Everything you ought to know about x carve CNC

2022/09/16 By Topstar

Who doesn’t desire something that’s brand-spanking new? Everyone! Yes, you’re right. These days, x carve CNC is quite popular. Do you want to discover the reason? This is why we are here to explain it. Continue reading this post to learn more about the x-carve CNC machine that TopStar offers.

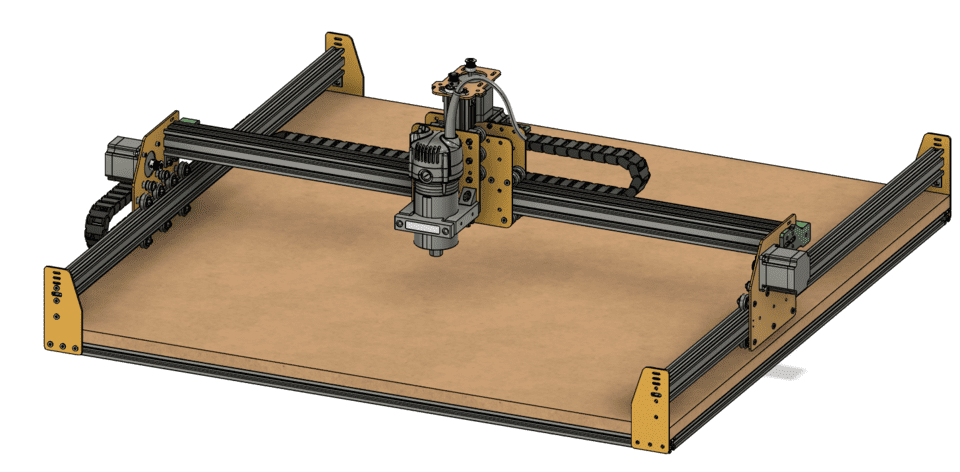

What is an x carve machine?

The x carve CNC is a three-dimensional carving machine that can etch projects out of several materials, including plastics, wood, and other materials. Using a CAD program and vectors as a guide, it transforms wood, plastics such as acrylic, high-density polyethylene, aluminum, and other hard materials into the 3D design that you have envisioned. X carve is also powerful enough to carve through more challenging materials without sacrificing the precision of its cuts. X carve is primarily designed for people who enjoy carving as a hobby. The x-sculpt is only available in one size, which is 1000 millimeters.

How does the x-carve CNC machine work?

First, when the machine is turned on, you will begin designing something. After you have finished creating your project using a CAD/CAM program, use clamps to fasten the carving material to the x Carve workspace. After that, you will need to use the software to transfer your files to your x carve. The design file is then delivered to the motion controller of the x Carve. This data file is known as a code file. The machine can understand anything thanks to the geocode coordinates. An easel is a piece of software that is available for usage on this device. It will generate the appropriate code for your project in an automated fashion. After that, it eliminates the need for guesswork by automatically creating the code necessary to carve your design.

While X Carve CNC is working on carving your item, Easel always maintains control of the spindle. The bit used to inscribe your pattern into the material is stored in the spindle of the x-sculpt. As the machine progresses, the bit cuts away any unnecessary material and is only left with the material essential to your design’s construction. When you are finished, the material left over will be your finished product.

Uses of x carve CNC machine:

You will be astounded to learn that the x-carve CNC machine can be used for various fascinating projects. The x carve distinguishes out from other similar products since it allows you to personalize your setup while keeping the cost to a minimum at the same time. Many people use x carve to make gifts for the people they care about and decorative items for their homes. Additionally, businesses utilize it to manufacture goods to sell. For instance, mailboxes, book stands, and other similar items.

Signs, trays, toys, guitars, games, decorations for the kitchen, and furniture are some of the most typical goods our customers’ design and build. X carve is used by a lot of customers to mill components for larger projects. You can even carve out individual sections that will later be put together to form the final result. Modular furniture, inlays on larger pieces, and components that complement other projects are only some examples of this type of furniture. Making jigs, fixtures, and other devices that speed up the assembly or production of other projects can be accomplished using an x carve.

Benefits of X carve CNC:

⦁ Accuracy:

One of the significant benefits of using an x carve machine is that it provides a high level of accuracy and precision, reducing the likelihood of making a mistake. It creates designs in a three-dimensional format using a computer program, and the output is in that format.

⦁ Time-saving:

Using an X carve to make things can help save time while guaranteeing that they are accurate and exact. To maximize output, you can program x carve to carry out daily or even hourly operations. Because it operates on a computer, it will do your work in a reasonable amount of time while also saving you time.

⦁ Fewer workers:

You should know that when an x-carve CNC machine is used, the number of people needed to make things go down significantly. The machine’s tools can reduce the time spent on production while producing a high output. It is essential to remember that the simpler the design, the fewer people are involved in its creation.

⦁ Customization:

One of the primary advantages of x carve is that it is both open source and customizable, making it simple to build a machine tailored to your specific requirements. Using the x-carve CNC machine, you can personalize your design and hand it over to the device.

- Easy to use:

Both the installation and operation of the x-carve are simple processes. You will become more familiar with your machine by following the precise instructions provided. Customer service is available if questions arise. You need to get in touch with TopStar and ask any questions if you have any.

Where can you buy this machine?

Topstar is pleased to announce that they now offer x carve CNC machines. Our x-cut CNC machine is reliable, long-lasting, and applicable across many industries and delivers a good performance. We provide the training resources needed to install and operate the packaging machine so that you can deal with any potential problems and ensure that the equipment works in the best state.

In general

You are now aware of the specifics of an x-carve CNC machine, how it works, and the many advantages of using one. TopCar is here to assist you in purchasing it if that is something you want. Don’t be shy. Contact us immediately if you’re interested in purchasing our x carve machine.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/09/16

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/09/16

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/09/16

- Topstar Special | National Science and Technology Workers Day 2022/09/16

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC