, there will always be enough liquid to pump without any stalls due to lack of pressure. One end of the factory building flows from the workshop facility to another location.

A water distributor is a particular machine for the small plastic industry!

A water distributor is a particular machine for water supply to various parts of the small plastic industry. Water distribution, cooling for plastic molding machines and injection molding machines. The primary function of these distributors is to provide high-pressure cooling water through tiny nozzles. Place them wherever you want, inside or outside the plant, as they are portable and have wheels attached. So you can quickly move them according to your requirements anytime during production.

It uses less power, which makes it more efficient than other systems!

You may be wondering, “How does this system work?” It’s pretty simple. High-precision water distributors use less electricity than other systems. Less power also means less maintenance for you and your staff to worry about and less time to troubleshoot any issues that may arise with your system. This is especially beneficial if your small plastic business is in an area with frequent power outages. With traditional water systems, if there is no power during a blackout or brownout, none of your machines can function correctly, as they depend entirely on access to fresh water!

What are the applications of high-precision water distributors?

High-precision water distributors are suitable for the plastics industry. It is one of the most important machines used in the plastics industry as it supplies water to the different parts of the machine. The primary purpose of this machine is to distribute water evenly throughout the plant so that all parts are equally hydrated and do not crack under pressure, causing leaks or other problems. This way, you can save a lot of repair time and money! The system uses less electricity than others and distributes water evenly across the factory floor more efficiently.

High-precision water distributors save your money and enhance your productivity!

High-precision water distributors are a great way to improve product quality, reduce production costs and increase productivity.

Benefits of using a high-precision water dispenser include Reduced energy consumption – Water dispensers are designed to use both hot and cold water, so they can help you save money by reducing the heat required for machines to run.

Longer Product Shelf Life – These systems’ precise temperature control ensures that products stay fresher longer than other products and are less likely to spoil in storage. This translates directly into higher profits for any business selling products online or through brick-and-mortar stores.

Finally we recommend

If you are a small plastic manufacturing business and do not already own a water dispenser, you will buy them as soon as you read this article and know these facts about it. We have often emphasized their importance; you will gain and feel it when using them. At the same time, Topstar is the company that provides equipment for the injection molding processing industry, and we look forward to cooperating with you.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/07/28

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/07/28

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/07/28

- Topstar Special | National Science and Technology Workers Day 2023/07/28

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC