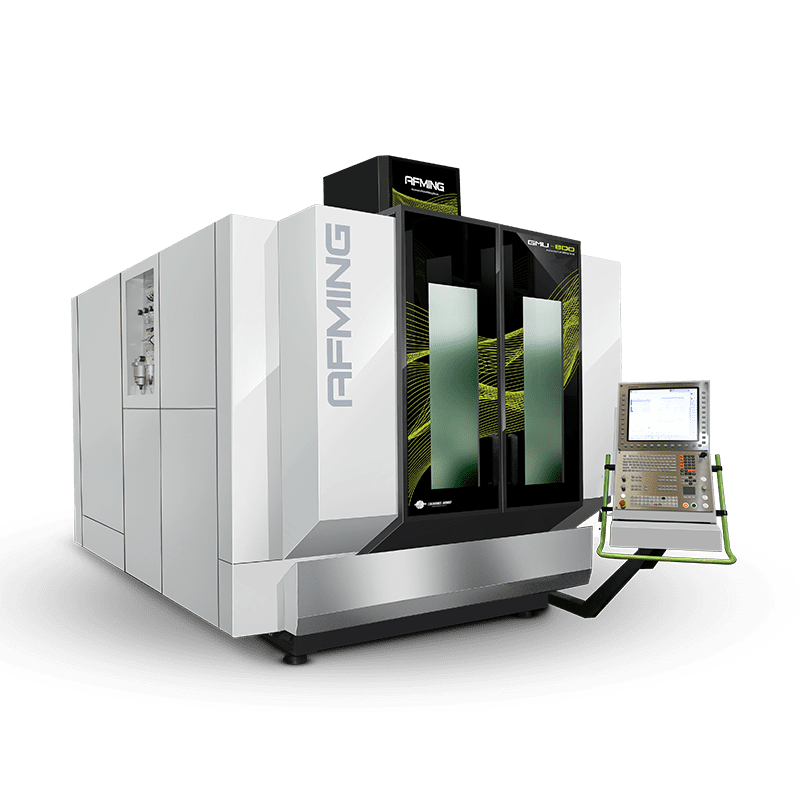

Changing the mold industry with Five Axis Machine Center

2024/01/10 By Topstar

The Five Axis Machine Center has multi-axis linkage control capabilities and can flexibly move in multiple directions to achieve more complex and precise processing tasks. Therefore, it is widely used in the mold industry. Below we will analyze the advantages of the five-axis machining center one by one to better understand how it changes the mold industry.

Precision Advantages of Five Axis Machine Center

The precision advantage offered by a five-axis machining center stems from its ability to approach the workpiece from multiple angles, enhancing accuracy and efficiency. Traditional machining centers, limited to three axes, necessitate repositioning the workpiece for different cuts. In contrast, five-axis machining enables the cutting tool to traverse two additional axes of rotation, eliminating the need for repositioning. This multi-axis motion significantly improves accuracy by allowing continuous tool engagement, minimizing errors associated with workpiece reorientation.

Continuous tool engagement and dynamic motion capabilities of five-axis machining centers contribute to achieving superior surface finishes. This capability is crucial in mold-making industries, where high-quality surface treatment is vital for aesthetics and functionality. The broader tool range in the five-axis machine accommodates complex molds without compromising accuracy, ensuring precise and smooth surfaces.

Complex geometric shapes

Five-axis machining centers leverage synchronized motion across multiple axes to craft intricate details, undercuts, and complex geometries that are challenging to achieve with traditional methods. By approaching the workpiece from various angles, the need for tool changes is minimized, saving time and enhancing accuracy. This approach allows complex features to be completed in a single setup, reducing setup time and ensuring consistent accuracy throughout the machining process. Moreover, five-axis machining facilitates the creation of optimized cooling channels within molds, improving heat dissipation and shortening cycle times during molding. Their versatility speeds up the testing and validation of mold designs before mass production.

Five Axis Machine Center speeds up mold production

The synchronized motion along multiple axes in five-axis machining centers enables the simultaneous machining of numerous mold surfaces. This eliminates sequential operations, reduces overall machining time, and accelerates production cycles. Equipped with high-speed cutting capabilities for efficient material removal rates, these machining centers expedite roughing and finishing processes, saving time in mold production. Our five-axis machining centers adopt adaptive machining strategies that adjust cutting parameters using real-time feedback. This ensures optimal machining conditions, minimizes tool wear, and maximizes overall machining efficiency.

Five-axis machining center’s mastery of materials

Five-axis machining centers excel in the precision machining of various metal alloys commonly employed in mold production, including aluminum, steel, and titanium. Their versatility extends to plastics and polymers, crucial materials in molding applications. Whether crafting injection molds or thermoforming molds, these centers deliver the precision needed to produce intricate plastic parts with high repeatability. With robust cutting tools and advanced cooling systems, they efficiently process tool steel, ensuring the durability and performance of molds. This versatility empowers manufacturers to handle diverse materials and optimize mold production for various industries.

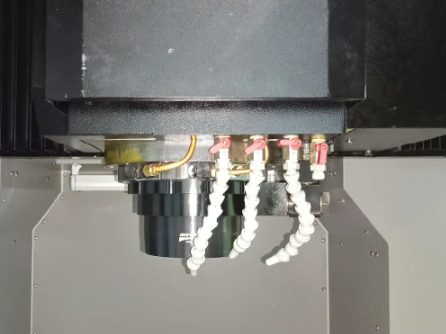

Structural details of Five Axis Machine Center

Implementing a design methodology combining finite element analysis and dynamic optimization on their structures significantly enhances each machine tool component’s static and dynamic characteristics. This approach ensures the machine tool’s overall rigidity, stability, and dynamic accuracy. Extending to cooling and chip management systems, advanced cooling mechanisms circulate coolant to dissipate heat generated during machining. These systems help maintain consistent temperatures, preventing thermal distortion of machine components and workpieces. The coolant, typically a mixture of water and cutting fluid, is precisely directed to the cutting area for efficient heat absorption and chip evacuation. Five-axis machining centers incorporate chip evacuation systems that utilize a combination of air and coolant to remove chips from the work area swiftly. This prevents chip interference with the cutting process and enhances overall machining efficiency.

Bringing more precise machining to the mold industry

The five-axis machining center combines precision, versatility and efficiency to bring more precise manufacturing processes to mold production and complex parts. It can easily and efficiently process a variety of materials, provide perfect surface finish, and complete complex geometric shapes in one clamping. Advanced structural design and an integrated cooling/chip management system further improve its performance, ensuring stable output and extended tool life. For industries that focus on speed, precision and adaptability, the five-axis machining center is the most suitable mold processing solution.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/01/10

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/01/10

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/01/10

- Topstar Special | National Science and Technology Workers Day 2024/01/10

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC