Detailed information about honeycomb rotor dehumidifier-Solve your problem

2022/09/16 By Topstar

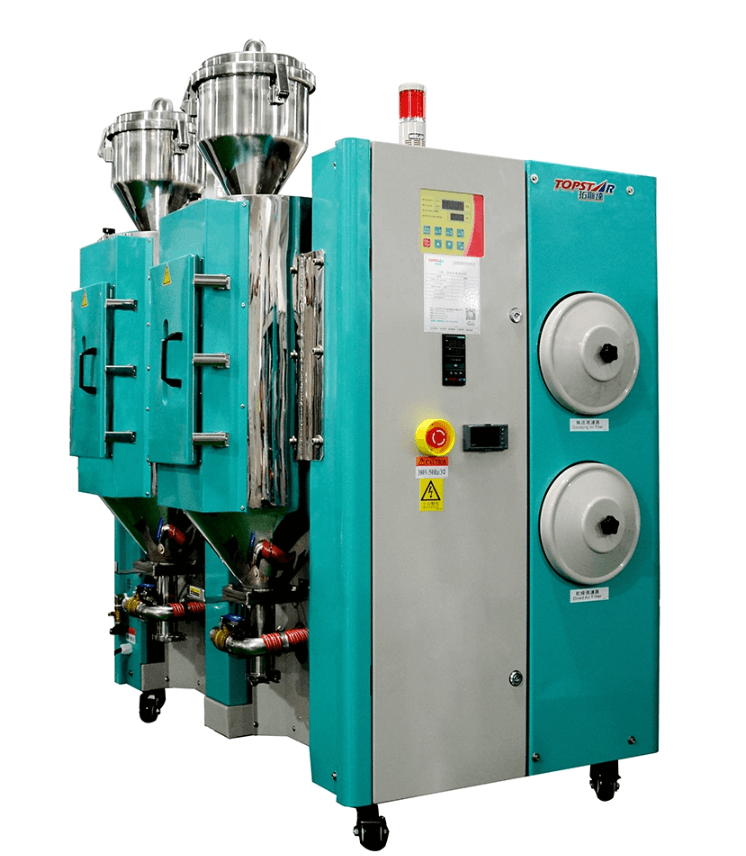

When drying polymers, a honeycomb rotor dehumidifier is typically utilized. They have a lengthy history of application in this sector of the economy. Honeycomb rotor dehumidifiers are the topic of our conversation today, and we are happy to answer any questions you may have. Keep reading the post if you want any more information on the topic.

What are honeycomb rotor dehumidifiers?

Evaporation is the process that honeycomb rotor dehumidifiers employ to remove moisture from the air. They are similar to humidifiers in that they function by the same concept. However, they do not produce steam from water. Wheel dehumidifiers are another name for these devices. Honeycomb dehumidifiers are utilized mainly to dry hygroscopic engineering polymers.

The honeycomb dehumidifier helps with the regulation of humidity. It has a large absorption capacity, is efficient with energy, and has a quick-absorbing speed. Its primary application is in dehumidifying very hygroscopic engineering plastics, which requires high efficiency. To provide efficient drying, a honeycomb rotor is utilized. Under optimal conditions, this rotor can produce dehumidified dry air with a dew point lower than -40 degrees Celsius.

How does a honeycomb rotor dehumidifier work?

The blower draws the moist air into the machine and passes through the heat exchanger. At this point, the air’s water molecules condense into water droplets, and the machine’s cleaned dry air is expelled. Such circulation maintains an optimal interior humidity level.

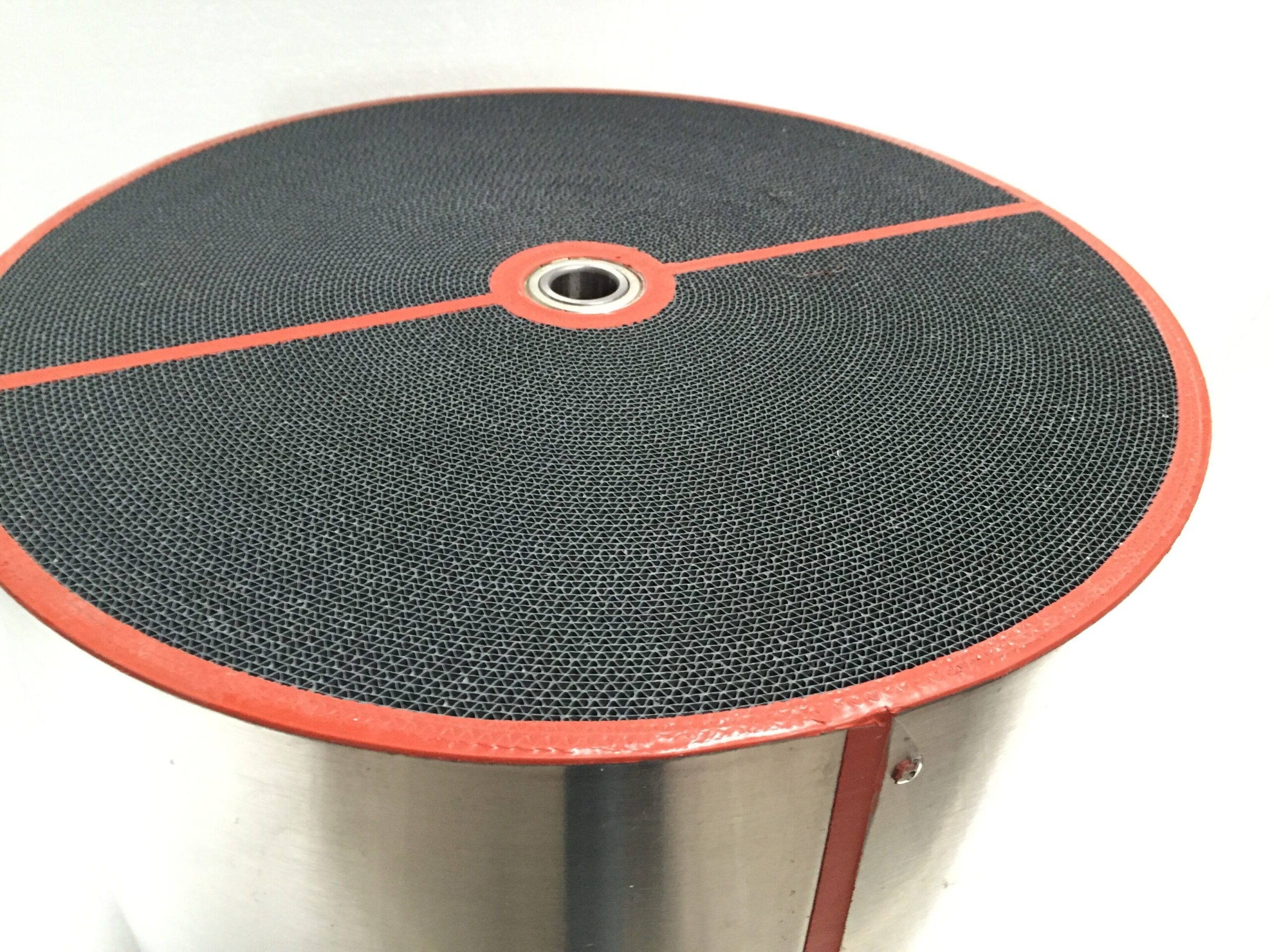

The basic structure of the dehumidification machine is a honeycomb drier wheel that rotates continually. The runner is the most critical component of the dehumidifier’s moisture absorption. Its medium consists of limited ceramics and has been exposed to a high-temperature treatment. A carrier comprised of such materials can significantly reduce moisture absorption. It also has high tensile strength and is better suited for complex working settings. The cellular structure design substantially increases the surface area where the wet air and the moisture absorbent interact, enhancing the dehumidifier’s performance.

Role of the rotor in dehumidification:

The rotors are an integral component of honeycomb rotor dehumidification systems, which maintain the desired humidity level in industrial and commercial settings. When air is forced through the rotor frame, the impregnated media within the frame can effectively remove moisture. The process leads to an overall dryer environment. The rotor is an essential component in the method through which the humidity is removed from the air. Your capacity to remove moisture will increase in proportion to the size of the rotor.

Why do you need a honeycomb rotor dehumidifier?

As a result of the increasing expansion of the worldwide plastics sector, there is now a greater demand for industrial honeycomb dehumidifiers that have been carefully built. Honeycomb dehumidifiers are too essential to disregard their significance. The following are some reasons you need a dehumidifier with a honeycomb rotor.

- The dehumidifier improves the efficiency of the plastics sector, so it is crucial to understand its function.

- This dehumidifier lessens the air’s pollution, which in turn helps reduce the impact of the greenhouse effect and speeds up the drying process.

- Additionally, it improves the quality of the product while it is still covered under guarantee.

- The honeycomb dehumidifier is movable, and it features wheels that are fastened to the base. As a result, you can transfer the dehumidifier to any location that suits your needs.

- To relocate this apparatus does not call for the use of any labor. Therefore, a relatively small amount of work is required for this. In addition to that, this will be inexpensive.

Speeding up of the process:

If the regeneration process is unsuccessful, you must either remove or replace the material from the honeycomb dehumidifier. The honeycomb rotor is divided into two sections for its operation. The standard process is carried out during the first half, while the regeneration process is carried out during the second half. Because of this, removing the desiccant material from the honeycomb dehumidifier will not be an option for you. This will also increase efficiency on your part because you will be able to reuse the same desiccant for the regeneration process. The regeneration process can rapidly remove moisture from the material, which speeds up the drying process.

Features:

- The P.I.D. temperature control technology, which allows for precise temperature regulation during the regeneration process, is used in this series.

- To prevent the honeycomb wheel from becoming contaminated with raw material dust, there is a filter for the air that is returned to the inside.

- Large-scale dryers are an ideal application for the honeycomb wheel type of dehumidification technique.

- It is appropriate for engineering plastics with high hygroscopicity, such as P.E.T., PA, P.C., A.B.S., PBT, and other similar materials.

- Honeycomb rotors have a service life of at least six years and can be washed clean with water.

Where can you buy honeycomb rotor dehumidifiers?

Topstar is your most reliable resource for purchasing honeycomb rotor dehumidifiers of the highest possible quality. The exceptional quality of our items is our number one concern. A one-year guarantee is included with each of our machines. We make our customer care representatives readily available at all times, and they will respond to any comments provided within twenty-four hours. We can deliver the packages within the allotted period, and we have a large inventory of products available. Our clients are significant to us, so we create our products to meet their needs. They are, therefore, of very high quality.

If you cannot use the honeycomb rotor dehumidifier

Suppose you do not have access to a honeycomb rotor dehumidifier. In that case, you run the risk of your production taking significantly longer than it should and experiencing costly pauses in manufacturing as a direct result of an inability to control the humidity effectively. Invest in a honeycomb rotor dehumidifier from TopStar if you never want to be in this circumstance.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2022/09/16

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2022/09/16

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2022/09/16

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/09/16

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar