News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2025/01/20 By: Topstar

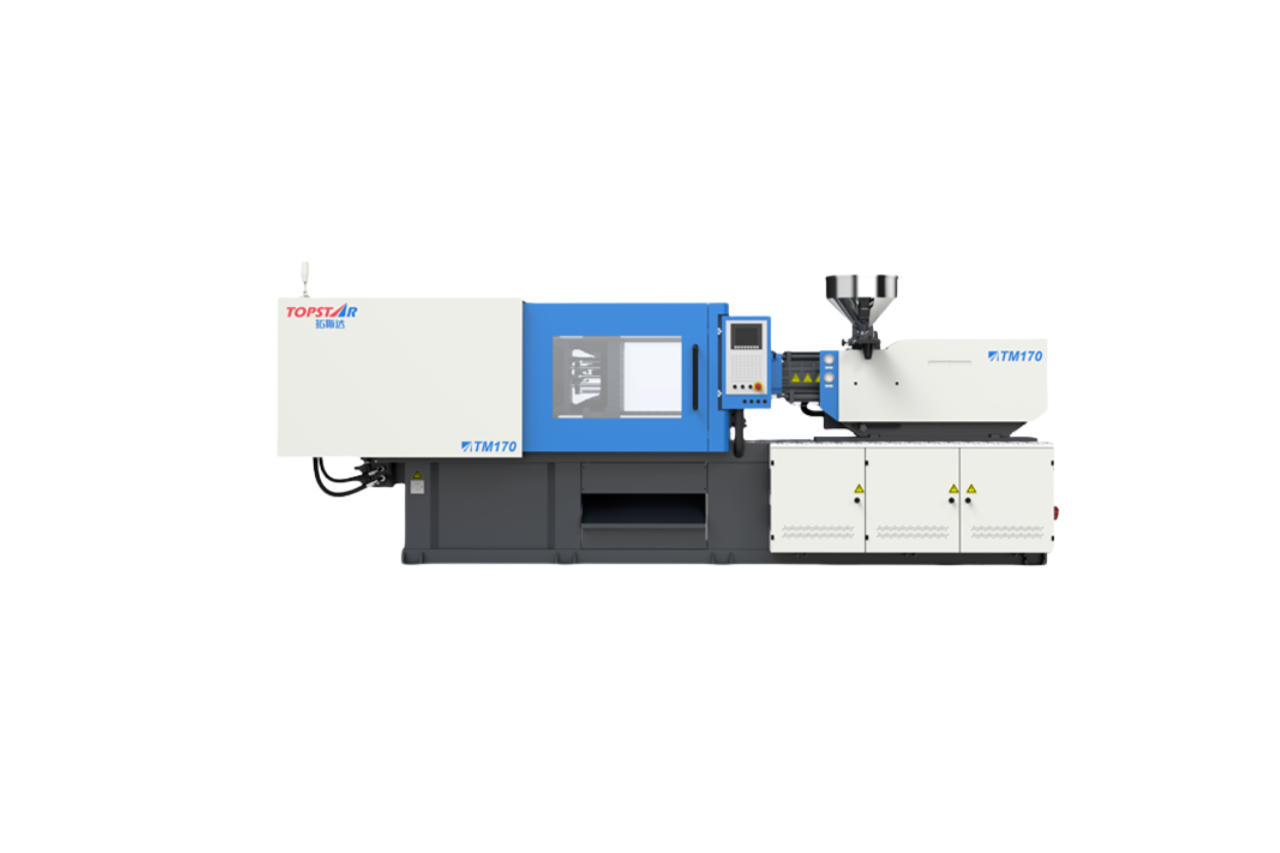

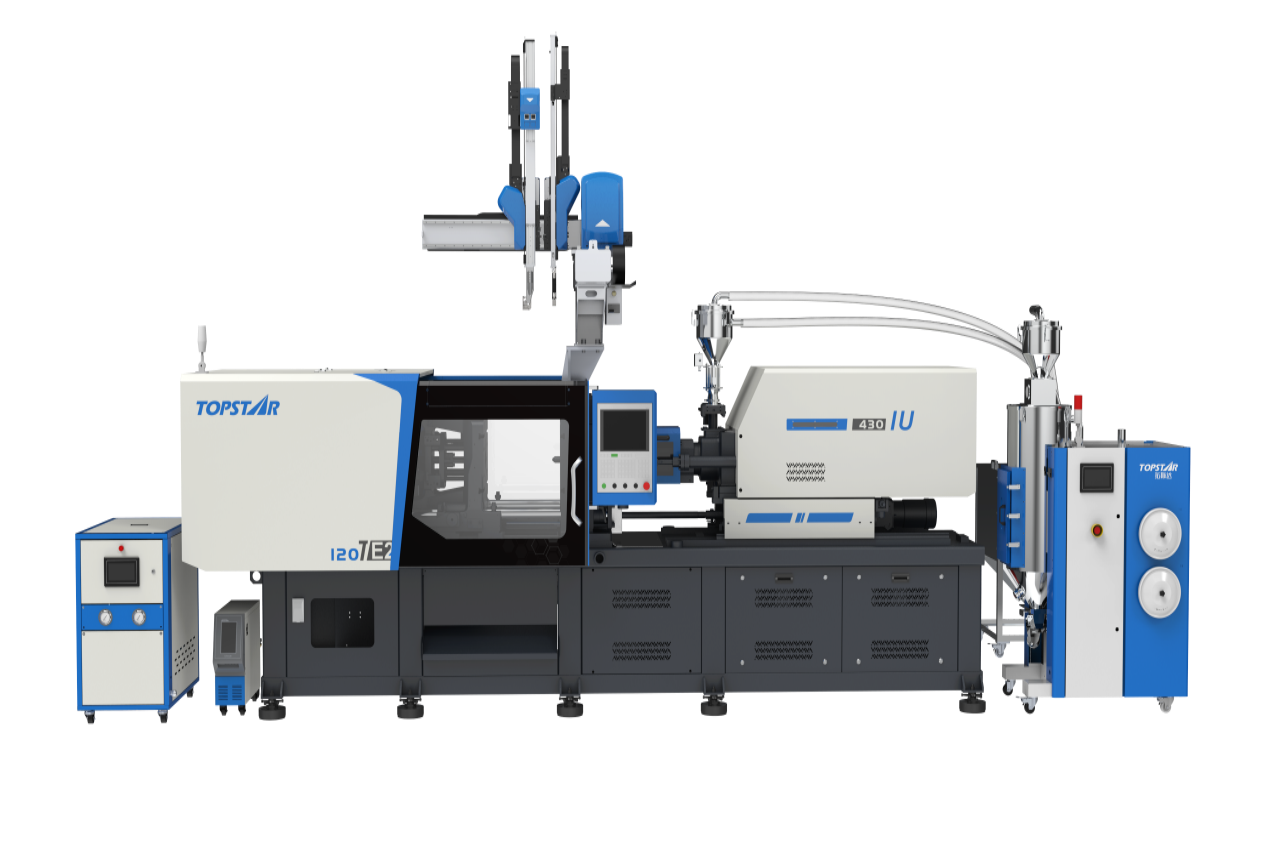

How do plastic molding machine facilitate the production of complex precision plastic parts?

Producing complex and precise plastic parts is a key task in optics, consumer electronics, and consumer goods. In the face of the wave of digitalization, intelligence, and automation in the manufacturing industry, many companies have introduced advanced intelligent plastic molding machines to create highly automated workstations and production lines to meet the needs of high-quality,… Continue reading How do plastic molding machine facilitate the production of complex precision plastic parts?

-

2025/01/17 By: Topstar

SCARA robots developed explicitly for the new energy industry

Countries worldwide are at the forefront of energy transformation, and various new energy fields have emerged, including photovoltaics and lithium batteries. Whether it is the silicon wafer, battery, and component production lines in the photovoltaic industry or the process sections of core making, assembly, chemical composition, and module PACK in the lithium battery industry, there… Continue reading SCARA robots developed explicitly for the new energy industry

-

2025/01/15 By: Topstar

How do SCARA robot make production lines more flexible and agile?

SCARA robot is essential robotic tools in modern manufacturing production lines. They differ from traditional industrial robots and are specially designed to provide high-speed, high-precision, and highly flexible automated production. In this article, we will share with you how SCARA robots can help improve the flexibility and agility of production lines. From faster cycle times… Continue reading How do SCARA robot make production lines more flexible and agile?

-

2025/01/13 By: Topstar

Injection molding machine: Serving the Vietnamese medical consumables market

Vietnam is a crucial service point for Topstar’s overseas market localization strategy. Vietnam’s medical consumables market is growing at an annual rate of 10%. Faced with huge market demand, Topstar’s overseas operations team demonstrated efficient, precise, and reliable overall solutions for injection molding medical bottle caps in the medical consumables industry at Vietnam Plas2024. Topstar’s… Continue reading Injection molding machine: Serving the Vietnamese medical consumables market

-

2025/01/10 By: Topstar

Electric injection molding machines that save energy and reduce costs for medical companies

Medical products are sterile and clean, so their production environment must be a dust-free workshop. At the same time, in the current economic environment, medical companies are looking for a “cost-reducing and efficiency-increasing” production method. For manufacturing companies, reasonable energy layouts and effective management of production processes are essential to reduce operating costs, and low-energy… Continue reading Electric injection molding machines that save energy and reduce costs for medical companies

-

2025/01/08 By: Topstar

Plastic injection molding machine solutions specifically designed for PET materials

The packaging bottles commonly used in daily chemical products are mainly made of PET material. This material has high viscosity and is sensitive to temperature. Improper temperature can easily cause poor product permeability and uneven wall thickness, resulting in waste of raw materials and increased production costs. If the preform is not suitable during injection… Continue reading Plastic injection molding machine solutions specifically designed for PET materials

-

2025/01/06 By: Topstar

What changes and impacts does the emergence of intelligence bring to injection molding machines?

The entire industrial manufacturing field has moved from automation to intelligence. In injection molding equipment, intelligence is Topstar’s core competitiveness. The intelligent equipment we develop covers control systems, servo drives, vision, artificial intelligence, industry solutions, and underlying technologies. Integrating artificial intelligence (AI) and intelligent technology has redefined manufacturers’ production processes, quality assurance, and operational efficiency.… Continue reading What changes and impacts does the emergence of intelligence bring to injection molding machines?

-

2025/01/03 By: Topstar

How does the mould temperature controller contribute to the longevity of molds?

In injection moulding production, properly managing temperature during the moulding process is one key factor in extending mould life and reducing the risk of damage. We can use a mould temperature controller to achieve mould temperature regulation throughout the injection moulding process. In this article, we will share the role of mould temperature controllers in… Continue reading How does the mould temperature controller contribute to the longevity of molds?

-

2024/12/30 By: Topstar

How can I avoid production bottlenecks with the right injection molding machine?

Injection molding automation technology has matured, and the injection molding machine market is gradually developing in the direction of intelligence. Today’s customers are concerned about equipment stability, product quality, delivery time, how to improve manufacturing, and how to provide more reliable product services, which is also the production bottleneck faced by many manufacturers engaged in… Continue reading How can I avoid production bottlenecks with the right injection molding machine?

-

2024/12/27 By: Topstar

To be a smart equipment and world-leading injection molding machine manufacturer

Intelligent and efficient technologies have covered the current manufacturing industry. From traditional manual production to mechanized manufacturing to intelligent production, intelligent manufacturing has become a key force in promoting industrial transformation and upgrading. As a manufacturing enterprise, Topstar will enter a new round of development and become a global leader in intelligent equipment service providers.… Continue reading To be a smart equipment and world-leading injection molding machine manufacturer

-

2024/12/25 By: Topstar

Plastic injection molding equipment suitable for high-end manufacturing industries

Plastic injection molding equipment has become essential in aerospace, electronics, electrical appliances, automobiles, etc. In these high-end manufacturing industries, the auxiliary equipment around the injection molding machine and the materials and production processes used must meet the most stringent standards and put forward higher requirements. Therefore, the plastic injection molding equipment created by Topstar can better… Continue reading Plastic injection molding equipment suitable for high-end manufacturing industries

-

2024/12/23 By: Topstar

What is a Linear guide, and why is it important in plastic injection molding machines?

Plastic injection molding machines can efficiently and accurately produce a variety of products. Topstar uses linear guides and specialized components that improve the molding process’s accuracy, stability, and overall performance to make the injection more accurate and stable. Linear guides ensure that plastic injection molding machines can continue to produce high-quality parts even in high-volume,… Continue reading What is a Linear guide, and why is it important in plastic injection molding machines?